DOI: https://doi.org/10.1016/j.buildenv.2024.111250

تاريخ النشر: 2024-01-29

المواد الميتامادية الصوتية لامتصاص الصوت والعزل في المباني

معلومات المقال

الكلمات المفتاحية:

عزل الصوت

تقليل الصوت

التهوية

تصميم المباني

الملخص

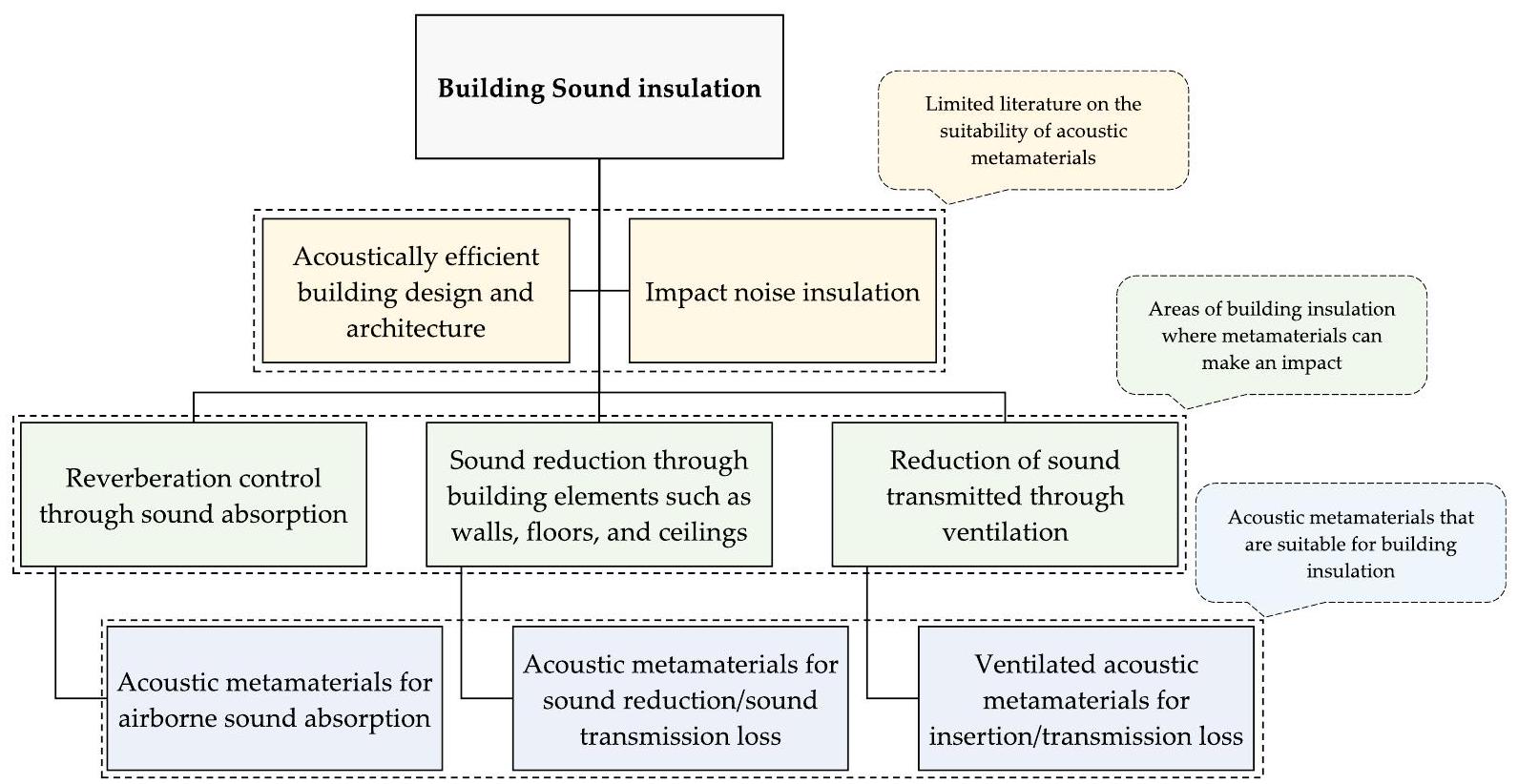

على الرغم من ظهور المواد الميتامادية الصوتية التي تتمتع بامتصاص صوتي ممتاز وفقدان نقل، إلا أن اعتمادها في عزل الصوت في المباني كان محدودًا. لا يزال تصميم عزل الصوت في المباني مستندًا إلى الأداء الصوتي للمواد التقليدية، حيث يتعارض قانون الكتلة مع خفة الوزن عندما يتعلق الأمر بالتصميم الصوتي. في أي حال، تعاني المباني القريبة من البيئات المزعجة مثل الطرق السريعة، وخطوط السكك الحديدية، والمطارات من تلوث ضوضائي منخفض التردد بشكل كبير. على الرغم من أن النطاق الترددي المحدود للمواد الميتامادية الصوتية يمثل مشكلة رئيسية تحد من تطبيقها، فإن دمج وحدات ميتامادية تتفاعل عند ترددات مختلفة جنبًا إلى جنب مع حلول تقليدية متعددة الطبقات يمكن أن يوفر عزل صوتي ممتاز في المباني. تقدم المراجعة المواد الميتامادية الصوتية، مع التركيز بشكل خاص على امتصاص الصوت الممتاز وفقدان النقل/الإدخال كخصائص حاسمة لعزل الصوت الفعال في المباني. تكشف الورقة عن مجموعة متنوعة من المواد الميتامادية الصوتية التي يمكن اعتمادها لتكملة أساليب عزل الصوت التقليدية لتصميم المباني بكفاءة صوتية. ثم يتم شرح أداء هذه المواد الميتامادية من خلال كثافتها السلبية المميزة، ومرونة الكتلة أو الهيكل الدقيق المتكرر أو المتردد محليًا. كما تمتد المراجعة لتشمل المواد الميتامادية الصوتية الشفافة للهواء التي يمكن استخدامها لعزل الصوت في تهوية المباني. أخيرًا، يتم مناقشة الآفاق والتحديات المتعلقة باعتماد المواد الميتامادية الصوتية في عزل المباني. بشكل عام، يمكن أن تؤدي المواد الميتامادية الصوتية القابلة للتعديل والمتعددة الوظائف عند دمجها بعناية في عزل الصوت في المباني إلى راحة صوتية كبيرة، وتوفير المساحة، وخفة الوزن.

1. المقدمة

هندسة الصلابة التي تسمح بتصميمها في مجموعة متنوعة من المواد السائبة المناسبة [2].

