DOI: https://doi.org/10.1016/j.plipres.2024.101275

PMID: https://pubmed.ncbi.nlm.nih.gov/38280491

تاريخ النشر: 2024-01-26

أكسدة الدهون في المستحلبات: رؤى جديدة من العقدين الماضيين

للاستشهاد بهذه النسخة:

أكسدة الدهون في المستحلبات: رؤى جديدة من العقدين الماضيين

معلومات المقال

الكلمات المفتاحية:

المستحلبات

قطرات الدهون

واجهة

مضادات الأكسدة

المستحلبات

التأكسد المشترك

الملخص

تشكل أكسدة الدهون المصدر الرئيسي لتدهور الأطعمة الغنية بالدهون، بما في ذلك المستحلبات الغذائية. إن تعقيد التفاعلات المعنية، بالإضافة إلى الطلب المتزايد من المستهلكين على الأطعمة الأقل معالجة والأكثر طبيعية، يؤدي إلى تحديات إضافية في السيطرة على هذه الظاهرة. تقدم هذه المراجعة لمحة عامة عن الرؤى التي تم اكتسابها على مدى العقدين الماضيين حول فهم أكسدة الدهون في الزيت في الماء.

1. المقدمة

للتحكم في هذه الظاهرة، لا سيما في المنتجات التي تحتوي على كمية عالية من الأحماض الدهنية (البولية) غير المشبعة التي تكون حساسة بشكل خاص للأكسدة. يمكن أن تحدث أكسدة الدهون من خلال ثلاثة مسارات رئيسية: الأكسدة الإنزيمية عبر عمل إنزيمات مثل

- المؤلف المراسل.

** المؤلف المراسل في: INRAE، UR BIA، نانت 44300، فرنسا.

عنوان البريد الإلكتروني: مارie.hennebelle@wur.nl (م. هينيبيل).

الليبواوكسيجيناز، الأكسدة الضوئية من خلال تنشيط مادة حساسة بواسطة الضوء والأكسدة الذاتية. بينما يتم عادة التحكم في الأولين بشكل جيد في المنتجات الغذائية من خلال المعالجة الحرارية والتعبئة، تظل الأكسدة الذاتية تحديًا، لا سيما لتلبية الطلب المتزايد من المستهلكين على منتجات أكثر استدامة وطبيعية (أي، ملصق نظيف). تحتاج المنهجيات الحالية لمنع أكسدة الدهون (أي، تخزين سلسلة التبريد، التعبئة في فراغ أو جو محكم، إضافة مضادات أكسدة صناعية) إلى إعادة النظر، وتظهر اتجاهات جديدة، بما في ذلك استخدام مضادات أكسدة أكثر طبيعية من مستخلصات النباتات، وتطوير مكونات معاد تدويرها من الجوانب الجانبية لصناعة المواد الغذائية، وإدخال مكونات منخفضة أو معالجة بشكل خفيف، أو زيادة استخدام المستحلبات النباتية.

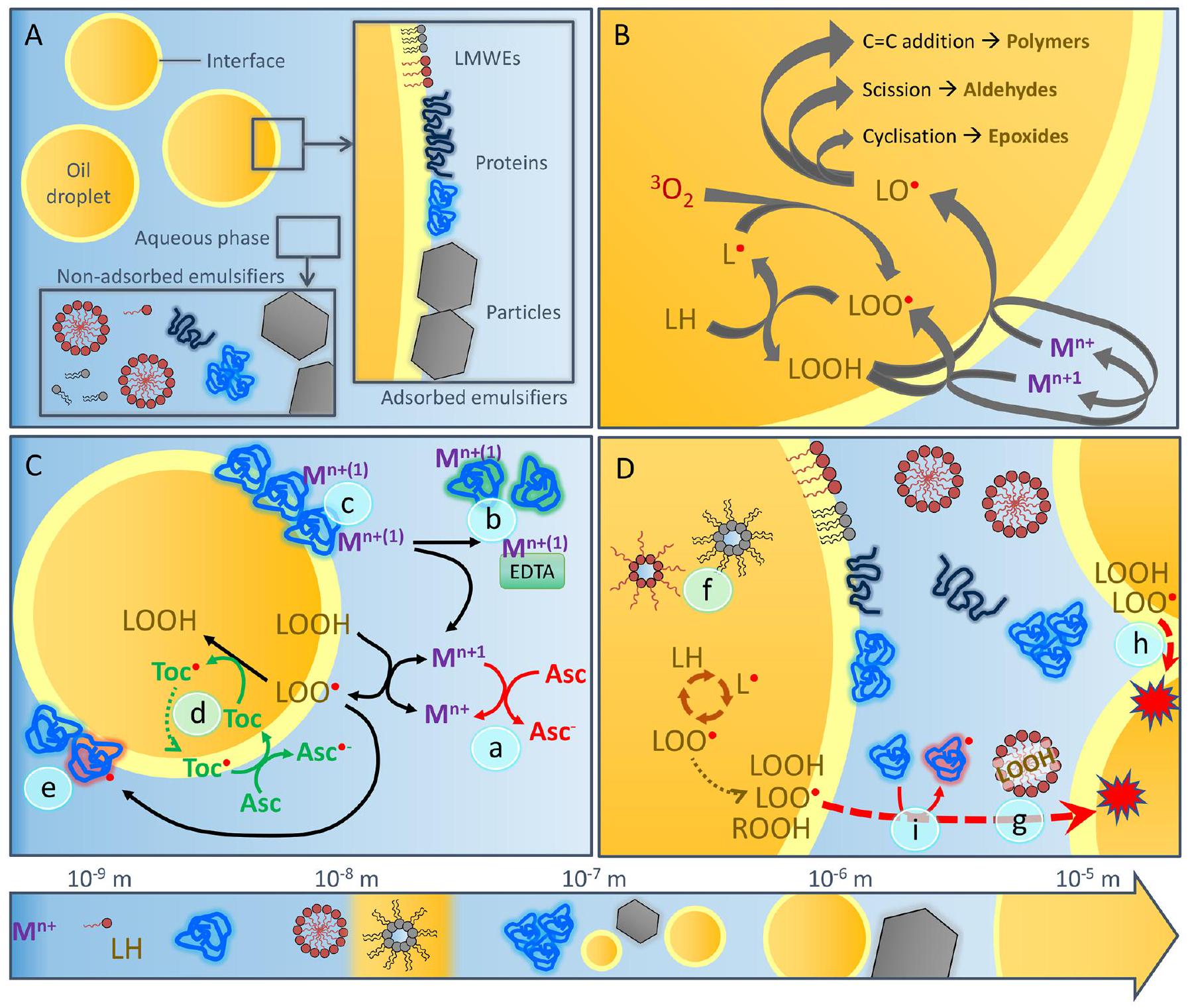

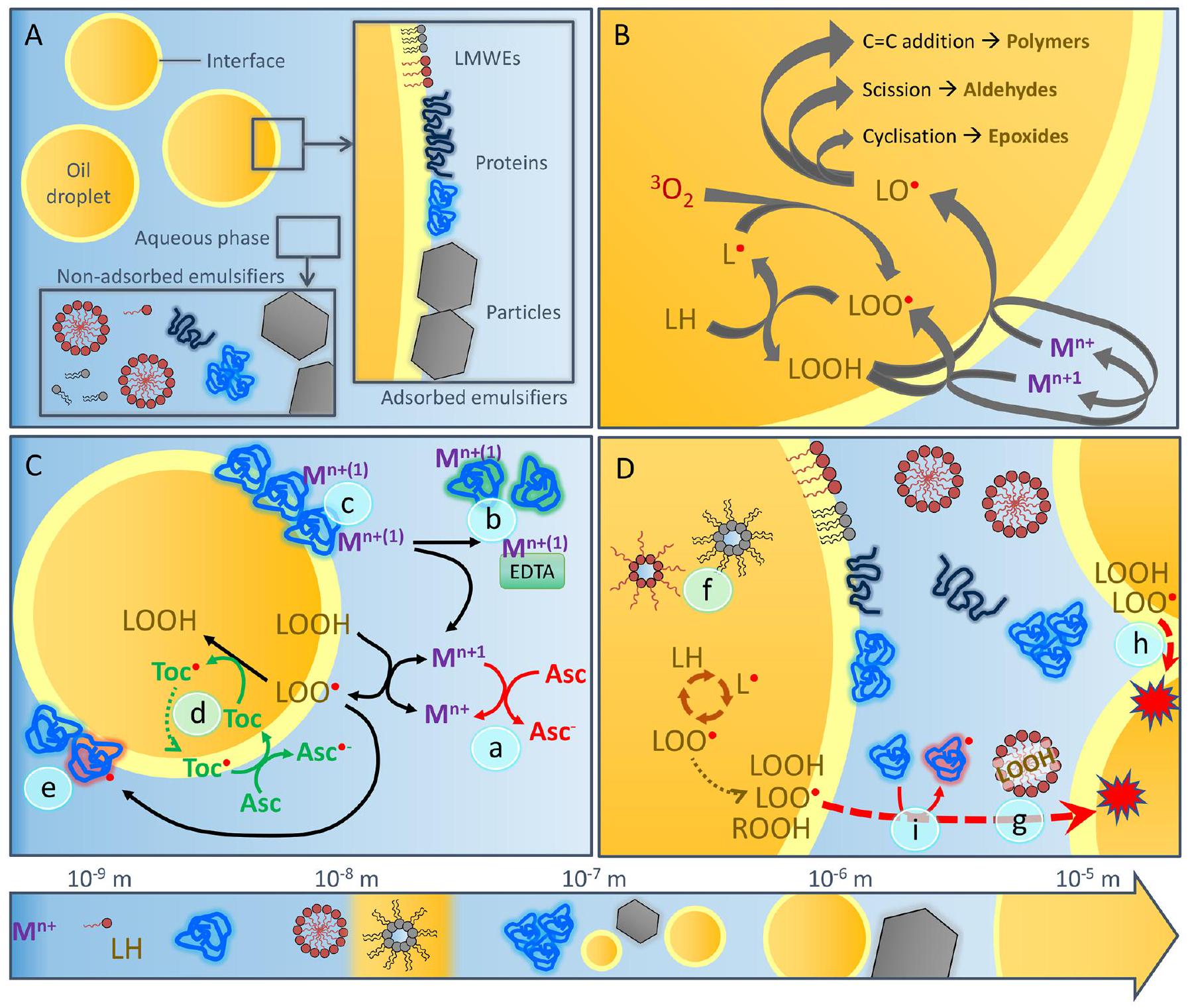

الحليب، تركيبات الرضع، المنتجات القائمة على الألبان، المايونيز، الصلصات، بالإضافة إلى الأدوية، مستحضرات التجميل، ومنتجات العناية الشخصية. تتكون هذه المستحلبات من قطرات زيتية موزعة داخل مرحلة مائية مستمرة ومستقرة بواسطة جزيئات نشطة سطحياً، والتي تمتص عند واجهة الزيت والماء. من المعروف أن واجهة الزيت والماء تلعب دوراً حاسماً كونها الموقع الذي تتلامس فيه الدهون والأكسجين والعوامل المؤكسدة (للمراجعات، انظر [3،4]). المساحة الكبيرة للواجهة التي توجد عادة في المستحلبات تعزز تعرض الدهون للعوامل المؤكسدة، وبالتالي تسرع من أكسدة الدهون مقارنة بالزيوت السائبة. العديد من العوامل، مثل حجم القطرات، التركيب الواجهوي، نوع المستحلب، التقسيم والتفاعل للعوامل المؤكسدة والمضادة للأكسدة يمكن أن تؤثر على عملية أكسدة الدهون في الأطعمة المستحلبة، مما يجعل من الصعب فهم السيطرة على التفاعلات بالكامل، وبالتالي، تبرير استراتيجيات التركيب.

2. آليات أكسدة الدهون في المستحلبات الزيتية في الماء

2.1. الخصائص العامة للمستحلبات وواجهات الزيت والماء

كثافة القطرات، مما قد يؤدي إلى ترسيب القطرات بدلاً من التكوين. تنشأ قوى شعرية جانبية جذابة بين الجسيمات المحبوسة داخل الغشاء السطحي من تشوه واجهة السائل حول الجسيمات، مما يمنح الطبقة السطحية استقرارًا ميكانيكيًا عاليًا وصلابة. هذا، جنبًا إلى جنب مع الطاقة العالية للامتزاز للجسيمات بمجرد امتصاصها، يمنح هذه المستحلبات استقرارًا فيزيائيًا عاليًا، خاصة فيما يتعلق بمقاومة التكتل [15،23].

2.2. نظرة عامة عالمية على مسارات أكسدة الدهون

دورة انتشار أكسدة الدهون. يتم تعديل دورة الأكسدة والاختزال المعدنية في الشكل 1B بشكل كبير من خلال وجود عوامل اختزال قابلة للذوبان في الماء، مثل حمض الأسكوربيك، التي تساعد في تجديد المعادن الانتقالية ثنائية التكافؤ (الآلية (أ) في الشكل 1C) وبالتالي تظهر تأثيرًا مؤكسدًا [39]، أو خافضات المعادن (الآلية (ب) في الشكل 1C)، وبالتالي لها تأثير مضاد للأكسدة في الحالة الأخيرة.

2.3. ما وراء المسار الكلاسيكي لأكسدة الدهون

منتجات غذائية. ومع ذلك، كما سيتم تسليط الضوء عليه بمزيد من التفصيل في الأقسام التالية، فإن واجهة الزيت والماء في

2.4. الدقة الزمانية والمكانية لأكسدة الدهون في المستحلبات

2.4.1. الدور المركزي للواجهة بين النفط والماء

2.4.2. تعديل حركيات الأكسدة من خلال تشكيل الهياكل الغروية داخل المرحلة الزيتية

2.4.3. النقل عبر المرحلة المائية المستمرة

أوكتادكان [26،28،98،99]، ومنتجات أكسدة الدهون الثانوية المحددة التي تحمل مجموعة هيدروبيروكسيد (مثل 4-هيدروبيروكسي 2-نونينال)، والأحماض الدهنية الحرة (مثل حمض اللينوليك)، بالإضافة إلى مركبات الأكسدة الثانوية (مثل 2،4-ديكادينال)، يمكن أن تنتشر عبر نظام المستحلب وقد تنشر تفاعلات أكسدة إلى قطرات الدهون المجاورة [27،99-101]. أشارت التجارب التي أجريت باستخدام قياس التدفق الخلوي إلى أن النقل المساعد بالميكل هو آلية نقل نشطة في المستحلبات النموذجية O/W [100]. أكدت الدراسات التي استخدمت مستحلبات نموذجية معدة بعناية أن هذه الآليات النقل محدودة بمنتجات أكسدة الدهون المحددة؛ على سبيل المثال، الهيدروبيروكسيدات المرتبطة بعمود TAG ليست عرضة للنقل، ربما لأن إدخالها في القلب الكاره للماء للميكل السطحي ليس ممكنًا من الناحية الاستيريو، بينما الجزيئات الصغيرة القابلة للذوبان في الماء هي [27].