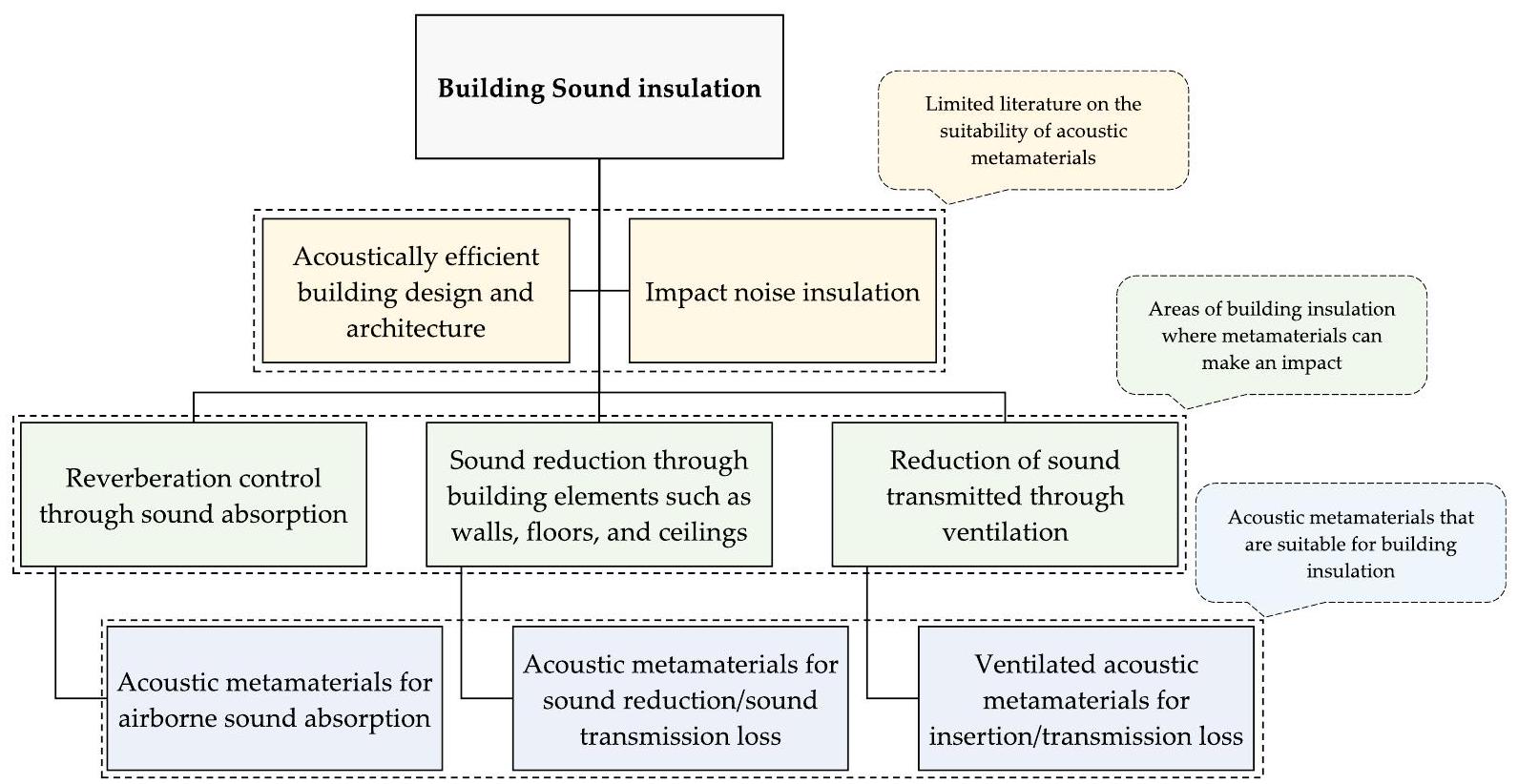

2. الجوانب الأساسية للمواد الميتامادية الصوتية في تصميم المباني

2.1. أهمية المواد الميتامادية الصوتية

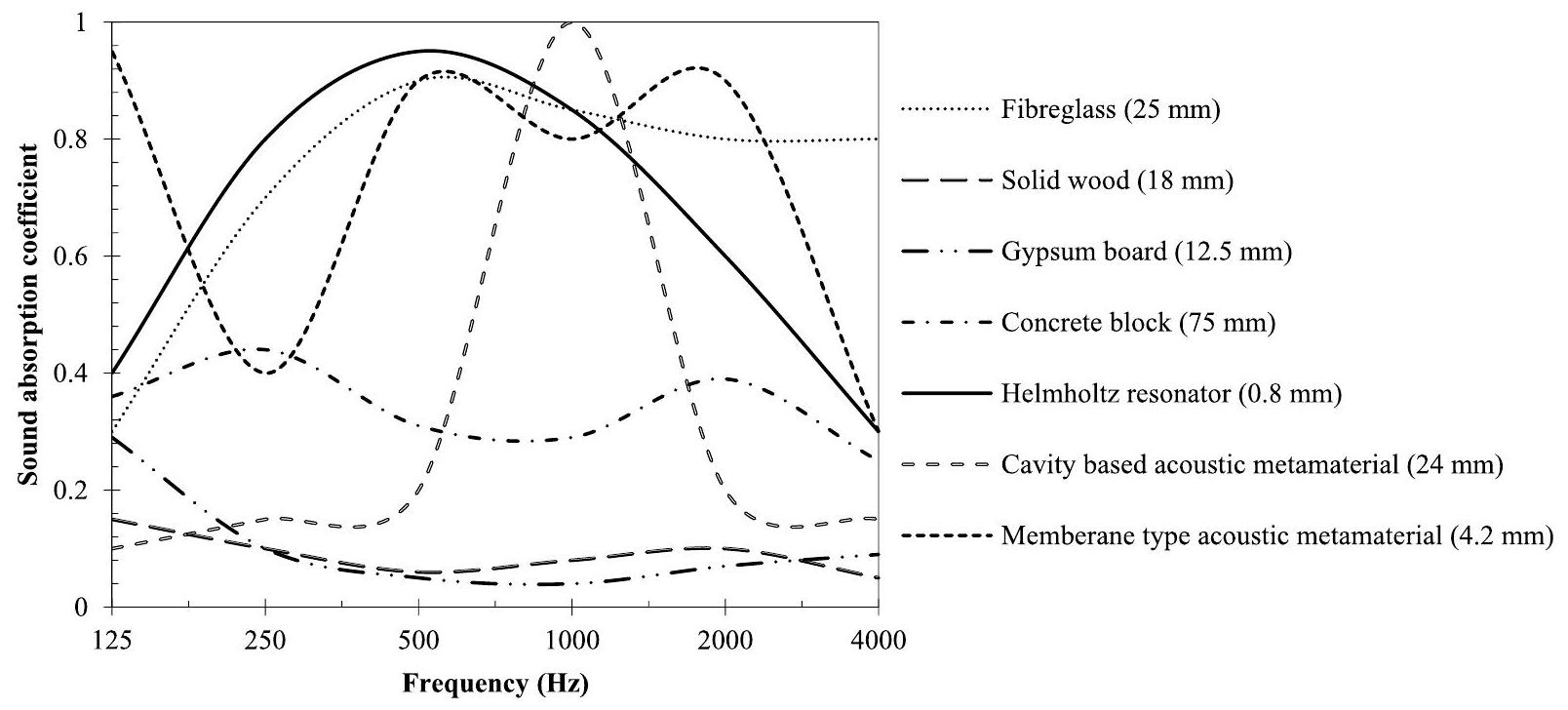

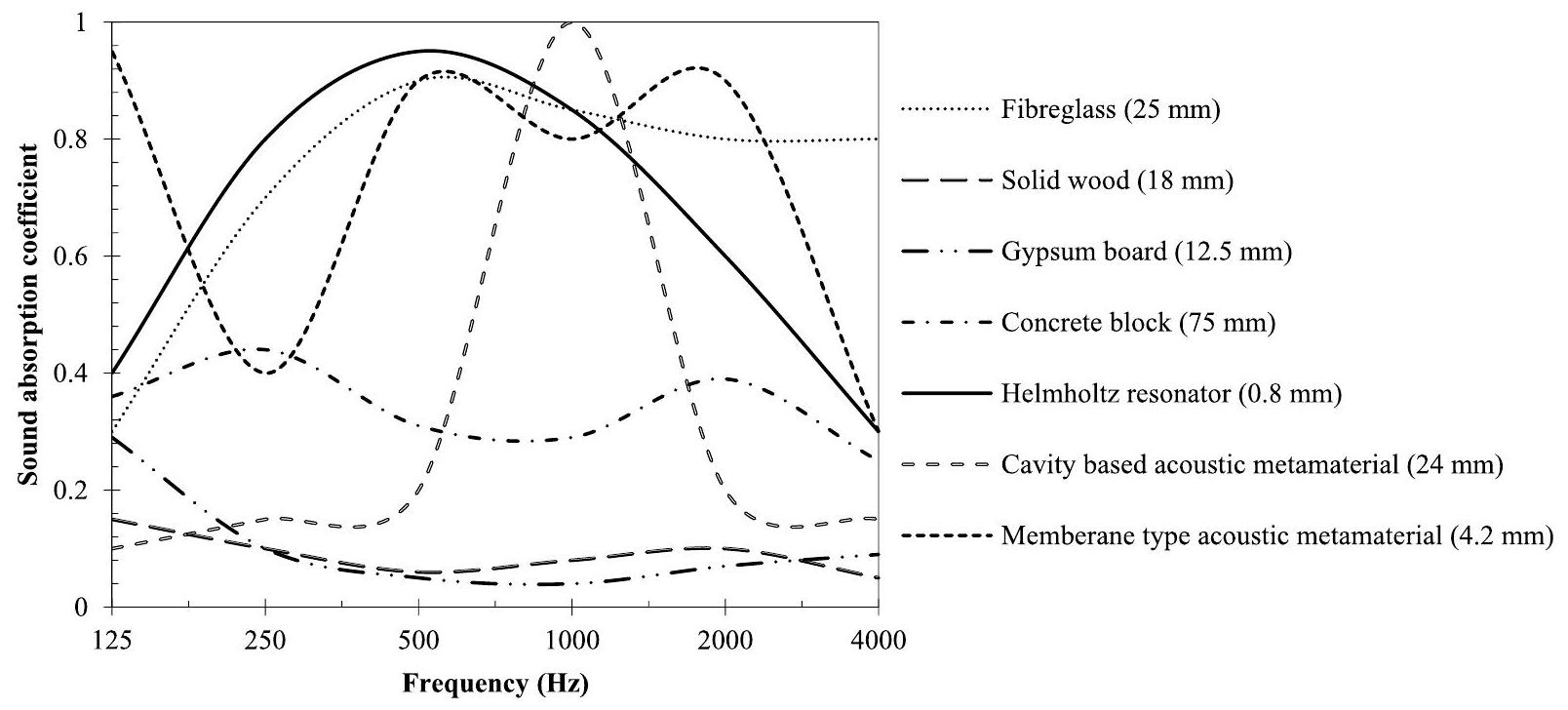

2.2. امتصاص الصوت

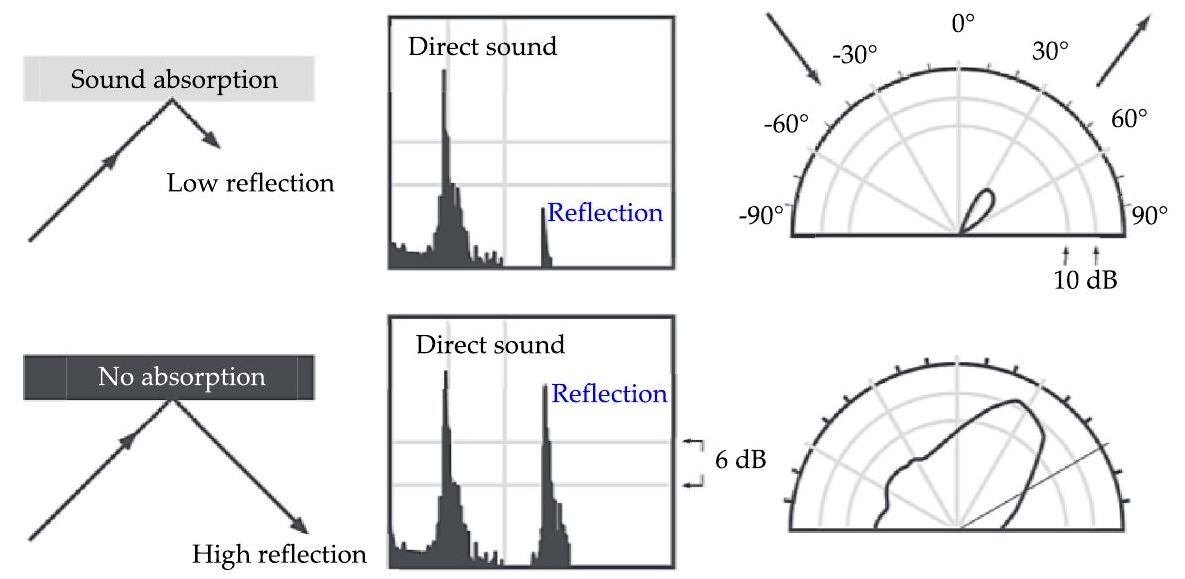

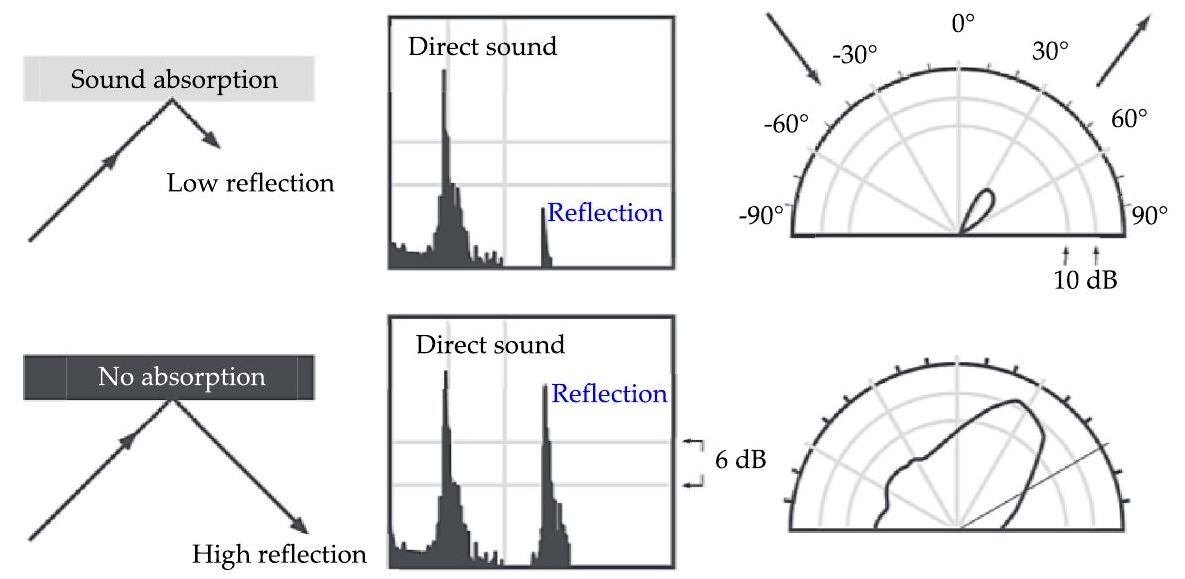

تحددها الخصائص الصوتية للهيكل، وتسمى الأسطح التي تمتص الصوت بشكل فعال بممتصات الصوت الجيدة. يتم تصوير تمثيل بصري لبيئة المبنى مع وبدون علاجات امتصاص الصوت في الشكل 2، موضحًا الجوانب الزمنية والمكانية للصوت داخل مساحة معينة.