2.4.4. تفاعلات الأكسدة داخل المرحلة المائية المستمرة

2.5. نهج النمذجة

بين العينات ذات التغيرات المحددة (مثل، تركيزات مختلفة من مضادات الأكسدة) وقد تم استخدامها حتى للتنبؤ بعمر التخزين للمواد المستحلبة، مثل المايونيز. من ناحية أخرى، يمكن أن تكون تفسير معلماتها معقدًا لأنها لا ترتبط مباشرة بمعلمات النظام نفسه (مثل، تركيبة العينات أو ظروف الحضانة) ولا تأخذ في الاعتبار سلسلة التفاعلات الكاملة المعنية. مؤخرًا، تم اقتراح نموذج حركي آلي أكثر شمولاً في الزيوت السائبة، مع الأخذ في الاعتبار التفاعلات المتعددة المعنية في أكسدة الدهون، ونقل الكتلة للأكسجين، بالإضافة إلى التركيبة الأولية للزيت. يقدم هذا النموذج ميزة تمكين التنبؤ بعمر التخزين لزيوت نباتية مختلفة مخزنة تحت ظروف أكسجين مختلفة، لكنه يظل محدودًا بالزيوت السائبة. في المستحلبات O/W، تم إظهار نموذج حركي يدمج حركية التفاعل ونقل الكتلة لوصف عملية الأكسدة بشكل جيد في المستحلبات المدعمة بخمسة مستحلبات مختلفة.

3. تأثير تركيبة المستحلب وبنيته على أكسدة الدهون

3.1. تأثير معالجة المستحلب والخصائص الهيكلية على أكسدة الدهون

الفرق بين العناصر الدوارة والثابتة لتحفيز القص من أجل تفكك القطرات، ولكنها عادة ما تتمتع بكثافة طاقة منخفضة، مما يجعل من الصعب إنشاء قطرات صغيرة. توجد طرق أخرى للتجانس، مثل تجانس الأغشية، لكنها غير عملية حاليًا لمعظم التطبيقات التجارية [124]. أشار كوستا وآخرون [125] إلى أن التجانس، خاصة عند استخدام قوى ميكانيكية شديدة، يمكن أن يؤثر على جزيئات المستحلب أو الهياكل فوق الجزيئية. غالبًا ما يتم تجاهل التأثير المشترك لدرجة الحرارة والقص على المستحلبات في أبحاث المستحلبات. على سبيل المثال، يمكن أن تؤدي الضغوط العالية إلى تغيير التركيب الثلاثي للبروتينات الكروية، مما يؤدي إلى تفكك البروتين حتى عندما تظل درجة حرارة المنتج أقل من درجة حرارة تغيير البروتين، مما قد يؤدي إلى تجمع البروتين. تعتبر ظروف التجانس، بما في ذلك نوع المعدات ومدخلات الطاقة، مهمة أيضًا لأنها تحدد توزيع حجم القطرات المحدد، والذي يؤثر مباشرة على قدرة المستحلب على مقاومة الأكسدة بسبب التغيرات في المساحة السطحية الكلية [126،127]. من حيث المبدأ، يجب أن تعزز القطرات الأصغر، وبالتالي مساحة الواجهة بين الزيت والماء الأكبر، أكسدة الدهون. بينما تم ملاحظة هذا التأثير غالبًا تجريبيًا، كانت هناك تقارير متضاربة، ربما ناتجة عن التحديات المتعلقة بتغيير حجم القطرات دون التأثير على خصائص المستحلب الأخرى [4]. أظهرت عدة دراسات، وخاصة من مجموعة C. Jacobsen، أن ظروف التجانس يمكن أن تؤثر على أكسدة الدهون في أنواع مختلفة من المستحلبات التي تحتوي على زيت السمك [128-130]. قام هورن وآخرون [128] بدراسة تأثير ضغوط ودرجات حرارة التجانس المختلفة على السمك.

(حلقات البوليمر الحيوي، المسام)، مما يثير الشكوك حول ما إذا كانت هذه المعلمة تلعب دورًا حاسمًا في أكسدة المستحلبات.

3.2. اتجاهات جديدة في مستحلبات الطعام

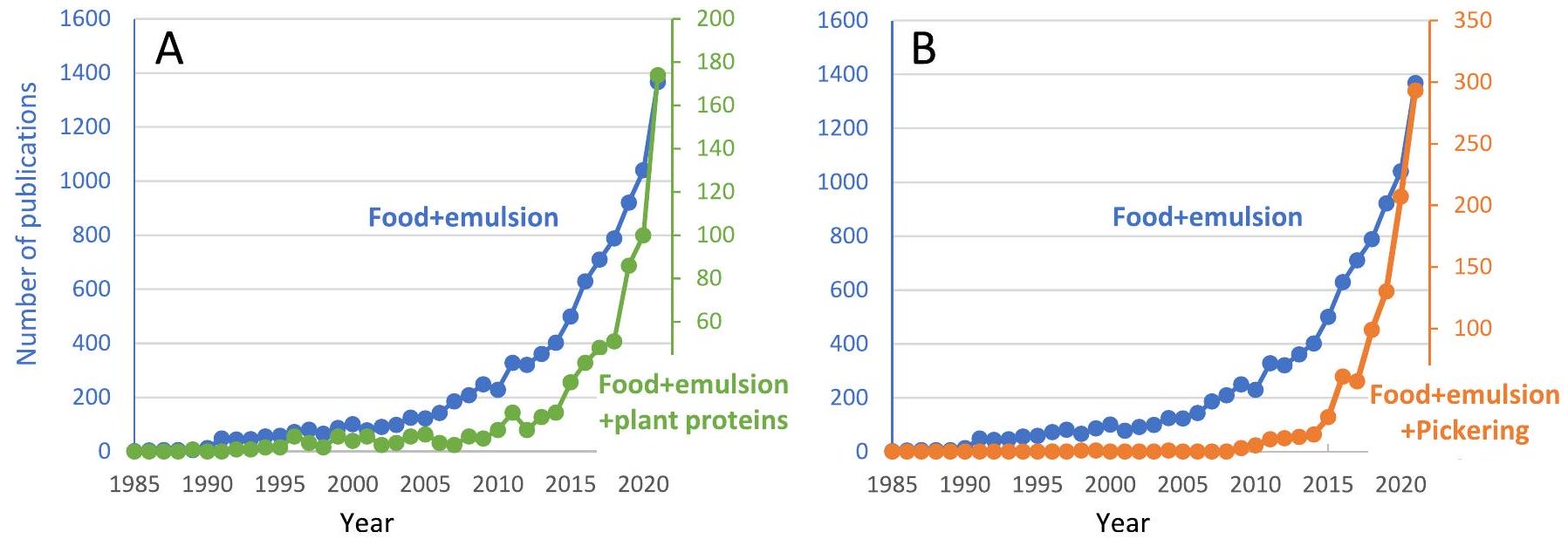

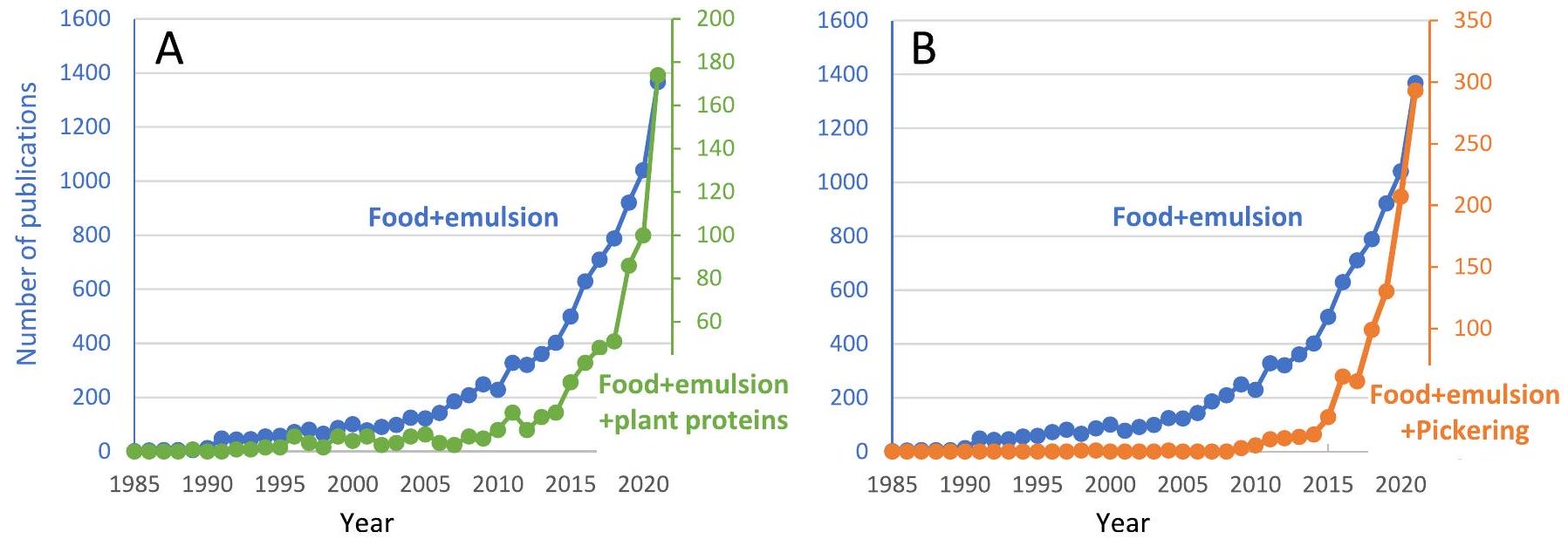

المستحلبات (الشكل 2). قبل عشرين عامًا، كانت هذه النسب حوالي

3.2.1. المستحلبات القائمة على بروتينات النباتات

3.2.2. مستحلبات بيكيرينغ

هيكل مختلف تمامًا، يفتقر إلى الجزيئات السطحية. أشارت النتائج إلى أن جزيئات بيكرينغ لم تمنع، بحد ذاتها، أكسدة الدهون مقارنةً بالمستحلبات المدعومة بالكازينيت، مما يشير إلى أن هذه الجزيئات لم تحفز تأثير حاجز فيزيائي عند السطح. ومع ذلك، أظهر المستحلب بيكرينغ استقرارًا أكسديًا أعلى مقارنةً بمستحلب التحكم الذي يحتوي على دهون ذات نقطة انصهار عالية في نواة القطيرات. تم نسب ذلك إلى تبلور الدهون داخل القطيرات في النظام الأخير، مما طرد الأحماض الدهنية المتعددة غير المشبعة القابلة للتغيير من داخل القطيرات إلى السطح، مما يسهل اتصالها بالعوامل المؤكسدة في المرحلة المائية. استكشف باحثون آخرون أيضًا استخدام جزيئات مختلفة قائمة على الدهون لتثبيت مستحلبات بيكرينغ [165]. وأبرزوا أهمية نوع الدهون المستخدمة لتشكيل الجزيئات في التأثير على أكسدة نواة قطيرات الزيت. على سبيل المثال، أظهرت المستحلبات بيكرينغ المصنوعة من جزيئات التريميستين أو زيت الزيتون مقاومة أكبر لأكسدة الدهون مقارنةً بمستحلب مدعوم بالبروتين التقليدي، بينما لم تظهر تلك المصنوعة من جزيئات زيت النخيل ميزة واضحة. من المثير للاهتمام، أن التأثير الوقائي للجزيئات السابقة لوحظ فقط عندما كانت موجودة أثناء تجانس المستحلب، وليس عند إضافتها بعد الاستحلاب، وهو تحكم مهم لنسب التأثير الوقائي للجزيئات إلى موضعها السطحي. علاوة على ذلك، لم يبدو أن الحالة الفيزيائية (بلورية مقابل سائلة) لمادة الدهون داخل الجزيئات كانت عاملًا مهيمنًا يؤثر على التأثير الوقائي لطبقة الجزيئات [165].

3.3. التوازن بين المستحلبات الممتصة/غير الممتصة

النشاط المضاد للأكسدة في المستحلبات الغذائية.

طريقة إضافة المضاد للأكسدة أثناء تحضير المستحلبات الغذائية مهمة أيضًا [167-169]. على سبيل المثال، فإن إضافة

تشارك في تسريع أكسدة القطرات المحيطة خلال خطوة الانتشار. على العكس، في حالة الدهون المحبة للدهون جدًا (مثل TAG-OOH، إلخ)، قد يشك المرء في أن انتشارها المحتمل سيكون مقيدًا، مما سيحد من تأثير المستحلبات غير الممتصة ونشاط المحفزات للأكسدة بين القطرات في المرحلة المبكرة من الأكسدة [27،98]. أخيرًا، تعتبر الهيدروبيروكسيدات الناتجة عن الأحماض الدهنية الحرة (FFA-OOH) أكثر نشاطًا سطحيًا من نظائرها التي تتكون على الدهون ذات الوزن الجزيئي الأعلى (TAGs، ثنائي الجليسريدات، إلخ) وأكثر استقرارًا من جذورها (FFA-OO•)، التي لها عمر نصف محدود، مما يجعلها مرشحًا جادًا في نشاط المحفزات للأكسدة بين القطرات [100]. ومع ذلك، ليس من الواضح ما إذا كان يمكن تحقيق مثل هذه الميكلية بواسطة FFAOOH وحدها أو ما إذا كان سيكون من الضروري وجود فائض من المستحلبات غير الممتصة (تكوين ميكلي مشترك).

زادت جزيئات مضادات الأكسدة مثل التوكوفيرولات في المنطقة الواجهة بسرعة مع زيادة تركيز السطحي [181،182]. تسلط هذه النتائج، إلى جانب العديد من النتائج الأخرى [101،173،183،184]، الضوء على دور الميسيلات في فعالية مضادات الأكسدة. وفقًا للأدبيات، بالنسبة لأكثر مضادات الأكسدة المحبة للدهون، فإن تكوين الميسيلات من شأنه تعزيز فعاليتها من خلال تحسين انتشارها و/أو تركيزها في المنطقة الواجهة، مما يعني أيضًا أن الشكل المؤكسد عند واجهة قطرات الدهون يمكن أن يتم استبداله بسرعة أكبر. بالنسبة لمضادات الأكسدة ذات القطبية المتوسطة والطبيعة الأمفيفيلية، فإن تكوين الميسيلات سيلجأ إلى تقليل تأثيرها، على الأرجح من خلال تقليل تركيزها عند واجهة الزيت والماء (“تأثير التخفيف”). بالنسبة لمضادات الأكسدة القابلة للذوبان في الماء بشكل كبير، لا يبدو أن هناك أي اتجاه محدد، على الأرجح لأن التأثير على توزيع مضادات الأكسدة سيكون أقل أهمية من التأثيرات المؤكسدة بين القطرات الناتجة عن الدهون والمعادن.