استجابة زمنية استجابة مكانية

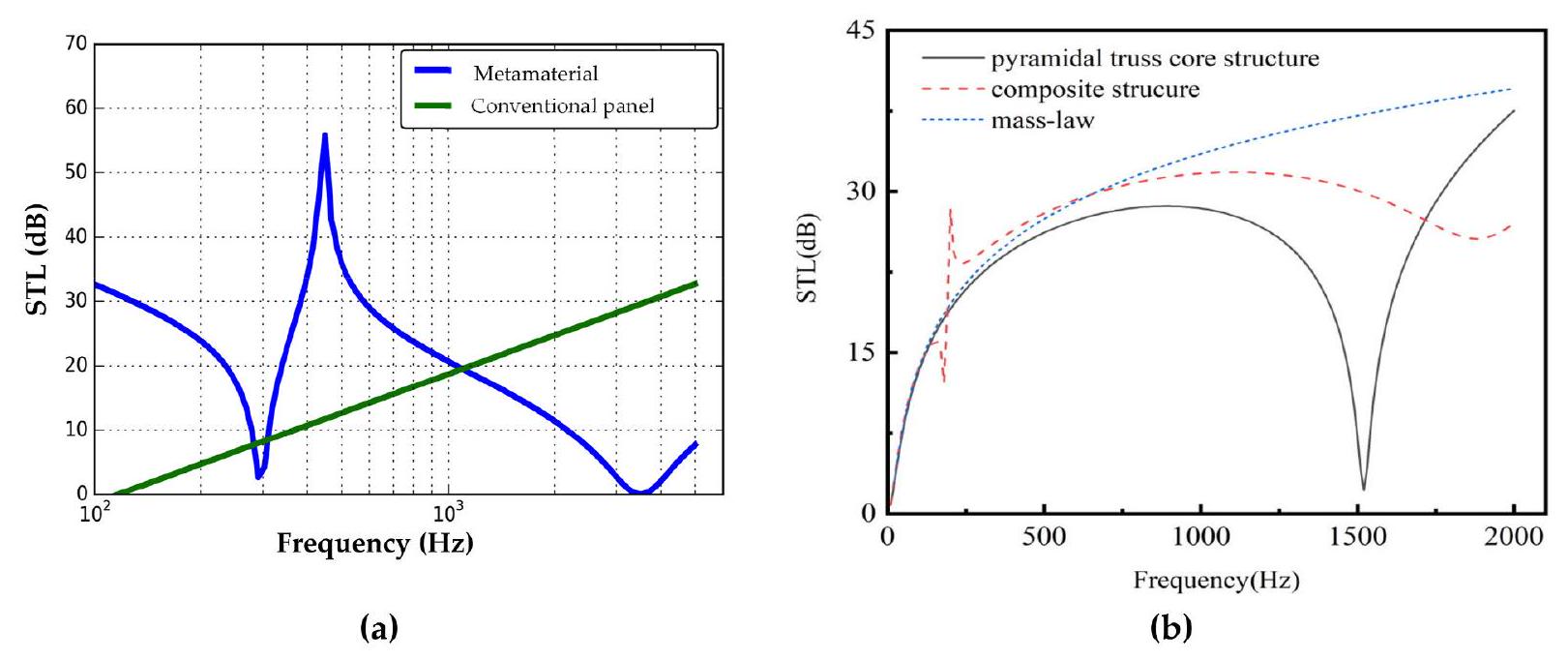

2.3. عزل الصوت أو تقليل الصوت

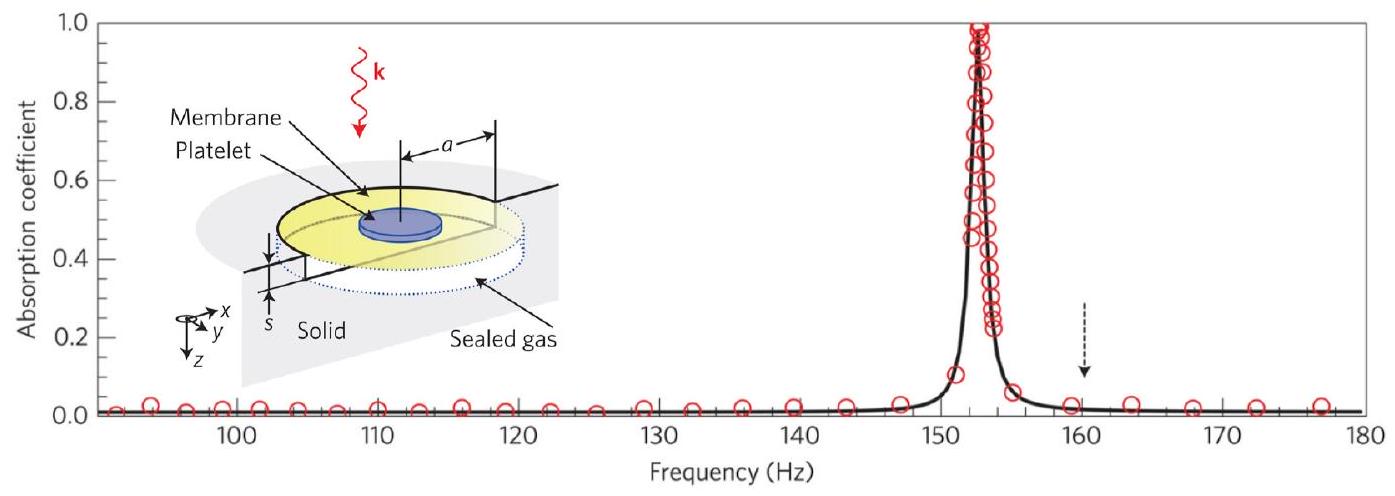

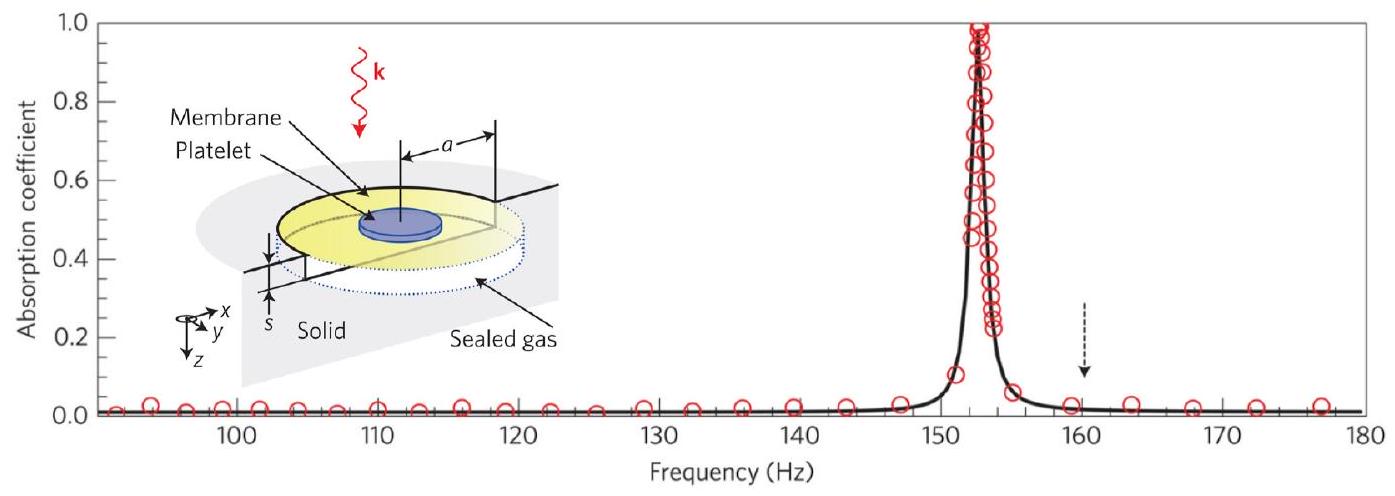

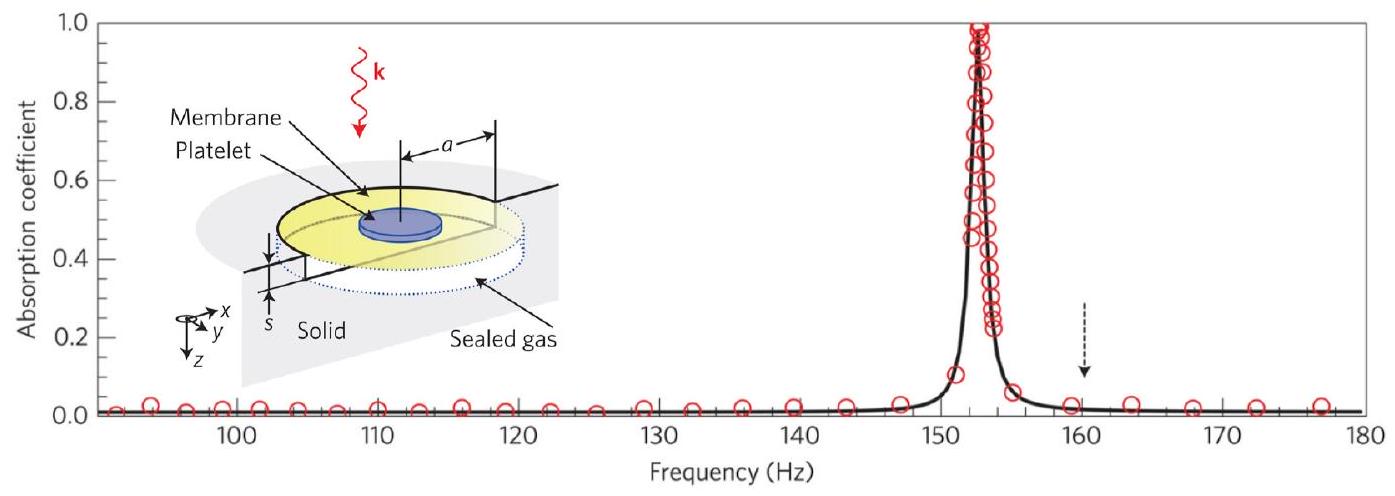

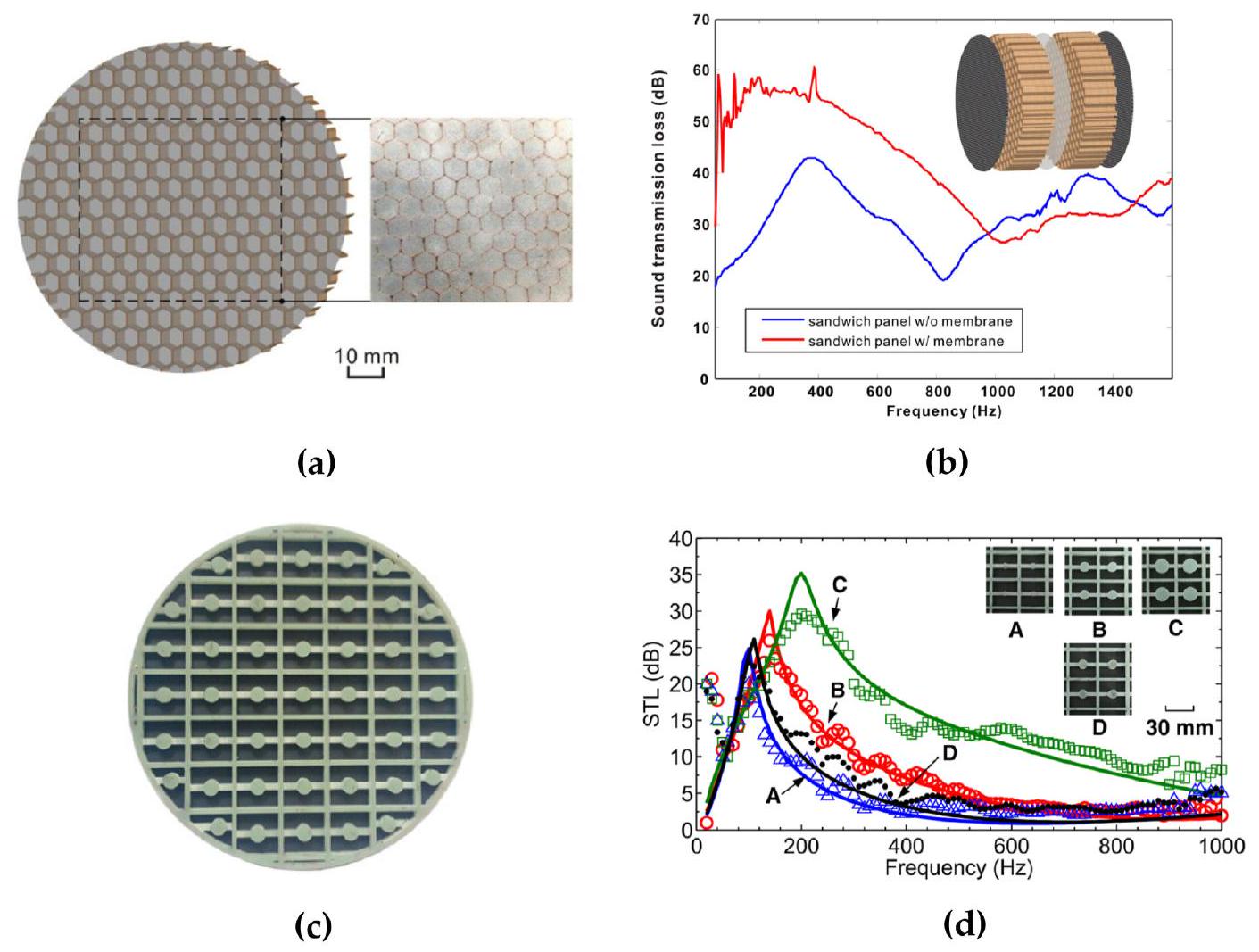

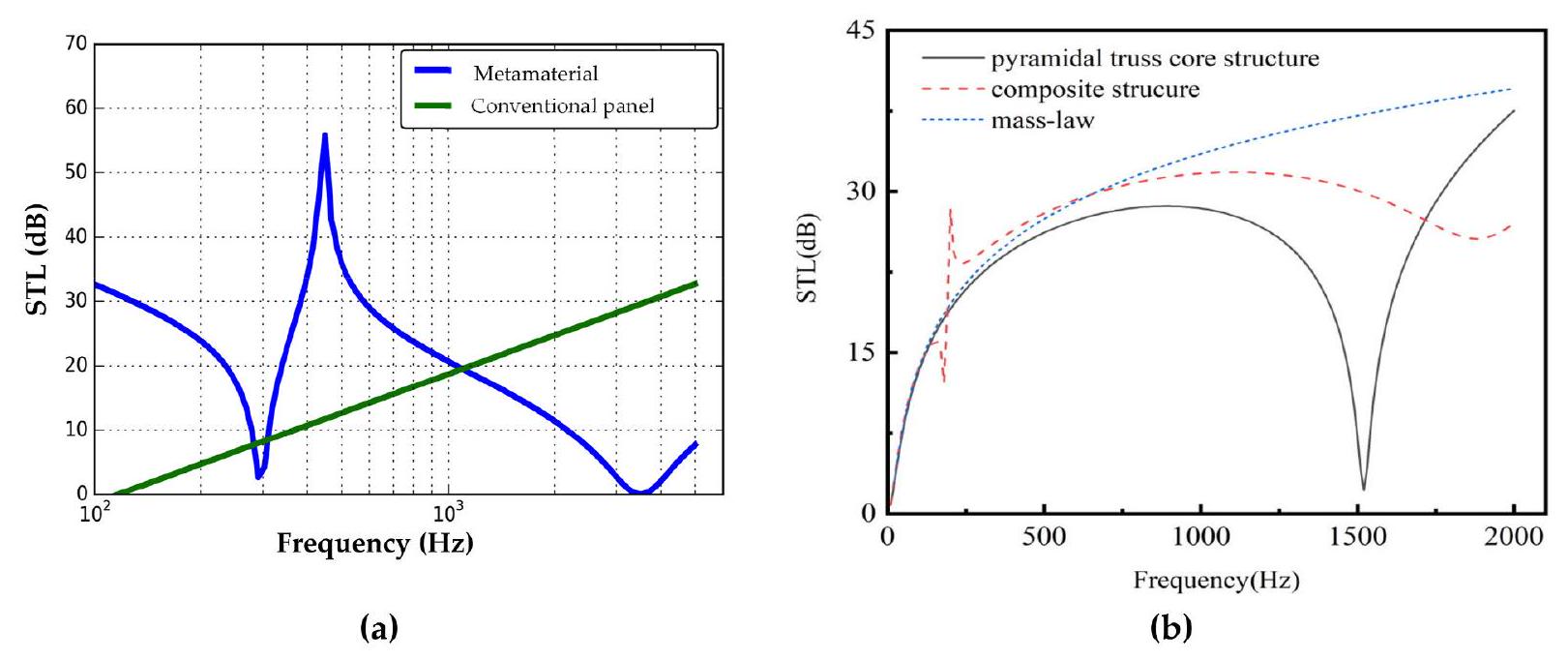

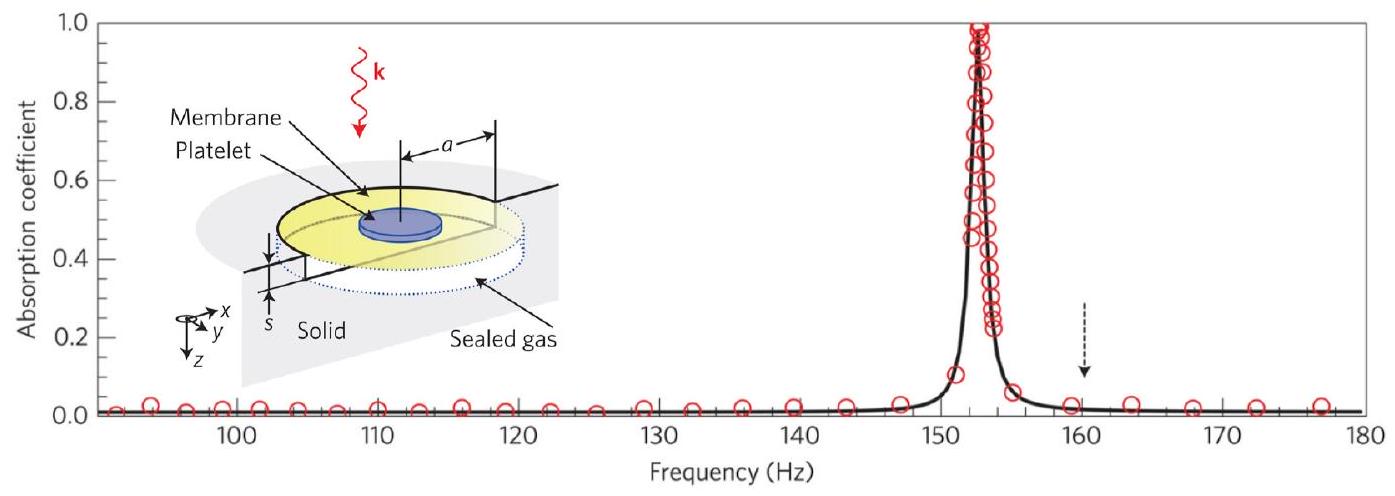

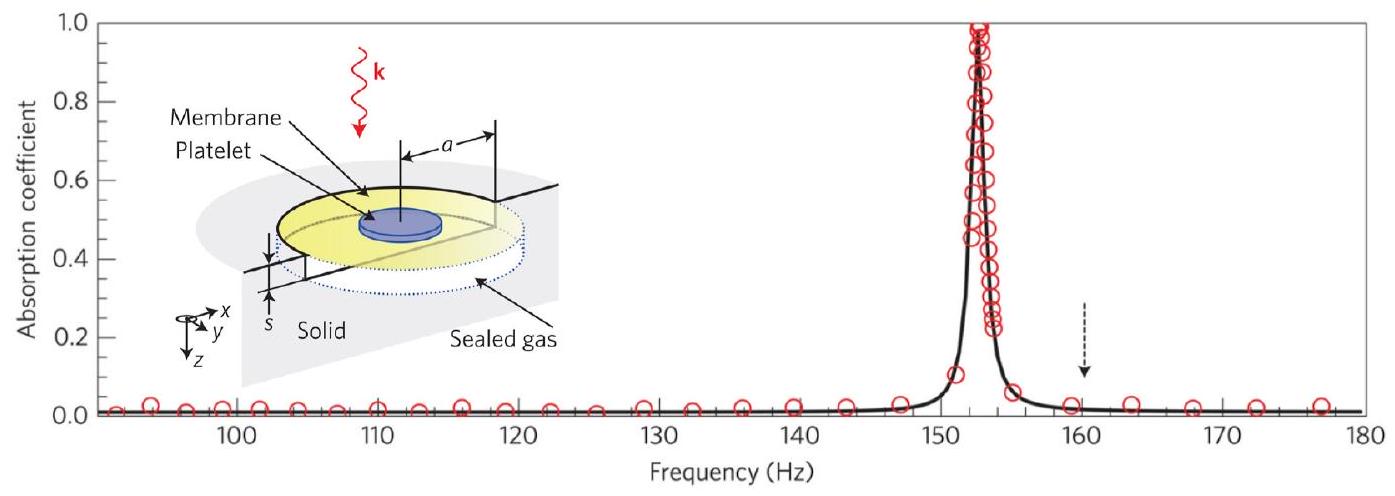

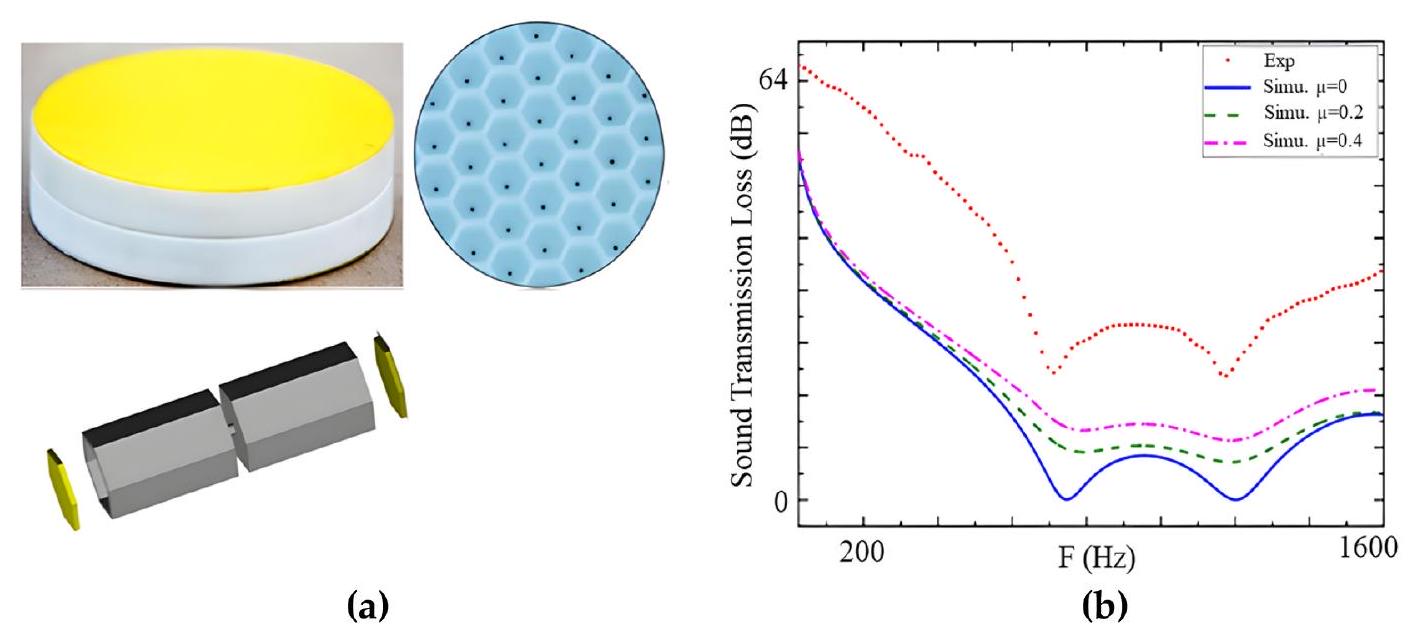

من المتوقع أن تصبح الهياكل ذات الأغشية المحاطة والألواح الخيار القياسي لتقليل الاهتزازات والضوضاء ذات التردد المنخفض في الهندسة العملية بسبب فوائدها، والتي تشمل تقليل السماكة وكثافة السطح المنخفضة. في المواد المركبة ذات الألواح الرقيقة، غالبًا ما توضع الثقوب أو الأعمدة على لوح مستمر بسماكة قابلة للتغيير وثقوب أو أعمدة بأحجام وأشكال مختلفة. على عكس المواد المركبة ذات الألواح، تستخدم المواد المركبة ذات الأغشية دائمًا إطارًا لتقسيم الخلايا الفردية بينما يتم تنظيم كتلة واحدة أو أكثر على الغشاء. يجب إعطاء إجهاد أولي للغشاء لدعم انتشار الاهتزازات، حيث أن صلابة الغشاء غير كافية لمقاومة جاذبيته الخاصة.