4. حساسية المستحلبات نفسها للأكسدة

4.1. مواد خافضة للتوتر السطحي ذات الوزن الجزيئي المنخفض

الكميات (

4.2. الفوسفوليبيدات

المستحلبات حسّنت من الاستقرار الأكسيدي لـ

تشمل المنتجات الوسيطة التي تتشكل في مسار التفاعل هذا استرات دهنية كيتونية إبوكسي، وإبوكسي ألكينال، وهيدروكسي ألكينال [235،239]. تم توثيق أنماط وسرعة أكسدة الفوسفوليبيدات بشكل كبير عند التعامل مع أنظمة ليبوسوم للغذاء أو التطبيقات الصيدلانية أو التجميلية. يتأثر الاستقرار الأكسيدي لليبوسومات بشكل كبير بحجمها وتركيبها الجزيئي بالإضافة إلى التركيب الجزيئي للوسط المحيط بها [240]. على سبيل المثال، بالنسبة للفوسفوليبيدات البحرية، فإن هذا التحول سريع جدًا لدرجة أن التكوين المعتاد لهيدروبيروكسايد الدهون والألدهيدات الذي يتم تقييمه من خلال قياس قيمة البيروكسيد (PV)، قيمة الأنيزيدين (AV) أو المواد الثيوباربيتورية (TBARS) لا يمكن اكتشافه، مما قد يؤدي إلى استنتاج خاطئ بعدم حدوث أكسدة للدهون [241]. فيما يتعلق بالمستحلبات التي يتم تثبيتها بواسطة الليسيثينات، على حد علمنا، لا توجد أبحاث حيث تم مقارنة حركيات أكسدة الفوسفوليبيدات مقابل تلك الخاصة بـ TAGs. ومع ذلك، في مثل هذه المستحلبات، حيث تقع الفوسفوليبيدات إما في المنطقة الواجهة أو كتركيبات غروانية في المرحلة المستمرة، يمكن افتراض أنه، مقارنة بقطرات الدهون، ستكون الفوسفوليبيدات أكثر اتصالًا بالمؤكسدات ويمكن أن تتأكسد بشكل أسرع. بالمثل، يمكن الإشارة إلى الدراسات المختلفة التي أجريت على دراسة الاستقرار الأكسيدي في نظام اللحم النموذجي. قام إجن [242] بتقييم تأثير TAGs والفوسفوليبيدات على تطور الرائحة باستخدام ألياف عضلية خالية من الدهون بالاشتراك مع TAGs أو فوسفوليبيدات مضافة. أظهرت النتائج أن كل من TAGs والفوسفوليبيدات تساهم في تطور الرائحة، على الرغم من أن الفوسفوليبيدات كانت الأولى في الأكسدة. لاحقًا، أظهرت نفس مجموعة البحث أن PE و PC كانا حساسين بشكل خاص للأكسدة في اللحم المجمد [243]. أكد آخرون هذه الملاحظة ووجدوا أن

4.3. البروتينات

كشفت عن توزيع غير متجانس لأكسدة البروتين عند الواجهة مما يشير إلى حبيبات البروتين الدهني التي توجد عادة في صفار البيض. أخيرًا، في غياب التوكوفيرولات (زيت مُنزع)، تم تعزيز أكسدة البروتين سواء عند الواجهة أو في المرحلة المستمرة. وقد تم عزو هذه الزيادة في أكسدة البروتين عند إزالة التوكوفيرول إلى نقل الجذور الحرة الدهنية من قطرات الزيت إلى الواجهة والمرحلة المستمرة. كما قام المؤلفون بتقييم تأثير حمض الأسكوربيك على أكسدة الدهون والبروتين. في وجود التوكوفيرولات، أظهر حمض الأسكوربيك تأثيرًا مضادًا للأكسدة تجاه الدهون، بينما في غياب التوكوفيرولات، تصرف كعامل مؤكسد. ومع ذلك، أظهرت دراسات أخرى أن حمض الأسكوربيك يعمل كعامل محفز قوي لأكسدة الدهون في المايونيز المُعد بمزيج من زيت اللفت وزيت السمك، الذي يحتوي على التوكوفيرولات. فيما يتعلق بأكسدة البروتين، عمل حمض الأسكوربيك كعامل مؤكسد للبروتينات الممتصة عند الواجهة وكذلك لتلك الموجودة في المرحلة المستمرة. ومن المثير للاهتمام، تم الإبلاغ عن سلوكيات متناقضة مع مضادات الأكسدة الأخرى فيما يتعلق بأكسدة الدهون أو البروتين.

5. مضادات أكسدة جديدة من الأنظمة النموذجية إلى تطبيقات الطعام الحقيقية

مما دفع إلى إعادة تقييم المفارقة القطبية وإدخال مفاهيم ونظريات جديدة [278]. على سبيل المثال، في الزيت السائب، كما تم شرحه سابقًا (القسم 2.4.2)، تم إثبات أن الموقع الحرج للأكسدة ليس هو واجهة الهواء والزيت، كما تم اقتراحه سابقًا في المفارقة القطبية. بدلاً من ذلك، تحدث الأكسدة في الكولودات المرتبطة التي تتكون من آثار من الماء وجزيئات نشطة سطحياً مثل الفوسفوليبيدات. في نفس الفترة، تم إثبات أنه في المستحلبات O/W، ينطبق علاقة غير خطية بين الكارهة للماء وقدرة مضادات الأكسدة [279]. تم دراسة هذا التأثير، المعروف باسم تأثير القطع، بشكل موسع وتم تأكيده، كما هو موضح في ما يلي (القسم 5.1).

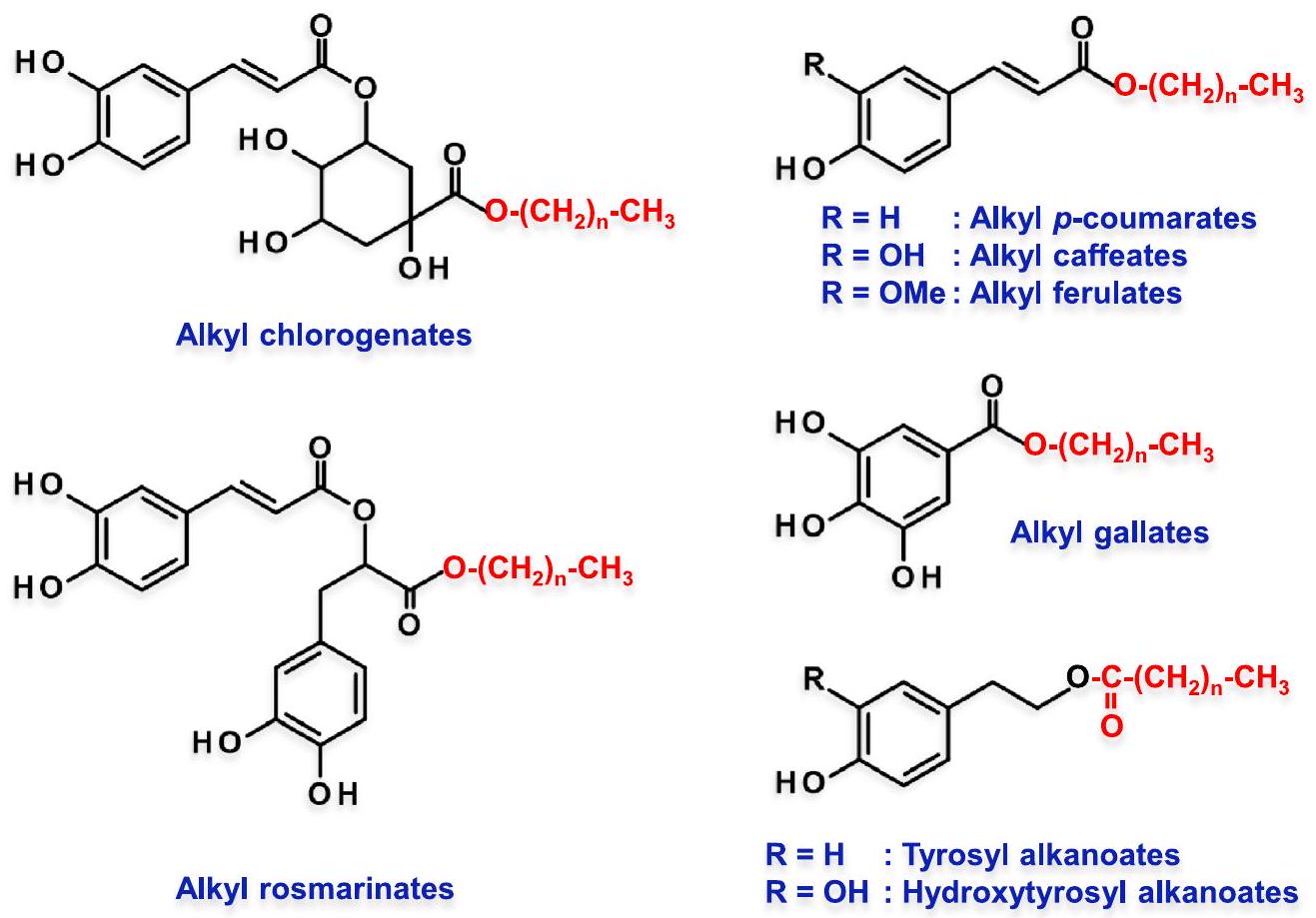

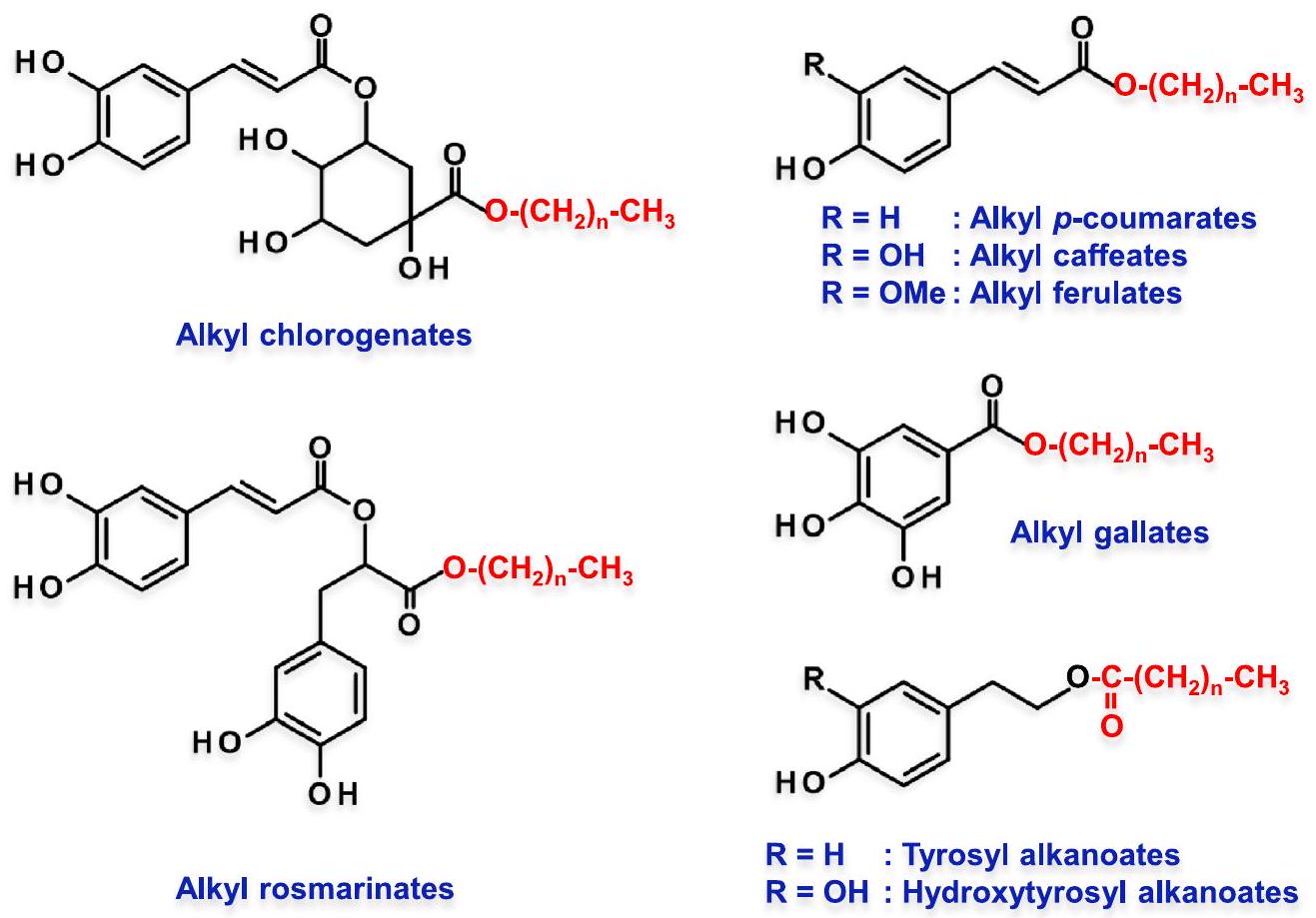

5.1. الفينوليبيدات وتأثير القطع

أو الهيدروكسيل الأولي مع الأحماض الكربوكسيلية الأليفاتية على التوالي. وبالتالي، من خلال الحفاظ على الهيدروكسيل الفينولي، احتفظت الجزيئات الناتجة، التي تُسمى “الفينوليبيدات”، بجميع تفاعليتها مع الجذور الحرة. تعتبر زيادة المحبة للدهون عن طريق الاسترification، التي تُجرى عادةً في ظروف قاسية مع محفزات حمضية قوية (حمض الهيدروكلوريك، حمض الكبريتيك، حمض بارا-تولوين السلفوني، راتنجات الأحماض السلفونية)، فعالة جدًا وكميّة، ويمكن دفعها إلى الاكتمال من خلال التجفيف المستمر للوسط عندما يتم إنتاج الماء. على العكس من ذلك، تسمح الإنزيمات بتخليق الفينوليبيدات في ظروف أكثر اعتدالًا مع اختيار أفضل وأقل تفاعلات جانبية. ومع ذلك، فإن التحفيز الإنزيمي غالبًا ما يكون أبطأ بكثير، وقد يكون عرضة لظواهر التثبيط، وكما تم وصفه مؤخرًا في عدة مراجعات، يتطلب ضبطًا دقيقًا للعديد من المعلمات ليكون فعالًا [283-285].