2.4. امتصاص الصوت وتقليل الصوت بشكل نشط وسلبي

3. ميزات المواد الميتامادية الصوتية لتطبيقات البناء

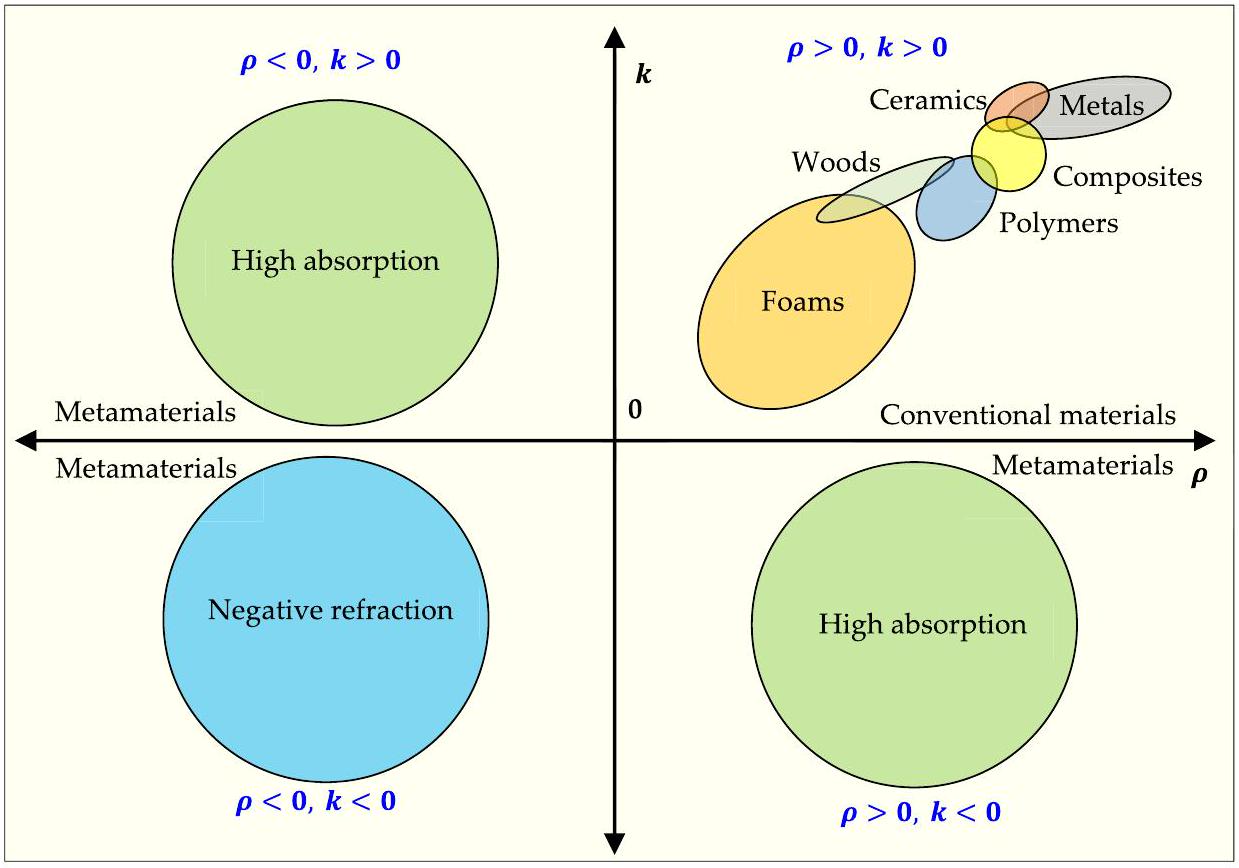

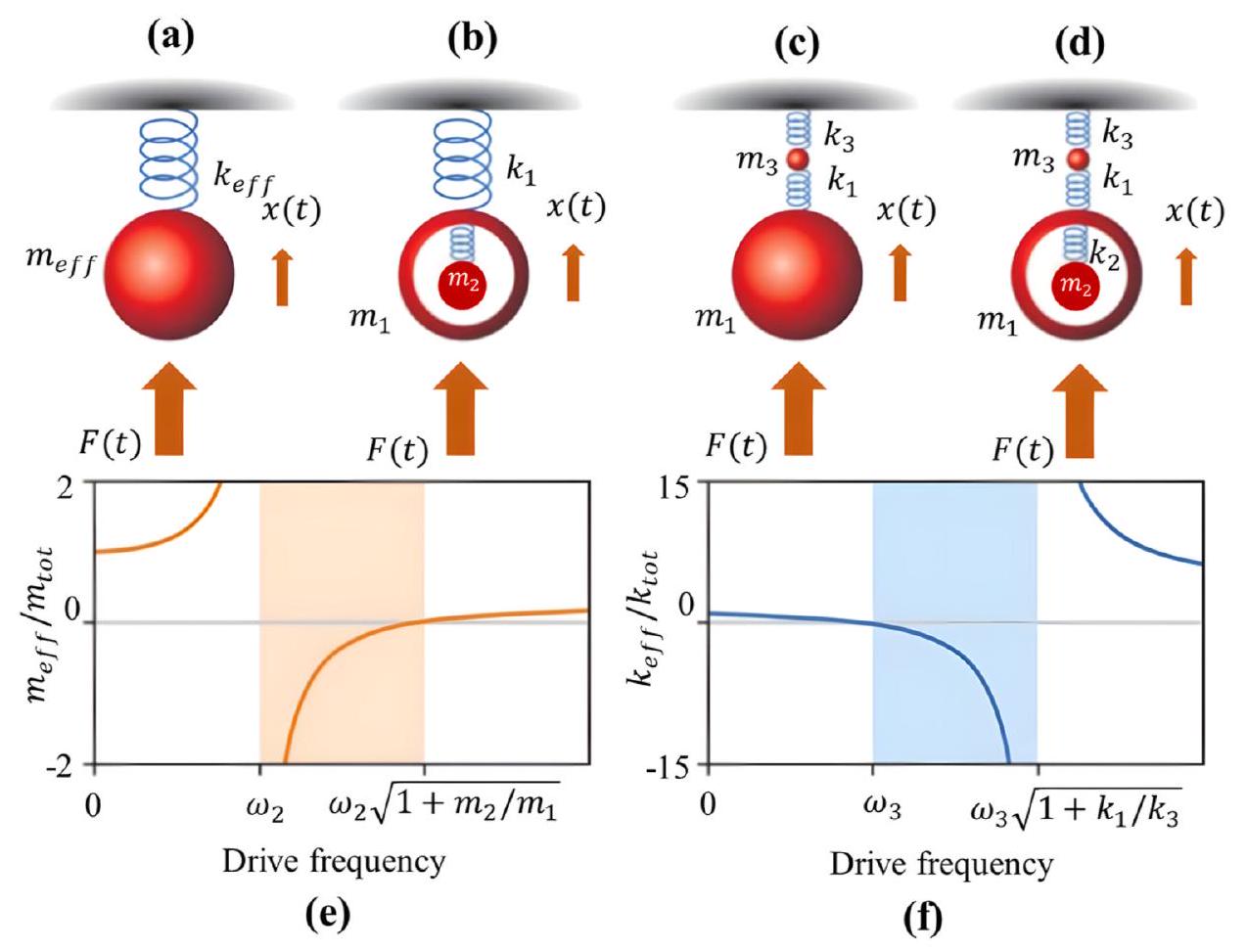

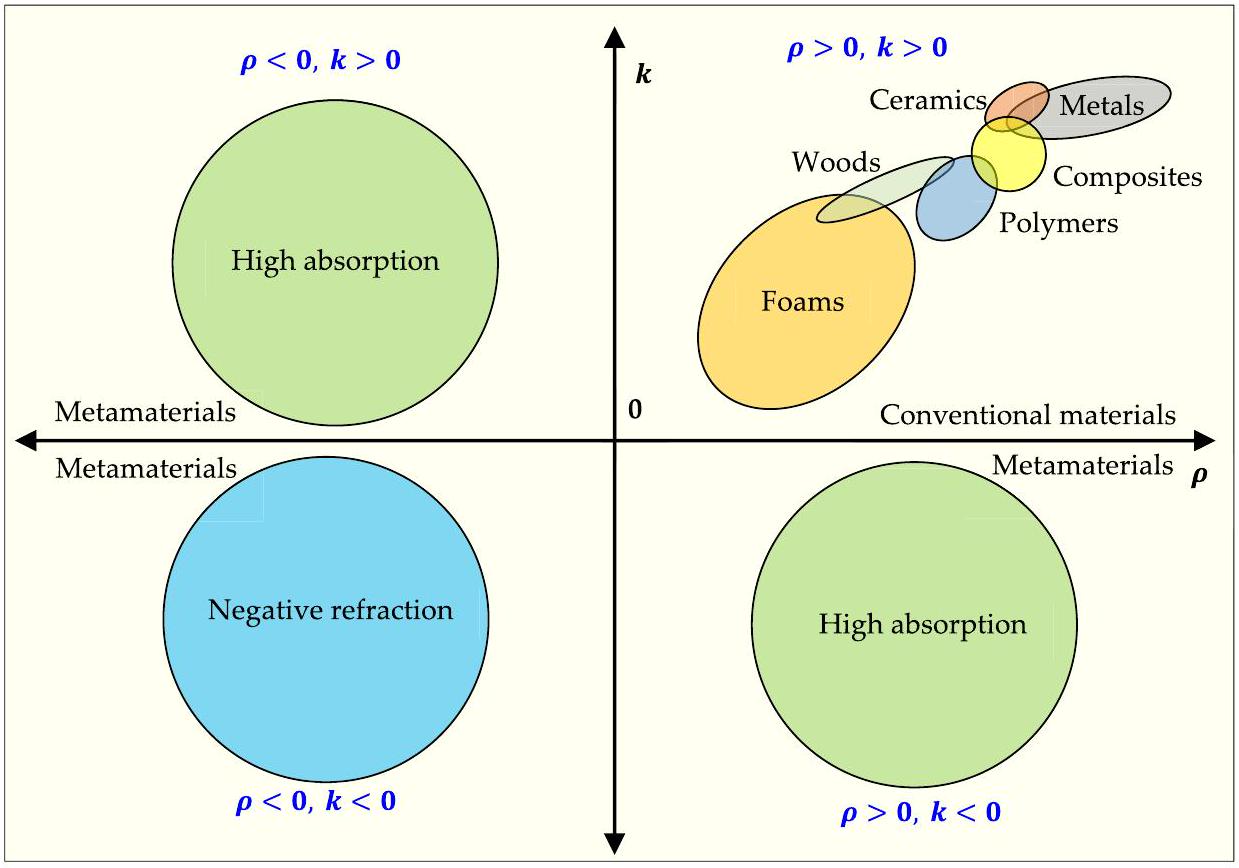

3.1. مفاهيم كثافة الكتلة السلبية ومعامل الحجم

التي تميز قابلية انضغاط المادة. رياضيًا، يتم تعريف معامل الحجم على أنه نسبة التغير في الضغط إلى التغير النسبي في الحجم. المواد ذات معامل الحجم العالي أقل قابلية للانضغاط، مما يعني أنها تقاوم التغيرات في الحجم بشكل أكثر فعالية. عادةً ما تكون السوائل والمواد الصلبة