بروبيل؛ C8، أوكتيل؛ C12، أوكتادسيل) (الشكل 3) في مستحلبات زيت الزيتون أو زيت الذرة في الماء بنسب مختلفة من الزيت: الماء (

أطوال السلسلة الحرجة (CCL) ضمن سلسلة الفينوليد.

| فينوليبدات | سلاسل الألكيل المختبرة

|

نظام الدهون | مستحلب | CCL

|

ملاحظات | مرجع |

| ألكانات هيدروكسي تيروسيل | 0، 2، 4، 8، 12 | مستحلبات السمك O/W | ليسيثين | ٨ | [292] | |

| روسمارينات الألكيل |

|

مستحلب تونغ O/W | بريج 35 | ٨ | [293] | |

| روسمارينات الألكيل | 0، 4، 8، 12، 18، 20 | مستحلب فول الصويا O/W | توين 20 | ٤ | [180] | |

| كومارات الألكيل | 1، 4، 8، 12، 16، 18، 20 | مستحلب تونغ O/W | بريج 35 | 12 | نشاط مضاد للأكسدة ضعيف جداً لجميع المركبات الفينولية | [294] |

| فوريلات الألكيل |

|

مستحلب تونغ O/W | بريج 35 | ٤-١٢ | [294] | |

|

|

حليب مدعم بزيت السمك | – | 1 | أثر مؤكسد لـ C12 و C8؛ C16 و C20 شبه غير نشط | [295] | |

|

|

مستحلب تونغ O/W | بريج 35 | ٨ | [294] | ||

| كافئات الألكيل | 0، 1، 4، 8، 12، 18 | مايونيز مدعم بزيت السمك | – | ٤-١٢ | مايونيز قائم على زيت اللفت | |

|

|

حليب مدعم بزيت السمك | – | 1-4 | [296] | ||

| بروتوكاتشوات الألكيل | 1، 2، 4، 6، 8، 10، 12، 14، 16، 18 | مستحلب تونغ O/W | بريج 35 | 2-4 | عملت C2-C6 ككاسرات سلسلة، بينما عملت C12-C20 كمؤخرات. | [297] |

| الألكيل ريسورسينولات من نخالة الجاودار الطبيعية | 17، 19، 21، 23، 25 | مستحلب الطحالب O/W | بريج L23 | 21 | كانت جميع الألكيل ريسورسينولات أكثر فعالية من الأورسينول | [298] |

| غالات الألكيل | 0، 3، 8، 12، 16 | مستحلب مجفف بالرش (بروتين مصل اللبن + كازينات + زيوت عباد الشمس والأسماك) | – | ٨ | تأثير قطع طفيف جداً. جالات الهيدروفوبية (

|

[299] |

5.2. الببتيدات (على سبيل المثال، المشتقة من المنتجات الثانوية)

5.2.1. النهج من الأعلى إلى الأسفل للحصول على ببتيدات مضادة للأكسدة

5.2.2. النهج التصاعدي للحصول على ببتيدات مضادة للأكسدة

أظهرت الدراسة نقص تقنيات الفحص الموثوقة لاختبار خلب المعادن للببتيدات الاصطناعية والحاجة إلى تقنيات متقدمة جديدة. من ناحية أخرى، تم اعتبار معلمات أخرى مهمة لنشاط خلب المعادن مثل النقطة المعزولة والشحنة الصافية عند pH 7.0 لاختيار الببتيدات الخالبة للمعادن. أظهرت النتائج أن جميع الببتيدات قدمت استقرارًا أكسديًا أفضل أو مشابهًا مقارنةً بالإيمولسيون الضابطة بدون مضادات الأكسدة وبالتالي منعت أكسدة الدهون في نظام إيمولسيون نموذجي. بشكل خاص، كانت الببتيدات المشحونة تؤدي بشكل أفضل من الببتيدات المحايدة، وكان طول الببتيدات النشطة يتراوح بين 6 و 14 حمضًا أمينيًا. أظهرت هذه الدراسة إمكانيات المعلوماتية الحيوية والبروتيوميات في تحديد الببتيدات الطبيعية المستدامة الغنية بمضادات الأكسدة الموجودة في البروتينات الأم. تتيح المنهجية استهداف الببتيدات بدقة من خلال التحلل المائي الإنزيمي المصمم، باستخدام خصوصية البروتياز وتحليل تسلسل المعلوماتية الحيوية.

5.2.3. فحص الببتيدات الخالبة للمعادن

(IMAC). تعتبر تقنية SPR تقنية بصرية لتحديد ثوابت التفكك (

5.3. جزيئات بيكرينغ المحملة بمضادات الأكسدة: جزيئات مصممة عمدًا (من الأسفل إلى الأعلى) مقابل الهياكل الطبيعية (من الأعلى إلى الأسفل)

(DMSNs)، التي تعمل كحاملات نانوية لمضادات الأكسدة المحبة للماء أو الكارهة للماء (تم إثبات ذلك بالنسبة للإيبيغالوكتشين غالاتي والريسفيراترول) وكمنظمات بيكرينغ [335]. على الرغم من أن هذا النظام تم اختباره فقط لتثبيت زيت النكهة (وليس زيت غني بالأحماض الدهنية المتعددة غير المشبعة)، إلا أن الجسيمات احتفظت بشكل فعال بمضاد الأكسدة المستهدف داخل هيكلها الداخلي وحمت بشكل كبير السيترال من الأكسدة. لقد أثبتت هذه التصاميم المتقدمة الهرمية للجسيمات البيكرينغ ثنائية الوظيفة مفهوم الخزانات المضادة للأكسدة على الواجهة وتقدم وعدًا لتعزيز فعالية مضادات الأكسدة الطبيعية. ومع ذلك، فإن أحد العيوب الرئيسية التي قد تحد من تطبيقها على نطاق واسع هو التعقيد والتكلفة لمثل هذه الاستراتيجية، والتي قد لا تتماشى مع الاتجاه الحالي نحو أنظمة الغذاء الطبيعية، ذات الملصقات النظيفة، والمعالجة بشكل ضئيل. قد تتضمن نهجًا بديلاً، مع الاستمرار في استخدام مفهوم الجسيمات البيكرينغ المحملة بمضادات الأكسدة، الاستفادة من المحتوى الطبيعي لمضادات الأكسدة في الجسيمات الموجودة بشكل طبيعي (أي، اعتماد نهج “من الأعلى إلى الأسفل” بدلاً من “من الأسفل إلى الأعلى”، كما في الأمثلة السابقة)، مثل الجوانب الجانبية للمنتجات الغذائية والمنتجات المستندة إلى البيولوجيا. بينما سيكون مستوى التحكم في التركيب والبنية لهذه الجسيمات بالضرورة أقل من تلك الجسيمات المركبة المصممة خصيصًا، فإن لديها إمكانات كبيرة من حيث الاستدامة والطبيعية والاحتفاظ بالمضادات الأكسدة على الواجهة [159]. أحد الأمثلة على هذه الاستراتيجية تتضمن المستحلبات البيكرينغ المستقرة بجسيمات الأرز الأحمر المطحون التي تحتوي على الأنثوسيانين [336]. أظهرت هذه الدراسة أن هذه الجسيمات الغنية بالبوليفينول قدمت حماية أفضل لقطرات الزيت المستحلب ضد الأكسدة مقارنة بالمستحلبات المستقرة بالنشا من الأرز الأبيض والزيت السائب. أظهرت دراسة حديثة أخرى تركزت على تحضير المستحلبات البيكرينغ باستخدام جسيمات نباتية متنوعة، أن المستحلبات المستقرة بجسيمات شاي الماتشا وأوراق السبانخ كانت مستقرة للغاية ضد أكسدة الدهون، على عكس المستحلبات المرجعية المستقرة بواسطة المستحلبات التقليدية [337]. من المحتمل أن يُعزى هذا التأثير الوقائي إلى وجود مضادات الأكسدة الذاتية في هذه الفئات، مثل الفينولات التي تلتقط الجذور الحرة والأحماض العضوية المخلبية، على التوالي. يبدو أن استخدام مثل هذه الجسيمات الطبيعية هو نهج واعد لتثبيت المستحلبات ذات الملصقات النظيفة بشكل مادي وأكسدي. نظرًا للوجود الواسع والتنوع لمضادات الأكسدة الفينولية في المواد النباتية المتوافقة مع الغذاء، فلا شك أن هناك العديد من المصادر المحتملة لجسيمات البيكرينغ لاستكشافها.

5.4. نحو مكونات نظيفة و متعددة الوظائف

نظرة عامة على المكونات (المحتملة) ذات العلامة النظيفة التي تمتلك نشاطًا مضادًا للأكسدة في مستحلبات الطعام O/W.

| مستحلب الطعام | مكون حيوي | المكونات/ الآليات المقترحة لمضادات الأكسدة | مرجع |

| مايونيز | بقايا التفاح | الفينولات | [342] |

| مسحوق الزنجبيل | غير محدد | [343] | |

| مستخلص بذور العنب | التخلص من الجذور الحرة بواسطة الفينولات | ||

| خل العنب والتفاح | الفينولات | [345] | |

| خل البلسميك | ميلانويدينات | [346] | |

| مستخلص قشر التفاح | الفينولات | [347] | |

| مستخلصات الطحالب البنية | الفينولات | [348] | |

| جذر الشمندر | الفينولات، البيتالين | [349] | |

| قشر الشمندر | الفينولات، البيتالين | [٣٥٠] | |

| منتج ثانوي من الطماطم | كاروتينات | [351] | |

| مستخلصات الذرة الأرجوانية | الأنثوسيانين | [352] | |

| مستخلصات بذور الخيار | الفينولات | [353] | |

| مايونيز نباتي | نفايات معصرة الزيتون | الفينولات | [354] |

| دقيق الفاكهة | الفينولات | [355] | |

| خل الزيتون | الفينولات | [356] | |

| مستخلص كعكة الكمون | الفينولات، التخلص من الجذور الحرة | [357] | |

| نموذج مستحلب O/W | نسب القهوة المحمصة | تقسيم MRPs | [358] |

| خل ورق الزيتون | الفينولات، أوليوروبين | [359] | |

| مستخلصات نخالة الأرز | غير محدد | [360] |

المصدر من النفايات أو الجوانب الجانبية. بالنسبة لمعظم المكونات في الجدول 2، تم نسب نشاطها المضاد للأكسدة إلى وجود الفينولات في المرحلة المائية من مستحلبات الطعام، ولكن دون إقامة رابط آلي سببي واضح.

ضمان سلامة الغذاء، بما في ذلك المنتجات الثانوية المستخدمة كمكونات غذائية. ومع ذلك، عندما تعمل هذه المنتجات الثانوية كإضافات طبيعية، يصبح الامتثال لائحة الأغذية الجديدة (اللائحة الأوروبية رقم 2015/2283) إلزاميًا. تحدد هذه اللائحة فئات الأغذية الجديدة التي تنشأ من النباتات والحيوانات والميكروبات وتقنيات الإنتاج الجديدة. تتطلب هذه الأغذية الحصول على إذن وإدراجها في قائمة الأغذية الجديدة المصرح بها التي تديرها الهيئة الأوروبية لسلامة الغذاء (EFSA). يجب الإشارة إلى أن عدم وجود تعريف واضح لنفايات الطعام والمنتجات الثانوية يشكل تحديًا، مما يعيق التقييم الدقيق ويعوق التدابير لمعالجة فقدان الطعام والنفايات. لذلك، يبدو أن التعريفات الواضحة لهذه المصطلحات ضرورية للبحوث المستقبلية وبرامج الأعمال لتعزيز الابتكار في نظام الاقتصاد الدائري. توحيد السياسات، وتقليل الأعباء الإدارية، وإرساء تنظيمات مستقرة هي أمور حيوية لتعزيز الاستثمارات وتسهيل تحويل النفايات إلى موارد قيمة. علاوة على ذلك، يعد الكودكس أليمنتاريوس، وهو مبادرة من منظمة الأغذية والزراعة (FAO) ومنظمة الصحة العالمية (WHO)، مرجعًا عالميًا لسلامة الغذاء، حيث يضع معايير وإرشادات دولية. غالبًا ما تتضمن هذه الإرشادات حدودًا مسموح بها للملوثات والإضافات والمغذيات، والتي تعتبر ضرورية لتطوير تنظيمات سلامة غذاء سليمة. تحدد الهيئات التنظيمية مثل إدارة الغذاء والدواء (FDA) في الولايات المتحدة والهيئة الأوروبية لسلامة الغذاء (EFSA) مستويات الاستهلاك اليومي المقبول (ADI) للإضافات لحماية المستهلكين من المواد الضارة. ومع ذلك، لا تزال التحديات قائمة في تقييم ملاءمة وسلامة المنتجات الثانوية بسبب غياب حدود قانونية محددة. لذلك، غالبًا ما تعتمد القيم المرجعية لتقييم المنتجات الثانوية في هذا الصدد على الحدود المحددة للمواد الأصلية أو المصفوفات المماثلة، مما يؤدي إلى تعقيد تفسير النتائج وضمان سلامة المستهلك.

6. الاستنتاجات والرؤية المستقبلية

التقدمات المنهجية الرائدة التي هي قيد التطوير النشط، سيكون إنشاء ممارسات موحدة محورياً في معالجة تعقيد تفاعلات أكسدة الدهون. هذا التوافق في المنهجيات عبر الجهود البحثية لن يعزز فقط القابلية للمقارنة ولكن سيسهل أيضاً فهمًا أكثر شمولية لآليات الأكسدة. في الوقت نفسه، فإن تطور تقنيات النمذجة يظهر كحدود حاسمة. سيكون تحسين وتطوير هذه النماذج ضروريًا في التنبؤ ومحاكاة سلوك أكسدة الدهون داخل هذه الأنظمة، مما يساعد في تصميم التجارب وكشف العلاقات المعقدة بين العوامل المعنية.

مصادر التمويل

بيان مساهمة المؤلفين وفقاً لنظام CRediT

إعلان عن تضارب المصالح

References

[2] Cosgrove JP, Church DF, Pryor WA. The kinetics of the autoxidation of polyunsaturated fatty acids. Lipids. 1987;22(5):299-304. https://doi.org/ 10.1007/BF02533996.

[3] McClements DJ, Decker EA. Lipid oxidation in oil-in-water emulsions: impact of molecular environment on chemical reactions in heterogeneous food systems.

[4] Berton-Carabin CC, Ropers MH, Genot C. Lipid oxidation in oil-in-water emulsions: involvement of the interfacial layer. Comprehen Rev Food Sci Food Safet 2014;13(5):945-77. https://doi.org/10.1111/1541-4337.12097.

[5] ten Klooster S, Boerkamp V, Lazaridi E, Yang S, Takeuchi M, Berton-Carabin C, et al. Lipid oxidation in food emulsions: Analytical challenges and recent developments. In: Bravo-Diaz C, editor. Lipid oxidation in food and biological systems: A physical chemistry perspective. Cham: Springer International Publishing; 2022. p. 3-29. https://doi.org/10.1007/978-3-030-87222-9_1.

[6] Barriuso B, Astiasarán I, Ansorena D. A review of analytical methods measuring lipid oxidation status in foods: a challenging task. Eur Food Res Technol 2013; 236(1):1-15. https://doi.org/10.1007/s00217-012-1866-9.

[7] Laguerre M, Lecomte J, Villeneuve P. Evaluation of the ability of antioxidants to counteract lipid oxidation: existing methods, new trends and challenges. Prog Lipid Res 2007;46(5):244-82. https://doi.org/10.1016/j.plipres.2007.05.002.

[8] Xia W, Budge SM. Techniques for the analysis of minor lipid oxidation products derived from Triacylglycerols: epoxides, alcohols, and ketones. Compr Rev Food Sci Food Saf 2017;16(4):735-58. https://doi.org/10.1111/1541-4337.12276.

[9] Jacobsen C, García-Moreno PJ, Yesiltas B, Sørensen A-DM. Chapter 9 – lipid oxidation and traditional methods for evaluation. In: García-Moreno PJ, et al., editors. Omega-3 delivery systems. Academic Press; 2021. p. 183-200. https:// doi.org/10.1016/B978-0-12-821391-9.00009-0.

[10] McClements DJ. Food emulsions: Principles, practices, and techniques. 3rd edition ed. Boca Raton: CRC Press; 2015. https://doi.org/10.1201/b18868.

[11] Food emulsifiers and their applications. 3rd edition ed. Springer Cham; 2019. p. 522. https://doi.org/10.1007/978-3-030-29187-7.

[12] Drusch S, Klost M, Kieserling H. Current knowledge on the interfacial behaviour limits our understanding of plant protein functionality in emulsions. Curr Opin Colloid Interface Sci 2021;56:101503. https://doi.org/10.1016/j. cocis.2021.101503.

[13] Dickinson E. Proteins at interfaces and in emulsions stability, rheology and interactions. J Chem Soc Faraday Trans 1998;94(12):1657-69. https://doi.org/ 10.1039/A801167B.

[14] Dickinson E. Use of nanoparticles and microparticles in the formation and stabilization of food emulsions. Trends Food Sci Technol 2012;24(1):4-12. https://doi.org/10.1016/j.tifs.2011.09.006.

[15] Berton-Carabin CC, Schroen K. Pickering emulsions for food applications: background, trends, and challenges. Annu Rev Food Sci Technol 2015;6:263-97. https://doi.org/10.1146/annurev-food-081114-110822.

[16] Murray BS. Pickering emulsions for food and drinks. Curr Opin Food Sci 2019;27: 57-63. https://doi.org/10.1016/j.cofs.2019.05.004.

[17] Pickering SU. CXCVI.-emulsions. J Chem Soc Trans 1907;91(0):2001-21. https://doi.org/10.1039/CT9079102001.

[18] Tcholakova S, Denkov N, Lips A. Comparison of solid particles, globular proteins and surfactants as emulsifiers. Phys Chem Chem Phys 2008;10(12):1608-27. https://doi.org/10.1039/B715933C.

[19] Berton-Carabin CC, Sagis L, Schroen K. Formation, structure, and functionality of interfacial layers in food emulsions. Annu Rev Food Sci Technol 2018;9:551-87. https://doi.org/10.1146/annurev-food-030117-012405.

[20] Bos MA, van Vliet T. Interfacial rheological properties of adsorbed protein layers and surfactants: a review. Adv Colloid Interface Sci 2001;91(3):437-71. https:// doi.org/10.1016/S0001-8686(00)00077-4.

[21] Murray BS. Rheological properties of protein films. Curr Opin Colloid Interface Sci 2011;16(1):27-35. https://doi.org/10.1016/j.cocis.2010.06.005.

[22] Hinderink EB, Sagis L, Schroën K, Berton-Carabin CC. Behavior of plant-dairy protein blends at air-water and oil-water interfaces. Colloids Surf B Biointerfaces 2020;192:111015. https://doi.org/10.1016/j.colsurfb.2020.111015.

[23] Chevalier Y, Bolzinger M-A. Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf A Physicochem Eng Asp 2013;439:23-34. https://doi.org/10.1016/j.colsurfa.2013.02.054.

[24] ten Klooster S, Takeuchi M, Schroën K, Tuinier R, Joosten R, Friedrich H, et al. Tiny, yet impactful: detection and oxidative stability of very small oil droplets in surfactant-stabilized emulsions. J Colloid Interface Sci 2023. https://doi.org/ 10.1016/j.jcis.2023.09.005.

[25] Guzey D, McClements DJ. Formation, stability and properties of multilayer emulsions for application in the food industry. Adv Colloid Interface Sci 2006; 128-130:227-48. https://doi.org/10.1016/j.cis.2006.11.021.

[26] Samtlebe M, Yucel U, Weiss J, Coupland JN. Stability of solid lipid nanoparticles in the presence of liquid oil emulsions. J Am Oil Chem Soc 2012;89(4):609-17. https://doi.org/10.1007/s11746-011-1944-3.

[27] Klooster ST, Schroën K, Berton-Carabin C. Lipid oxidation products in model food emulsions: do they stay in or leave droplets, that’s the question. Food Chem 2023; 405:134992. https://doi.org/10.1016/j.foodchem.2022.134992.

[28] McClements D, Dungan S, German J, Kinsella J. Oil exchange between oil-inwater emulsion droplets stabilised with a non-ionic surfactant. Food Hydrocoll 1992;6(5):415-22. https://doi.org/10.1016/S0268-005X(09)80027-1.

[29] Schaich KM. Lipid oxidation: theoretical aspects. In: Bailey’s Industrial Oil and Fat Products; 2005. https://doi.org/10.1002/047167849X.bio067.

[30] Frankel EN. Chapter 1 – free radical oxidation. In: Frankel EN, editor. Lipid oxidation. 2nd ed. Woodhead Publishing; 2012. p. 15-24. https://doi.org/ 10.1533/9780857097927.15.

[31] Frankel EN. Lipid Oxidation. Elsevier; 2014.

[32] Kerr JA. Bond dissociation energies by kinetic methods. Chem Rev 1966;66(5): 465-500. https://doi.org/10.1021/cr60243a001.

[33] Frankel EN. Volatile lipid oxidation products. Prog Lipid Res 1983;22(1):1-33. https://doi.org/10.1016/0163-7827(83)90002-4.

[34] Schaich KM. Metals and lipid oxidation. Contemporary issues. Lipids. 1992;27(3): 209-18. https://doi.org/10.1007/BF02536181.

[35] Minotti G, Aust SD. Redox cycling of iron and lipid peroxidation. Lipids. 1992;27 (3):219-26. https://doi.org/10.1007/BF02536182.

[36] Mozuraityte R, Kristinova V, Rustad T, Storrø I. The role of iron in peroxidation of PUFA: effect of pH and chelators. Eur J Lipid Sci Technol 2016;118(4):658-68. https://doi.org/10.1002/ejlt.201400590.

[37] Mozuraityte R, Rustad T, Storrø I. The role of iron in peroxidation of polyunsaturated fatty acids in liposomes. J Agric Food Chem 2008;56(2):537-43. https://doi.org/10.1021/jf0716073.

[38] Ingold KU. Inhibition of the autoxidation of organic substances in the liquid phase. Chem Rev 1961;61(6):563-89. https://doi.org/10.1021/cr60214a002.

[39] Jacobsen C, Timm M, Meyer AS. Oxidation in fish oil enriched mayonnaise: ascorbic acid and low pH increase oxidative deterioration. J Agric Food Chem 2001;49(8):3947-56. https://doi.org/10.1021/jf001253e.

[40] Jacobsen C, Let MB, Nielsen NS, Meyer AS. Antioxidant strategies for preventing oxidative flavour deterioration of foods enriched with n-3 polyunsaturated lipids: a comparative evaluation. Trends Food Sci Technol 2008;19(2):76-93. https:// doi.org/10.1016/j.tifs.2007.08.001.

[41] Shahidi F, Ambigaipalan P. Phenolics and polyphenolics in foods, beverages and spices: antioxidant activity and health effects-A review. J Funct Foods 2015;18: 820-97. https://doi.org/10.1016/j.jff.2015.06.018.

[42] Quideau S, Deffieux D, Douat-Casassus C, Pouységu L. Plant polyphenols: chemical properties, biological activities, and synthesis. Angew Chem Int Ed 2011;50(3):586-621. https://doi.org/10.1002/anie.201000044.

[43] Jacobsen C, Hartvigsen K, Thomsen MK, Hansen LF, Lund P, Skibsted LH, et al. Lipid oxidation in fish oil enriched mayonnaise: calcium disodium ethylenediaminetetraacetate, but not gallic acid, strongly inhibited oxidative deterioration. J Agric Food Chem 2001;49(2):1009-19. https://doi.org/10.1021/ jf000729r.

[44] Gumus CE, Decker EA, McClements DJ. Impact of legume protein type and location on lipid oxidation in fish oil-in-water emulsions: lentil, pea, and faba bean proteins. Food Res Int 2017;100(Pt 2):175-85. https://doi.org/10.1016/j. foodres.2017.08.029.

[45] Berton C, M.H.L.N. Ropers, Guibert D, Solé VR, Genot C. Modifications of interfacial proteins in oil-in-water emulsions prior to and during lipid oxidation. J Agric Food Chem 2012;60(35):8659-71. https://doi.org/10.1021/jf300490w.

[46] Schaich KM. Lipid oxidation: new perspectives on an old reaction. In: Bailey’s Industrial Oil and Fat Products; 2020. p. 1-72. https://doi.org/10.1002/ 047167849X.bio067.pub2.

[47] Mubiru E, Shrestha K, Papastergiadis A, De Meulenaer B. Improved gas chromatography-flame ionization detector analytical method for the analysis of epoxy fatty acids. J Chromatogr A 2013;1318:217-25. https://doi.org/10.1016/j. chroma.2013.10.025.

[48] Marmesat S, Velasco J, Dobarganes MC. Quantitative determination of epoxy acids, keto acids and hydroxy acids formed in fats and oils at frying temperatures. J Chromatogr A 2008;1211(1):129-34. https://doi.org/10.1016/j. chroma.2008.09.077.

[49] Velasco J, Berdeaux O, Márquez-Ruiz G, Dobarganes MC. Sensitive and accurate quantitation of monoepoxy fatty acids in thermoxidized oils by gas-liquid chromatography. J Chromatogr A 2002;982(1):145-52. https://doi.org/ 10.1016/S0021-9673(02)01481-4.

[50] Velasco J, Marmesat S, Bordeaux O, Márquez-Ruiz G, Dobarganes C. Formation and evolution of Monoepoxy fatty acids in Thermoxidized olive and sunflower oils and quantitation in used frying oils from restaurants and fried-food outlets. J Agric Food Chem 2004;52(14):4438-43. https://doi.org/10.1021/jf030753f.

[51] Mubiru E, Shrestha K, Papastergiadis A, De Meulenaer B. Development and validation of a gas chromatography-flame ionization detection method for the determination of epoxy fatty acids in food matrices. J Agric Food Chem 2014;62 (13):2982-8. https://doi.org/10.1021/jf405664c.

[52] Grüneis V, Fruehwirth S, Zehl M, Ortner J, Schamann A, J.r. König, and M. Pignitter.. Simultaneous analysis of epoxidized and hydroperoxidized triacylglycerols in canola oil and margarine by LC-MS. J Agric Food Chem 2019; 67(36):10174-84. https://doi.org/10.1021/acs.jafc.9b03601.

[53] Fruehwirth S, Egger S, Flecker T, Ressler M, Firat N, Pignitter M. Acetone as indicator of lipid oxidation in stored margarine. Antioxidants. 2021;10(1):59. https://doi.org/10.3390/antiox10010059.

[54] Boerkamp VJ, Merkx DW, Wang J, Vincken J-P, Hennebelle M, van Duynhoven JP. Quantitative assessment of epoxide formation in oil and mayonnaise by 1H-13C HSQC NMR spectroscopy. Food Chem 2022;390:133145. https://doi.org/10.1016/j.foodchem.2022.133145.

[55] Steenhorst-Slikkerveer L, Louter A, Janssen H-G, Bauer-Plank C. Analysis of nonvolatile lipid oxidation products in vegetable oils by normal-phase highperformance liquid chromatography with mass spectrometric detection. J Am Oil Chem Soc 2000;77(8):837. https://doi.org/10.1007/s11746-000-0134-1.

[56] Morales A, Marmesat S, Ruiz-Méndez MV, Márquez-Ruiz G, Velasco J. Formation of oxidation products in edible vegetable oils analyzed as FAME derivatives by HPLC-UV-ELSD. Food Res Int 2014;62:1080-6. https://doi.org/10.1016/j. foodres.2014.05.063.

[57] Morales A, Dobarganes C, Márquez-Ruiz G, Velasco J. Quantitation of Hydroperoxy-, keto- and Hydroxy-dienes during oxidation of FAMEs from highlinoleic and high-oleic sunflower oils. J Am Oil Chem Soc 2010;87(11):1271-9. https://doi.org/10.1007/s11746-010-1624-8.

[58] Morales A, Marmesat S, Dobarganes MC, Márquez-Ruiz G, Velasco J. Quantitative analysis of hydroperoxy-, keto- and hydroxy-dienes in refined vegetable oils. J Chromatogr A 2012;1229:190-7. https://doi.org/10.1016/j. chroma.2012.01.039.

[59] Morales A, Marmesat S, Dobarganes MC, Márquez-Ruiz G, Velasco J. Formation of Hydroperoxy-, keto- and Hydroxy-dienes in FAME from oils: influence of temperature and addition of

[60] Emami S, Zhang Z, Taha AY. Quantitation of Oxylipins in fish and algae oil supplements using optimized hydrolysis procedures and ultra-high performance liquid chromatography coupled to tandem mass-spectrometry. J Agric Food Chem 2020;68(35):9329-44. https://doi.org/10.1021/acs.jafc.0c02461.

[61] Richardson CE, Hennebelle M, Otoki Y, Zamora D, Yang J, Hammock BD, et al. Lipidomic analysis of oxidized fatty acids in plant and algae oils. J Agric Food Chem 2017;65(9):1941-51. https://doi.org/10.1021/acs.jafc.6b05559.

[62] Zhou L, Zhao M, Bindler F, Marchioni E. Identification of oxidation compounds of 1-Stearoyl-2-linoleoyl-sn-glycero-3-phosphoethanolamine during thermal oxidation. J Agric Food Chem 2015;63(43):9615-20. https://doi.org/10.1021/ acs.jafc.5b03753.

[63] Le Grandois J, Marchioni E, Ennahar S, Giuffrida F, Bindler F. Identification and kinetics of oxidized compounds from phosphatidylcholine molecular species. Food Chem 2010;119(3):1233-8. https://doi.org/10.1016/j. foodchem.2009.08.042.

[64] Parchem K, Kusznierewicz B, Chmiel T, Maciołek P, Bartoszek A. Profiling and qualitative assessment of enzymatically and thermally oxidized egg yolk phospholipids using a two-step high-performance liquid chromatography protocol. J Am Oil Chem Soc 2019;96(6):693-706. https://doi.org/10.1002/ aocs. 12218.

[65] Kato S, Iseki T, Hanzawa Y, Otoki Y, Ito J, Kimura F, et al. Evaluation of the mechanisms of mayonnaise phospholipid oxidation. J Oleo Sci 2017;66(4): 369-74. https://doi.org/10.5650/jos.ess16187.

[66] Laguerre M, Tenon M, Bily A, Birtić S. Toward a spatiotemporal model of oxidation in lipid dispersions: A hypothesis-driven review. Eur J Lipid Sci Technol 2020;122(3):1900209. https://doi.org/10.1002/ejlt.201900209.

[67] Ghelichi S, Hajfathalian M, Yesiltas B, Sørensen ADM, García-Moreno PJ, Jacobsen C. Oxidation and oxidative stability in emulsions. Comprehen Rev Food Sci Food Safet 2023;22(3):1864-901. https://doi.org/10.1111/15414337.13134.

[68] Mei L, McClements DJ, Wu J, Decker EA. Iron-catalyzed lipid oxidation in emulsion as affected by surfactant, pH and NaCl . Food Chem 1998;61(3):307-12. https://doi.org/10.1016/S0308-8146(97)00058-7.

[69] Waraho T, McClements DJ, Decker EA. Mechanisms of lipid oxidation in food dispersions. Trends Food Sci Technol 2011;22(1):3-13. https://doi.org/10.1016/ j.tifs.2010.11.003.

[70] Rampon V, Lethuaut L, Mouhous-Riou N, Genot C. Interface characterization and aging of bovine serum albumin stabilized oil-in-water emulsions as revealed by front-surface fluorescence. J Agric Food Chem 2001;49(8):4046-51. https://doi. org/10.1021/jf001170y.

[71] Chen J, Li X, Cao C, Kong B, Wang H, Zhang H, et al. Effects of different pH conditions on interfacial composition and protein-lipid co-oxidation of whey protein isolate-stabilised O/W emulsions. Food Hydrocoll 2022;131:107752. https://doi.org/10.1016/j.foodhyd.2022.107752.

[72] Raudsepp P, Bruggemann DA, Andersen ML. Detection of radicals in single droplets of oil-in-water emulsions with the lipophilic fluorescent probe BODIPY (665/676) and confocal laser scanning microscopy. Free Radic Biol Med 2014;70: 233-40. https://doi.org/10.1016/j.freeradbiomed.2014.02.026.

[73] Yang S, Takeuchi M, Friedrich H, van Duynhoven JP, Hohlbein J. Unravelling mechanisms of protein and lipid oxidation in mayonnaise at multiple length scales. Food Chem 2023;402:134417. https://doi.org/10.1016/j. foodchem.2022.134417.

[74] Yang S, Verhoeff AA, Merkx DWH, van Duynhoven JPM, Hohlbein J. Quantitative spatiotemporal mapping of lipid and protein oxidation in mayonnaise. Antioxidants (Basel) 2020;9(12). https://doi.org/10.3390/antiox9121278.

[75] Berton-Carabin C, Genot C, Gaillard C, Guibert D, Ropers M. Design of interfacial films to control lipid oxidation in oil-in-water emulsions. Food Hydrocoll 2013;33 (1):99-105. https://doi.org/10.1016/j.foodhyd.2013.02.021.

[76] Berton C, Genot C, Guibert D, Ropers M-H. Effect of lateral heterogeneity in mixed surfactant-stabilized interfaces on the oxidation of unsaturated lipids in oil-in-water emulsions. J Colloid Interface Sci 2012;377(1):244-50. https://doi. org/10.1016/j.jcis.2012.03.084.

[77] Hohlbein J. Single-molecule localization microscopy as an emerging tool to probe multiscale food structures. Food Struct 2021;30:100236. https://doi.org/ 10.1016/j.foostr.2021.100236.

[78] Jabermoradi A, Yang S, Gobes MI, Van Duynhoven JPM, Hohlbein J. Enabling single-molecule localization microscopy in turbid food emulsions. Philos Trans R Soc A Math Phys Eng Sci 2022;380(2220). https://doi.org/10.1098/ rsta.2020.0164.

[79] Villeneuve P, Bourlieu-Lacanal C, Durand E, Lecomte J, McClements DJ, Decker EA. Lipid oxidation in emulsions and bulk oils: a review of the importance of micelles. Crit Rev Food Sci Nutr 2023;63(20):4687-727. https://doi.org/ 10.1080/10408398.2021.2006138.

[80] Budilarto ES, Kamal-Eldin A. The supramolecular chemistry of lipid oxidation and antioxidation in bulk oils. Eur J Lipid Sci Technol 2015;117(8):1095-137. https://doi.org/10.1002/ejlt.201400200.

[81] Chaiyasit W, Elias RJ, McClements DJ, Decker EA. Role of physical structures in bulk oils on lipid oxidation. Crit Rev Food Sci Nutr 2007;47(3):299-317. https:// doi.org/10.1080/10408390600754248.

[82] Chen B, Han A, McClements DJ, Decker EA. Physical structures in soybean oil and their impact on lipid oxidation. J Agric Food Chem 2010;58(22):11993-9. https://doi.org/10.1021/jf102763p.

[83] Cui L, McClements DJ, Decker EA. Impact of phosphatidylethanolamine on the antioxidant activity of alpha-tocopherol and trolox in bulk oil. J Agric Food Chem 2015;63(12):3288-94. https://doi.org/10.1021/acs.jafc.5b00243.

[84] Koga T, Nagao A, Terao J, Sawada K, Mukai K. Synthesis of a phosphatidyl derivative of vitamin E and its antioxidant activity in phospholipid bilayers. Lipids. 1994;29(2):83-9. https://doi.org/10.1007/BF02537147.

[85] Koga T, Terao J. Phospholipids increase radical-scavenging activity of vitamin E in a bulk oil model system. J Agric Food Chem 1995;43(6):1450-4. https://doi. org/10.1021/jf00054a007.

[86] Yoo K, Kim S, Kim M-J, Oh W, Lee J. Effects of association colloidal structures on the oxygen solubility in oil-in-water emulsion matrix. Food Sci Biotechnol 2023: 1-9. https://doi.org/10.1007/s10068-023-01338-6.

[87] Kittipongpittaya K, Panya A, McClements DJ, Decker EA. Impact of free fatty acids and phospholipids on reverse micelles formation and lipid oxidation in bulk oil. J Am Oil Chem Soc 2014;91:453-62. https://doi.org/10.1007/s11746-013-2388-8.

[88] Farhoosh R. Reliable determination of the induction period and critical reverse micelle concentration of lipid hydroperoxides exploiting a model composed of pseudo-first and -second order reaction kinetics. LWT. 2018;98:406-10. https:// doi.org/10.1016/j.lwt.2018.09.003.

[89] Merkx DW, Swager A, van Velzen EJ, van Duynhoven JP, Hennebelle M. Quantitative and predictive modelling of lipid oxidation in mayonnaise. Antioxidants. 2021;10(2):287. https://doi.org/10.3390/antiox10020287.

[90] Laguerre M, Bily A, Roller M, Birtić S. Mass transport phenomena in lipid oxidation and antioxidation. Annu Rev Food Sci Technol 2017;8:391-411. https://doi.org/10.1146/annurev-food-030216-025812.

[91] Raudsepp P, Brüggemann DA, Andersen ML. Evidence for Transfer of Radicals between Oil-in-Water Emulsion Droplets as Detected by the Probe (E,E)-3,5-Bis(4-phenyl-1,3-butadienyl)-4,4-difluoro-4-bora-3a,4a-diaza-s-indacene, BODIPY665/ 676. J Agric Food Chem 2014;62(51):12428-35. https://doi.org/10.1021/ jf504404a.

[92] Raudsepp P, Brüggemann DA, Knudsen JC, Andersen ML. Localized lipid autoxidation initiated by two-photon irradiation within single oil droplets in oil-in-water emulsions. Food Chem 2016;199:760-7. https://doi.org/10.1016/j. foodchem.2015.12.070.

[93] Banerjee C, Breitenbach T, Ogilby PR. Spatially resolved experiments to monitor the singlet oxygen initiated oxidation of lipid droplets in emulsions. ChemPhotoChem. 2018;2(7):586-95. https://doi.org/10.1002/cptc.201800005.

[94] Banerjee C, Westberg M, Breitenbach T, Bregnhøj M, Ogilby PR. Monitoring interfacial lipid oxidation in oil-in-water emulsions using spatially resolved optical techniques. Anal Chem 2017;89(11):6239-47. https://doi.org/10.1021/ acs.analchem.7b01228.

[95] Yesiltas B, García-Moreno PJ, Sørensen A-DM, Banerjee C, Anankanbil S, Guo Z, et al. The use of soy and egg phosphatidylcholines modified with Caffeic acid enhances the oxidative stability of high-fat (70%) fish oil-in-water emulsions. Coll Interf 2023;7(3):60. https://doi.org/10.3390/colloids7030060.

[96] Pryor WA. Oxy-radicals and related species: their formation, lifetimes, and reactions. Annu Rev Physiol 1986;48:657-67. https://doi.org/10.1146/annurev. ph.48.030186.003301.

[97] Termini J. Peroxyl and alkoxyl radical mediated DNA damage. In: Cutler RG, Rodriguez H, editors. Critical Reviews of Oxidative Stress and Aging. Advances in Basic Science, Diagnostics and Intervention. World Scientific Publishing Co. Pte. Ltd.; 2003. p. 39-53. https://doi.org/10.1142/9789812775733_0003.

[98] Coupland JN, Zhu Z, Wan H, McClements DJ, Nawar WW, Chinachoti P. Droplet composition affects the rate of oxidation of emulsified ethyl linoleate. J Am Oil Chem Soc 1996;73(6):795-901. https://doi.org/10.1007/BF02517957.

[99] Malassagne-Bulgarelli N, McGrath KM. Emulsion ageing: effect on the dynamics of oil exchange in oil-in-water emulsions. Soft Matter 2013;9(1):48-59. https:// doi.org/10.1039/C2SM26229K.

[100] Li P, McClements DJ, Decker EA. Application of flow cytometry as novel technology in studying lipid oxidation and mass transport phenomena in oil-inwater emulsions. Food Chem 2020;315:126225. https://doi.org/10.1016/j. foodchem.2020.126225.

[101] Nuchi CD, Hernandez P, McClements DJ, Decker EA. Ability of lipid hydroperoxides to partition into surfactant micelles and alter lipid oxidation rates in emulsions. J Agric Food Chem 2002;50(19):5445-9. https://doi.org/10.1021/ jf020095j.

[102] Verleyen T, Kamal-Eldin A, Dobarganes C, Verhé R, Dewettinck K, Huyghebaert A. Modeling of

[103] Barretto ACS, Ida EI, Silva RSF, Torres EAFS, Shimokomaki M. Empirical models for describing poultry meat lipid oxidation inhibition by natural antioxidants. J Food Compos Anal 2003;16(5):587-94. https://doi.org/10.1016/S0889-1575 (03)00023-1.

[104] Høy M, Mozuraityte R, Segtnan V, Storrø I, Bjørn Helge M, Rustad T, et al. The use of experimental design methodology for investigating a lipid oxidation rate assay. Chemom Intel Lab Syst 2008;91(2):164-72. https://doi.org/10.1016/j. chemolab.2007.11.001.

[105] Kerrihard AL, Nagy K, Craft BD, Beggio M, Pegg RB. Oxidative stability of commodity fats and oils: modeling based on fatty acid composition. J Am Oil Chem Soc 2015;92(8):1153-63. https://doi.org/10.1007/s11746-015-2686-4.

[106] Pinchuk I, Lichtenberg D. Analysis of the kinetics of lipid peroxidation in terms of characteristic time-points. Chem Phys Lipids 2014;178:63-76. https://doi.org/ 10.1016/j.chemphyslip.2013.12.001.

[107] Murado MA, Vázquez JA. Mathematical model for the characterization and objective comparison of antioxidant activities. J Agric Food Chem 2010;58(3): 1622-9. https://doi.org/10.1021/jf903709z.

[108] Farhoosh R. A reconsidered approach providing kinetic parameters and rate constants to analyze the oxidative stability of bulk lipid systems. Food Chem 2020;327:127088. https://doi.org/10.1016/j.foodchem.2020.127088.

[109] Farhoosh R. New insights into the kinetic and thermodynamic evaluations of lipid peroxidation. Food Chem 2022;375:131659. https://doi.org/10.1016/j. foodchem.2021.131659.

[110] Li X, Wu G, Huang J, Zhang H, Jin Q, Wang X. Kinetic models to understand the coexistence of formation and decomposition of hydroperoxide during lipid oxidation. Food Res Int 2020;136:109314. https://doi.org/10.1016/j. foodres.2020.109314.

[111] Aragao GMF, Corradini MG, Peleg M. A phenomenological model of the peroxide Value’s rise and fall during lipid oxidation. J Am Oil Chem Soc 2008;85(12):1143. https://doi.org/10.1007/s11746-008-1305-z.

[112] Ozilgen S, Ozilgen M. Kinetic model of lipid oxidation in foods. J Food Sci 1990; 55(2):498-501. https://doi.org/10.1111/j.1365-2621.1990.tb06795.x.

[113] McPherson PAC, Bole A, Cruz KA, Young IS, McEneny J. A curvilinear approach to the kinetic analysis of linoleate peroxidation in aqueous liposomes by 2,2’azobis (2-amidoinopropane) dihydrochloride. Chem Phys Lipids 2012;165(6):682-8. https://doi.org/10.1016/j.chemphyslip.2012.07.004.

[114] Merkx DW, Hong GS, Ermacora A, Van Duynhoven JP. Rapid quantitative profiling of lipid oxidation products in a food emulsion by 1H NMR. Anal Chem 2018;90(7):4863-70. https://doi.org/10.1021/acs.analchem.8b00380.

[115] Nguyen KA, Hennebelle M, van Duynhoven JPM, Dubbelboer A, Boerkamp VJP, Wierenga PA. Mechanistic kinetic modelling of lipid oxidation in vegetable oils to estimate shelf-life. Food Chem 2024;433:137266. https://doi.org/10.1016/j. foodchem.2023.137266.

[116] Schroën K, Berton-Carabin CC. A unifying approach to lipid oxidation in emulsions: modelling and experimental validation. Food Res Int 2022;160: 111621. https://doi.org/10.1016/j.foodres.2022.111621.

[117] Tan CP, Che Man YB, Selamat J, Yusoff MSA. Application of arrhenius kinetics to evaluate oxidative stability in vegetable oils by isothermal differential scanning calorimetry. J Am Oil Chem Soc 2001;78(11):1133-8. https://doi.org/10.1007/ s11746-001-0401-1.

[118] Farhoosh R. Critical kinetic parameters and rate constants representing lipid peroxidation as affected by temperature. Food Chem 2021;340:128137. https:// doi.org/10.1016/j.foodchem.2020.128137.

[119] Sullivan JC, Budge SM, St-Onge M. Modeling the primary oxidation in commercial fish oil preparations. Lipids. 2011;46(1):87-93. https://doi.org/

[120] Shim SD, Lee SJ. Shelf-life prediction of perilla oil by considering the induction period of lipid oxidation. Eur J Lipid Sci Technol 2011;113(7):904-9. https://doi. org/10.1002/ejlt.201000325.

[121] Bravo-Diaz C. Advances in the control of lipid peroxidation in oil-in-water emulsions: kinetic approaches(dagger). Crit Rev Food Sci Nutr 2022:1-33. https://doi.org/10.1080/10408398.2022.2029827.

[122] Romsted LS, Bravo-Díaz C. Modeling chemical reactivity in emulsions. Curr Opin Colloid Interface Sci 2013;18(1):3-14. https://doi.org/10.1016/j. cocis.2012.11.001.

[123] Genot C. Distributions of phenolic acid antioxidants between the interfacial and aqueous regions of corn oil emulsions-a commentary. Eur J Lipid Sci Technol 2015;117(11):1684-6. https://doi.org/10.1002/ejlt.201500210.

[124] Nazir A, Schroën K, Boom R. Premix emulsification: A review. J Membr Sci 2010; 362(1):1-11. https://doi.org/10.1016/j.memsci.2010.06.044.

[125] Costa ALR, Gomes A, Andrade CCPD, Cunha RL. Emulsifier functionality and process engineering: Progress and challenges. Food Hydrocoll 2017;68:69-80. https://doi.org/10.1016/j.foodhyd.2016.10.012.

[126] Neves MA, Wang Z, Kobayashi I, Nakajima M. Assessment of oxidative stability in fish oil-in-water emulsions: effect of emulsification process, droplet size and storage temperature. J Food Process Eng 2017;40(1):e12316. https://doi.org/ 10.1111/jfpe.12316.

[127] Walker R, Decker EA, McClements DJ. Development of food-grade nanoemulsions and emulsions for delivery of omega-3 fatty acids: opportunities and obstacles in the food industry. Food Funct 2015;6(1):42-55. https://doi.org/10.1039/ c4fo00723a.

[128] Horn AF, Barouh N, Nielsen NS, Baron CP, Jacobsen C. Homogenization pressure and temperature affect protein partitioning and oxidative stability of emulsions. J Am Oil Chem Soc 2013;90(10):1541-50. https://doi.org/10.1007/s11746-013-2292-2.

[129] Let MB, Jacobsen C, Sorensen AD, Meyer AS. Homogenization conditions affect the oxidative stability of fish oil enriched milk emulsions: lipid oxidation. J Agric Food Chem 2007;55(5):1773-80. https://doi.org/10.1021/jf062391s.

[130] Sorensen AD, Baron CP, Let MB, Bruggemann DA, Pedersen LR, Jacobsen C. Homogenization conditions affect the oxidative stability of fish oil enriched milk emulsions: oxidation linked to changes in protein composition at the oil-water interface. J Agric Food Chem 2007;55(5):1781-9. https://doi.org/10.1021/ jf0623900.

[131] Hu M, McClements DJ, Decker EA. Lipid oxidation in corn oil-in-water emulsions stabilized by casein, whey protein isolate, and soy protein isolate. J Agric Food Chem 2003;51(6):1696-700. https://doi.org/10.1021/jf020952j.

[132] Shao Y, Tang C-H. Characteristics and oxidative stability of soy protein-stabilized oil-in-water emulsions: influence of ionic strength and heat pretreatment. Food Hydrocoll 2014;37:149-58. https://doi.org/10.1016/j.foodhyd.2013.10.030.

[133] Kellerby SS, Gu YS, McClements DJ, Decker EA. Lipid oxidation in a menhaden oil-in-water emulsion stabilized by sodium Caseinate cross-linked with transglutaminase. J Agric Food Chem 2006;54(26):10222-7. https://doi.org/ 10.1021/jf062143w.

[134] Lesmes U, Sandra S, Decker EA, McClements DJ. Impact of surface deposition of lactoferrin on physical and chemical stability of omega-3 rich lipid droplets stabilised by caseinate. Food Chem 2010;123(1):99-106. https://doi.org/ 10.1016/j.foodchem.2010.04.007.

[135] Chen B, Li H, Ding Y, Rao J. Improvement of physicochemical stabilities of emulsions containing oil droplets coated by non-globular protein-beet pectin complex membranes. Food Res Int 2011;44(5):1468-75. https://doi.org/ 10.1016/j.foodres.2011.03.024.

[136] Gudipati V, Sandra S, McClements DJ, Decker EA. Oxidative stability and in vitro digestibility of fish oil-in-water emulsions containing multilayered membranes. J Agric Food Chem 2010;58(13):8093-9. https://doi.org/10.1021/jf101348c.

[137] McClements DJ, Decker E. Interfacial antioxidants: A review of natural and synthetic emulsifiers and Coemulsifiers that can inhibit lipid oxidation. J Agric Food Chem 2018;66(1):20-35. https://doi.org/10.1021/acs.jafc.7b05066.

[138] Dickinson E. Mixed biopolymers at interfaces: competitive adsorption and multilayer structures. Food Hydrocoll 2011;25(8):1966-83. https://doi.org/ 10.1016/j.foodhyd.2010.12.001.

[139] García-Moreno PJ, Horn AF, Jacobsen C. Influence of casein-phospholipid combinations as emulsifier on the physical and oxidative stability of fish oil-inwater emulsions. J Agric Food Chem 2014;62(5):1142-52. https://doi.org/ 10.1021/jf405073x.

[140] Yesiltas B, Soria Caindec AM, García-Moreno PJ, Echers SG, Olsen TH, Jones NC, et al. Physical and oxidative stability of fish oil-in-water emulsions stabilized with emulsifier peptides derived from seaweed, methanotrophic bacteria and potato proteins. Colloids Surf A Physicochem Eng Asp 2023;663:131069. https://doi. org/10.1016/j.colsurfa.2023.131069.

[141] Yesiltas B, Torkkeli M, Almásy L, Dudás Z, García-Moreno PJ, Sørensen A-DM, et al. Small-angle neutron scattering study of high fat fish oil-in-water emulsion stabilized with sodium Caseinate and phosphatidylcholine. Langmuir. 2020;36 (9):2300-6. https://doi.org/10.1021/acs.langmuir.9b03269.

[142] Ozturk B, McClements DJ. Progress in natural emulsifiers for utilization in food emulsions. Curr Opin Food Sci 2016;7:1-6. https://doi.org/10.1016/j. cofs.2015.07.008.

[143] Sharif HR, Williams PA, Sharif MK, Abbas S, Majeed H, Masamba KG, et al. Current progress in the utilization of native and modified legume proteins as emulsifiers and encapsulants-A review. Food Hydrocoll 2018;76:2-16. https:// doi.org/10.1016/j.foodhyd.2017.01.002.

[144] Burger TG, Zhang Y. Recent progress in the utilization of pea protein as an emulsifier for food applications. Trends Food Sci Technol 2019;86:25-33. https:// doi.org/10.1016/j.tifs.2019.02.007.

[145] Lam RSH, Nickerson MT. Food proteins: A review on their emulsifying properties using a structure-function approach. Food Chem 2013;141(2):975-84. https:// doi.org/10.1016/j.foodchem.2013.04.038.

[146] Schutyser M, Van der Goot A. The potential of dry fractionation processes for sustainable plant protein production. Trends Food Sci Technol 2011;22(4): 154-64. https://doi.org/10.1016/j.tifs.2010.11.006.

[147] Faraji H, McClements DJ, Decker EA. Role of continuous phase protein on the oxidative stability of fish oil-in-water emulsions. J Agric Food Chem 2004;52(14): 4558-64. https://doi.org/10.1021/jf035346i.

[148] Feng J, Schroën K, Fogliano V, Berton-Carabin C. Antioxidant potential of nonmodified and glycated soy proteins in the continuous phase of oil-in-water emulsions. Food Hydrocoll 2021;114:106564. https://doi.org/10.1016/j. foodhyd.2020.106564.

[149] Hinderink EBA, Schröder A, Sagis L, Schroën K, Berton-Carabin CC. Physical and oxidative stability of food emulsions prepared with pea protein fractions. LWT. 2021;146:111424. https://doi.org/10.1016/j.lwt.2021.111424.

[150] Liu C, Bhattarai M, Mikkonen KS, Heinonen M. Effects of enzymatic hydrolysis of fava bean protein isolate by Alcalase on the physical and oxidative stability of oil-in-water emulsions. J Agric Food Chem 2019;67(23):6625-32. https://doi.org/ 10.1021/acs.jafc.9b00914.

[151] Keuleyan E, Gélébart P, Beaumal V, Kermarrec A, Ribourg-Birault L, Le Gall S, et al. Pea and lupin protein ingredients: new insights into endogenous lipids and the key effect of high-pressure homogenization on their aqueous suspensions. Food Hydrocoll 2023;141:108671. https://doi.org/10.1016/j. foodhyd.2023.108671.

[152] Pei Y, Deng Q, McClements DJ, Li J, Li B. Impact of Phytic acid on the physical and oxidative stability of protein-stabilized oil-in-water emulsions. Food Biophys 2020;15(4):433-41. https://doi.org/10.1007/s11483-020-09641-z.

[153] Dickinson E. Advances in food emulsions and foams: reflections on research in the neo-Pickering era. Curr Opin Food Sci 2020;33:52-60. https://doi.org/10.1016/j. cofs.2019.12.009.

[154] Calabrese V, Courtenay JC, Edler KJ, Scott JL. Pickering emulsions stabilized by naturally derived or biodegradable particles. Curr Opin Green Sustain Chem 2018;12:83-90. https://doi.org/10.1016/j.cogsc.2018.07.002.

[155] Dickinson E. Biopolymer-based particles as stabilizing agents for emulsions and foams. Food Hydrocoll 2017;68:219-31. https://doi.org/10.1016/j. foodhyd.2016.06.024.

[156] Linke C, Drusch S. Pickering emulsions in foods – opportunities and limitations. Crit Rev Food Sci Nutr 2018;58(12):1971-85. https://doi.org/10.1080/ 10408398.2017 .1290578.

[157] Rayner M. Current status on novel ways for stabilizing food dispersions by oleosins, particles and microgels. Curr Opin Food Sci 2015;3:94-109. https://doi. org/10.1016/j.cofs.2015.05.006.

[158] Tavernier I, Wijaya W, Van der Meeren P, Dewettinck K, Patel AR. Food-grade particles for emulsion stabilization. Trends Food Sci Technol 2016;50:159-74. https://doi.org/10.1016/j.tifs.2016.01.023.

[159] Berton-Carabin C, Schröder A, Schroën K, Laguerre M. Chapter 14 – Lipid oxidation in Pickering emulsions. In: García-Moreno PJ, editor. Omega-3 Delivery Systems. Academic Press; 2021. p. 275-93. https://doi.org/10.1016/B978-0-12-821391-9.00011-9.

[160] Kargar M, Fayazmanesh K, Alavi M, Spyropoulos F, Norton IT. Investigation into the potential ability of Pickering emulsions (food-grade particles) to enhance the oxidative stability of oil-in-water emulsions. J Colloid Interface Sci 2012;366(1): 209-15. https://doi.org/10.1016/j.jcis.2011.09.073.

[161] Kargar M, Spyropoulos F, Norton IT. The effect of interfacial microstructure on the lipid oxidation stability of oil-in-water emulsions. J Colloid Interface Sci 2011; 357(2):527-33. https://doi.org/10.1016/j.jcis.2011.02.019.

[162] Xiao J, Li C, Huang Q. Kafirin nanoparticle-stabilized Pickering emulsions as Oral delivery vehicles: physicochemical stability and in vitro digestion profile. J Agric Food Chem 2015;63(47):10263-70. https://doi.org/10.1021/acs.jafc.5b04385.

[163] Huang X-N, Zhou F-Z, Yang T, Yin S-W, Tang C-H, Yang X-Q. Fabrication and characterization of Pickering high internal phase emulsions (HIPEs) stabilized by chitosan-caseinophosphopeptides nanocomplexes as oral delivery vehicles. Food Hydrocoll 2019;93:34-45. https://doi.org/10.1016/j.foodhyd.2019.02.005.

[164] Schröder A, Sprakel J, Boerkamp W, Schroën K, Berton-Carabin CC. Can we prevent lipid oxidation in emulsions by using fat-based Pickering particles? Food Res Int 2019;120:352-63. https://doi.org/10.1016/j.foodres.2019.03.004.

[165] Okubanjo SS, Loveday SM, Ye A, Wilde PJ, Singh H. Droplet-stabilized oil-inwater emulsions protect unsaturated lipids from oxidation. J Agric Food Chem 2019;67(9):2626-36. https://doi.org/10.1021/acs.jafc.8b02871.

[166] Timgren A, Rayner M, Dejmek P, Marku D, Sjoo M. Emulsion stabilizing capacity of intact starch granules modified by heat treatment or octenyl succinic anhydride. Food Sci Nutr 2013;1(2):157-71. https://doi.org/10.1002/fsn3.17.

[167] Barden L, Barouh N, Villeneuve P, Decker E. Impact of hydrophobicity on antioxidant efficacy in low-moisture food. J Agric Food Chem 2015;63(24): 5821-7. https://doi.org/10.1021/acs.jafc.5b01085.

[168] Barden L, Decker EA. Lipid oxidation in low-moisture food: A review. Crit Rev Food Sci Nutr 2016;56(15):2467-82. https://doi.org/10.1080/ 10408398.2013.848833.

[169] Ferreira da Silveira TF, Laguerre M, Bourlieu-Lacanal C, Lecomte J, Durand E, Figueroa-Espinoza MC, et al. Impact of surfactant concentration and antioxidant mode of incorporation on the oxidative stability of oil-in-water nanoemulsions. LWT. 2021;141:110892. https://doi.org/10.1016/j.lwt.2021.110892.

[170] Inchingolo R, Bayram I, Uluata S, Kiralan SS, Rodriguez-Estrada MT, McClements DJ, et al. Ability of sodium dodecyl sulfate (SDS) micelles to increase the antioxidant activity of alpha-tocopherol. J Agric Food Chem 2021;69(20): 5702-8. https://doi.org/10.1021/acs.jafc.1c01199.

[171] McClements DJ, Dungan SR. Factors that affect the rate of oil exchange between oil-in-water emulsion droplets stabilized by a nonionic surfactant: droplet size, surfactant concentration, and ionic strength. J Phys Chem 1993;97(28):7304-8. https://doi.org/10.1021/j100130a030.

[172] Raudsepp P, Brüggemann DA, Lenferink A, Otto C, Andersen ML. Oxidative stabilization of mixed mayonnaises made with linseed oil and saturated mediumchain triglyceride oil. Food Chem 2014;152:378-85. https://doi.org/10.1016/j. foodchem.2013.11.141.

[173] Cho YJ, McClements DJ, Decker EA. Ability of surfactant micelles to alter the physical location and reactivity of iron in oil-in-water emulsion. J Agric Food Chem 2002;50(20):5704-10. https://doi.org/10.1021/jf020433g.

[174] Anton M. Egg yolk: structures, functionalities and processes. J Sci Food Agric 2013;93(12):2871-80. https://doi.org/10.1002/jsfa.6247.

[175] Samaraweera H, Zhang WG, Lee EJ, Ahn DU. Egg yolk phosvitin and functional phosphopeptides. J Food Sci 2011;76(7):R143-50. https://doi.org/10.1111/ j.1750-3841.2011.02291.x.

[176] Hu M, McClements DJ, Decker EA. Impact of whey protein emulsifiers on the oxidative stability of Salmon oil-in-water emulsions. J Agric Food Chem 2003;51 (5):1435-9. https://doi.org/10.1021/jf0203794.

[177] Sugiarto M, Ye A, Taylor MW, Singh H. Milk protein-iron complexes: inhibition of lipid oxidation in an emulsion. Dairy Sci Technol 2010;90(1):87-98. https://doi. org/10.1051/dst/2009053.

[178] Villiere A, Viau M, Bronnec I, Moreau N, Genot C. Oxidative stability of bovine serum albumin- and sodium Caseinate-stabilized emulsions depends on metal availability. J Agric Food Chem 2005;53(5):1514-20. https://doi.org/10.1021/ jf0486951.

[179] Elias RJ, Kellerby SS, Decker EA. Antioxidant activity of proteins and peptides. Crit Rev Food Sci Nutr 2008;48(5):430-41. https://doi.org/10.1080/ 10408390701425615.

[180] Panya A, Laguerre M, Bayrasy C, Lecomte J, Villeneuve P, McClements DJ, et al. An investigation of the versatile antioxidant mechanisms of action of rosmarinate alkyl esters in oil-in-water emulsions. J Agric Food Chem 2012;60(10):2692-700. https://doi.org/10.1021/jf204848b.

[181] Martinez-Senra T, Losada-Barreiro S, Bravo-Diaz C. Efficiency of delta-tocopherol in inhibiting lipid oxidation in emulsions: effects of surfactant charge and of surfactant concentration. Antioxidants (Basel) 2023;12(6). https://doi.org/ 10.3390/antiox12061158.

[182] Losada-Barreiro S, Paiva-Martins F, Bravo-Diaz C. Partitioning of antioxidants in edible oil-water binary systems and in oil-in-water emulsions. Antioxidants (Basel) 2023;12(4). https://doi.org/10.3390/antiox12040828.

[183] Kiralan SS, Doğu-Baykut E, Kittipongpittaya K, McClements DJ, Decker EA. Increased antioxidant efficacy of tocopherols by surfactant Solubilization in oil-in-water emulsions. J Agric Food Chem 2014;62(43):10561-6. https://doi.org/ 10.1021/jf503115j.

[184] Richards MP, Chaiyasit W, McClements DJ, Decker EA. Ability of surfactant micelles to alter the partitioning of phenolic antioxidants in oil-in-water emulsions. J Agric Food Chem 2002;50(5):1254-9. https://doi.org/10.1021/ jf011324p.

[185] Dai T, Chen J, McClements DJ, Hu P, Ye X, Liu C, et al. Protein-polyphenol interactions enhance the antioxidant capacity of phenolics: analysis of rice glutelin-procyanidin dimer interactions. Food Funct 2019;10(2):765-74. https:// doi.org/10.1039/c8fo02246a.

[186] Schild K, Sonnichsen FD, Martin D, Garamus VM, Van der Goot AJ, Schwarz K, et al. Unraveling the effects of low protein-phenol binding affinity on the structural properties of beta-lactoglobulin. Food Chem 2023;426:136496. https://doi.org/10.1016/j.foodchem.2023.136496.

[187] Tang L, Cao M, Liao C, Liu R, Chang M, Wang X. Migration of tocopherols from the oil phase to the oil-water interface using phospholipids improved the oxidative stability of O/W emulsions. Food Chem 2023;414:135719. https://doi. org/10.1016/j.foodchem.2023.135719.

[188] Chen J, Li X, Kong B, Chen Q, Liu Q. Comparative study of protein-lipid cooxidation in whey protein isolate-stabilised oil-in-water emulsions prepared by different homogenisation methods. Colloids Surf A Physicochem Eng Asp 2022; 633:127916. https://doi.org/10.1016/j.colsurfa.2021.127916.

[189] Chen J, Zhao J, Kong B, Chen Q, Liu Q, Liu C. Comparative study of oxidative structural modifications of Unadsorbed and adsorbed proteins in whey protein isolate-stabilized oil-in-water emulsions under the stress of primary and secondary lipid oxidation products. Foods. 2021;10(3). https://doi.org/10.3390/ foods10030593.

[190] Donnelly JL, Decker EA, McClements DJ. Iron-catalyzed oxidation of menhaden oil as affected by emulsifiers. J Food Sci 1998;63(6):997-1000. https://doi.org/ 10.1111/j.1365-2621.1998.tb15841.x.

[191] Ma KK, Greis M, Lu J, Nolden AA, McClements DJ, Kinchla AJ. Functional performance of plant proteins. Foods 2022;11:4. https://doi.org/10.3390/ foods11040594.

[192] Donbrow M, Azaz E, Pillersdorf A. Autoxidation of polysorbates. J Pharm Sci 1978;67(12):1676-81. https://doi.org/10.1002/jps.2600671211.

[193] Hamburger R, Azaz E, Donbrow M. Autoxidation of polyoxyethylenic non-ionic surfactants and of polyethylene glycols. Pharm Acta Helv 1975;50(1-2):10-7.

[194] Lever M. Peroxides in detergents as interfering factors in biochemical analysis. Anal Biochem 1977;83(1):274-84. https://doi.org/10.1016/0003-2697(77) 90536-X.

[195] Jaeger J, Sorensen K, Wolff SP. Peroxide accumulation in detergents. J Biochem Biophys Methods 1994;29(1):77-81. https://doi.org/10.1016/0165-022x(94) 90058-2.

[196] Mancuso JR, McClements DJ, Decker EA. The effects of surfactant type, pH , and chelators on the oxidation of salmon oil-in-water emulsions. J Agric Food Chem 1999;47(10):4112-6. https://doi.org/10.1021/jf990203a.

[197] Ha E, Wang W, Wang YJ. Peroxide formation in polysorbate 80 and protein stability. J Pharm Sci 2002;91(10):2252-64. https://doi.org/10.1002/jps.10216.

[198] Segal R, Azaz E, Donbrow M. Peroxide removal from non-ionic surfactants. J Pharm Pharmacol 1979;31(1):39-40. https://doi.org/10.1111/j.20427158.1979.tb13418.x.

[199] Donbrow M, Hamburger R, Azaz E, Pillersdorf A. Development of acidity in nonionic surfactants: formic and acetic acid. Analyst. 1978;103(1225):400-2. https://doi.org/10.1039/AN9780300400.

[200] Kerwin BA. Polysorbates 20 and 80 used in the formulation of protein biotherapeutics: structure and degradation pathways. J Pharm Sci 2008;97(8): 2924-35. https://doi.org/10.1002/jps. 21190.

[201] Yao J, Dokuru DK, Noestheden M, Park SS, Kerwin BA, Jona J, et al. A quantitative kinetic study of polysorbate autoxidation: the role of unsaturated fatty acid ester substituents. Pharm Res 2009;26(10):2303-13. https://doi.org/ 10.1007/s11095-009-9946-7.

[202] Kishore RS, Pappenberger A, Dauphin IB, Ross A, Buergi B, Staempfli A, et al. Degradation of polysorbates 20 and 80: studies on thermal autoxidation and hydrolysis. J Pharm Sci 2011;100(2):721-31. https://doi.org/10.1002/ jps. 22290.

[203] Hvattum E, Yip WL, Grace D, Dyrstad K. Characterization of polysorbate 80 with liquid chromatography mass spectrometry and nuclear magnetic resonance spectroscopy: specific determination of oxidation products of thermally oxidized polysorbate 80. J Pharm Biomed Anal 2012;62:7-16. https://doi.org/10.1016/j. jpba.2011.12.009.

[204] Li X, Wang Z, Zheng B, Wang Y, Zhang J. Novel strategy to rapidly profile and identify oxidized species of Polysorbate 80 using ultra-high-performance liquid chromatography coupled with high-resolution mass spectrometry. Anal Chem 2023;95(24):9156-63. https://doi.org/10.1021/acs.analchem.2c04956.

[205] Bai L, Zhang Y, Zhang C, Lu Y, Li Z, Huang G, et al. Investigation of excipients impact on polysorbate 80 degradation in biopharmaceutical formulation buffers.

[206] Mittag JJ, Trutschel ML, Kruschwitz H, Mader K, Buske J, Garidel P. Characterization of radicals in polysorbate 80 using electron paramagnetic resonance (EPR) spectroscopy and spin trapping. Int J Pharm X 2022;4:100123. https://doi.org/10.1016/j.ijpx.2022.100123.

[207] Larson NR, Wei Y, Prajapati I, Chakraborty A, Peters B, Kalonia C, et al. Comparison of Polysorbate 80 hydrolysis and oxidation on the aggregation of a monoclonal antibody. J Pharm Sci 2020;109(1):633-9. https://doi.org/10.1016/ j.xphs.2019.10.069.

[208] Peters BH, Wei Y, Middaugh CR, Schoneich C. Intra-micellar and extra-micellar oxidation in phosphate and histidine buffers containing Polysorbate 80. J Pharm Sci 2022;111(9):2435-44. https://doi.org/10.1016/j.xphs.2022.06.011.

[209] Nuchi CD, McClements DJ, Decker EA. Impact of tween 20 hydroperoxides and iron on the oxidation of methyl linoleate and salmon oil dispersions. J Agric Food Chem 2001;49(10):4912-6. https://doi.org/10.1021/jf010370m.

[210] Schwarz K, Huang SW, German JB, Tiersch B, Hartmann J, Frankel EN. Activities of antioxidants are affected by colloidal properties of oil-in-water and water-in-oil emulsions and bulk oils. J Agric Food Chem 2000;48(10):4874-82. https://doi. org/10.1021/jf991289a.

[211] Mabrouk AF, Dugan Jr L. Kinetic investigation into glucose-, fructose-, and sucrose-activated autoxidation of methyl linoleate emulsion. J Am Oil Chem Soc 1961;38(12):692-5. https://doi.org/10.1007/BF02633057.

[212] Haahr AM, Jacobsen C. Emulsifier type, metal chelation and pH affect oxidative stability of n-3-enriched emulsions. Eur J Lipid Sci Technol 2008;110(10): 949-61. https://doi.org/10.1002/ejlt.200800035.

[213] Kasaikina O, Golyavin A, Krugovov D, Kartasheva Z, Pisarenko L. Micellar catalysis in the oxidation of lipids. Mosc Univ Chem Bull 2010;65:206-9. https:// doi.org/10.3103/S0027131410030193.

[214] Uluata S, McClements DJ, Decker EA. Physical stability, autoxidation, and photosensitized oxidation of omega-3 oils in Nanoemulsions prepared with natural and synthetic surfactants. J Agric Food Chem 2015;63(42):9333-40. https://doi.org/10.1021/acs.jafc.5b03572.

[215] Gutiérrez-Méndez N, Chavez-Garay DR, Leal-Ramos MY. Lecithins: A comprehensive review of their properties and their use in formulating microemulsions. J Food Biochem 2022;46(7):e14157. https://doi.org/10.1111/ jfbc. 14157.

[216] Caparosa MH, Hartel RW. Characterizing lecithin interactions in chocolate using interfacial properties and rheology. J Am Oil Chem Soc 2020;97(12):1309-17. https://doi.org/10.1002/aocs.12419.

[217] Alhajj MJ, Montero N, Yarce CJ, Salamanca CH. Lecithins from vegetable, land, and marine animal sources and their potential applications for cosmetic, food, and pharmaceutical sectors. Cosmetics. 2020;7(4):87. https://doi.org/10.3390/ cosmetics7040087.

[218] Robert C, Couëdelo L, Vaysse C, Michalski M-C. Vegetable lecithins: A review of their compositional diversity, impact on lipid metabolism and potential in cardiometabolic disease prevention. Biochimie. 2020;169:121-32. https://doi. org/10.1016/j.biochi.2019.11.017.

[219] Dacaranhe CD, Terao J. A unique antioxidant activity of phosphatidylserine on iron-induced lipid peroxidation of phospholipid bilayers. Lipids. 2001;36(10): 1105-10. https://doi.org/10.1007/s11745-001-0820-7.

[220] Cardenia V, Waraho T, Rodriguez-Estrada MT, Julian McClements D, Decker EA. Antioxidant and Prooxidant activity behavior of phospholipids in stripped soybean oil-in-water emulsions. J Am Oil Chem Soc 2011;88(9):1409-16. https:// doi.org/10.1007/s11746-011-1807-y.

[221] Judde A, Villeneuve P, Rossignol-Castera A, Le Guillou A. Antioxidant effect of soy lecithins on vegetable oil stability and their synergism with tocopherols. J Am Oil Chem Soc 2003;80(12):1209-15. https://doi.org/10.1007/s11746-003-08444.

[222] Hildebrand D, Terao J, Kito M. Phospholipids plus tocopherols increase soybean oil stability. J Am Oil Chem Soc 1984;61(3):552-5. https://doi.org/10.1007/ BF02677029.

[223] Khan MA, Shahidi F. Tocopherols and phospholipids enhance the oxidative stability of borage and evening primrose triacylglycerols. J Food Lipids 2000;7 (3):143-50. https://doi.org/10.1111/j.1745-4522.2000.tb00167.x.

[224] Kashima M, Cha G-S, Isoda Y, Hirano J, Miyazawa T. The antioxidant effects of phospholipids on perilla oil. J Am Oil Chem Soc 1991;68:119-22. https://doi. org/10.1007/BF02662331.

[225] Lee J, Choe E. Effects of phospholipids on the antioxidant activity of alphatocopherol in the singlet oxygen oxidation of canola oil. N Biotechnol 2011;28(6): 691-7. https://doi.org/10.1016/j.nbt.2011.04.013.

[226] Weng X, Gordon MH. Antioxidant synergy between phosphatidyl ethanolamine and

[227] Doert M, Jaworska K, Moersel J-T, Kroh LW. Synergistic effect of lecithins for tocopherols: lecithin-based regeneration of

[228] Takenaka A, Hosokawa M, Miyashita K. Unsaturated phosphatidylethanolamine as effective synergist in combination with

[229] Shimajiri J, Shiota M, Hosokawa M, Miyashita K. Synergistic antioxidant activity of milk sphingomyeline and its sphingoid base with

[230] Hidalgo FJ, Nogales F, Zamora R. Changes produced in the antioxidative activity of phospholipids as a consequence of their oxidation. J Agric Food Chem 2005;53 (3):659-62. https://doi.org/10.1021/jf0483220.

[231] Bandarra NM, Campos RM, Batista I, Nunes ML, Empis JM. Antioxidant synergy of

[232] Lu FS, Nielsen NS, Baron CP, Diehl BW, Jacobsen C. Oxidative stability of dispersions prepared from purified marine phospholipid and the role of alphatocopherol. J Agric Food Chem 2012;60(50):12388-96. https://doi.org/10.1021/ jf303560f.

[233] Bacot S, Bernoud-Hubac N, Chantegrel B, Deshayes C, Doutheau A, Ponsin G, et al. Evidence for in situ ethanolamine phospholipid adducts with hydroxyalkenals. J Lipid Res 2007;48(4):816-25. https://doi.org/10.1194/jlr.M600340JLR200.

[234] van Nieuwenhuyzen W, Tomás MC. Update on vegetable lecithin and phospholipid technologies. Eur J Lipid Sci Technol 2008;110(5):472-86. https:// doi.org/10.1002/ejlt.200800041.

[235] Lu F, Nielsen NS, Baron CP, Jacobsen C. Marine phospholipids: the current understanding of their oxidation mechanisms and potential uses for food fortification. Crit Rev Food Sci Nutr 2017;57(10):2057-70. https://doi.org/ 10.1080/10408398.2014.925422.

[236] Dong Y, Yong VW. Oxidized phospholipids as novel mediators of neurodegeneration. Trends Neurosci 2022. https://doi.org/10.1016/j. tins.2022.03.002.

[237] Dushianthan A, Postle A. Methodology to detect oxidised phospholipids and their relevance in disease. Biochem Soc Trans 2021;49(3):1241-50. https://doi.org/ 10.1042/BST20200852.

[238] Nie J, Yang J, Wei Y, Wei X. The role of oxidized phospholipids in the development of disease. Mol Aspects Med 2020;76:100909. https://doi.org/ 10.1016/j.mam.2020.100909.

[239] Reis A, Spickett CM. Chemistry of phospholipid oxidation. Biochim Biophys Acta 2012;1818(10):2374-87. https://doi.org/10.1016/j.bbamem.2012.02.002.

[240] Henna Lu FS, Nielsen NS, Timm-Heinrich M, Jacobsen C. Oxidative stability of marine phospholipids in the liposomal form and their applications. Lipids. 2011; 46(1):3-23. https://doi.org/10.1007/s11745-010-3496-y.

[241] Thomsen BR, Haugsgjerd BO, Griinari M, Lu HFS, Bruheim I, Vogt G, et al. Investigation of oxidative degradation and non-enzymatic browning reactions in krill and fish oils. Eur J Lipid Sci Technol 2013;115(12):1357-66. https://doi. org/10.1002/ejlt.201300141.

[242] Igene J, Pearson A, Dugan Jr L, Price J. Role of triglycerides and phospholipids on development of rancidity in model meat systems during frozen storage. Food Chem 1980;5(4):263-76. https://doi.org/10.1016/0308-8146(80)90048-5.

[243] Igene J, Pearson A, Gray J. Effects of length of frozen storage, cooking and holding temperatures upon component phospholipids and the fatty acid composition of meat triglycerides and phospholipids. Food Chem 1981;7(4): 289-303. https://doi.org/10.1016/0308-8146(81)90034-0.

[244] Pikul J, Kummerow FA. Relative role of individual phospholipids on thiobarbituric acid reactive substances formation in chicken meat, skin and swine aorta. J Food Sci 1990;55(5):1243-8. https://doi.org/10.1111/j.13652621.1990.tb03907.x.