ذات معاملات حجم غير سالبة، بينما يمكن أن تحتوي الغازات على معاملات حجم سالبة تحت ظروف معينة. إنه معلم رئيسي في المواد الميتامادية الصوتية لأنه يمكن استخدامه للتحكم في سرعة واتجاه موجات الصوت. من خلال ضبط معامل الحجم لمادة ما، من الممكن التلاعب في انتشار موجات الصوت. معًا،

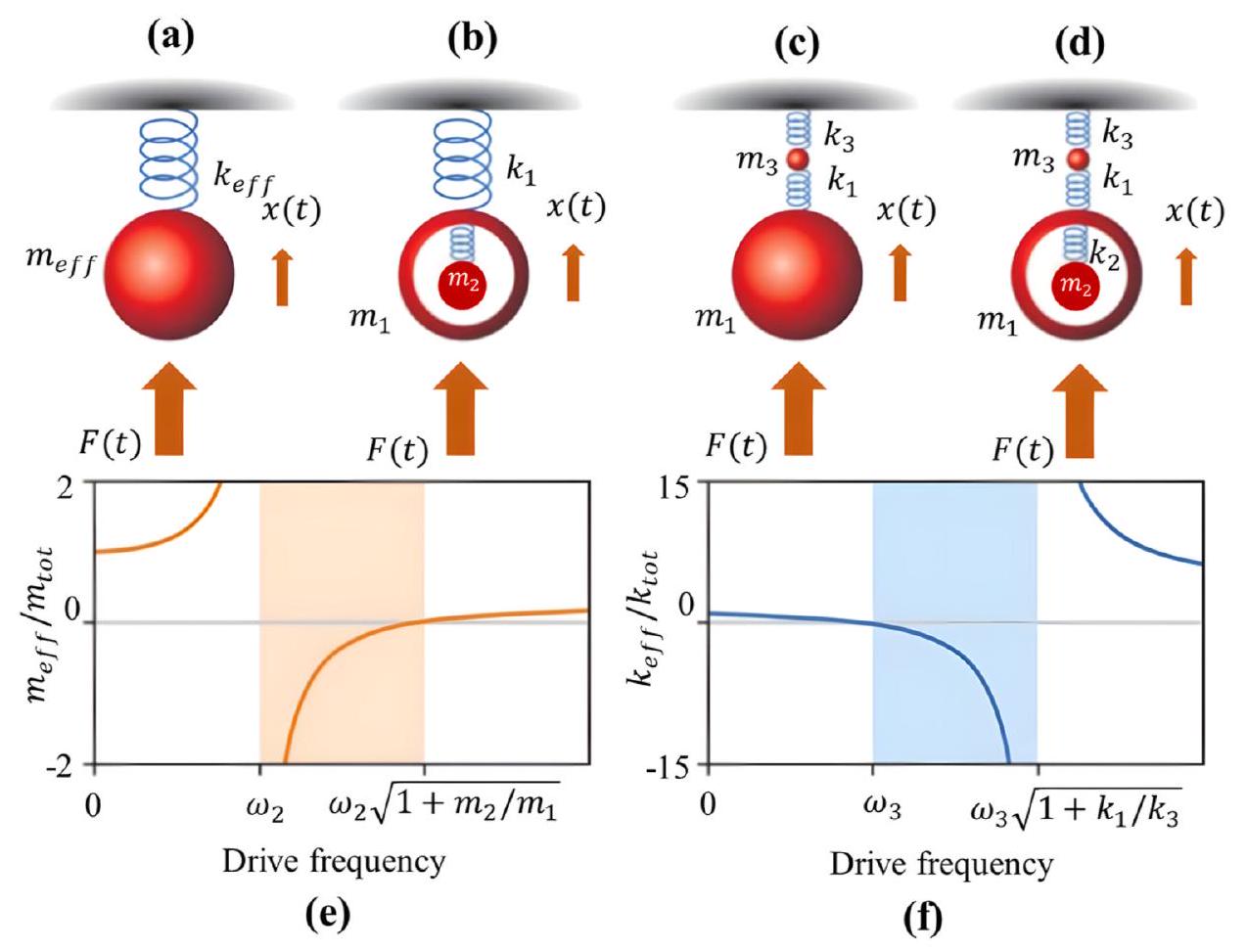

3.2. البنية الميكروية الديناميكية

مواد ميتا صوتية بخصائص مصممة. يبرز الشكل الإمكانية لتحقيق الكتلة السلبية والصلابة، مما يمهد الطريق لتطبيقات مبتكرة في التحكم في الصوت وتلاعب الموجات ضمن مجال المواد الميتا الصوتية.

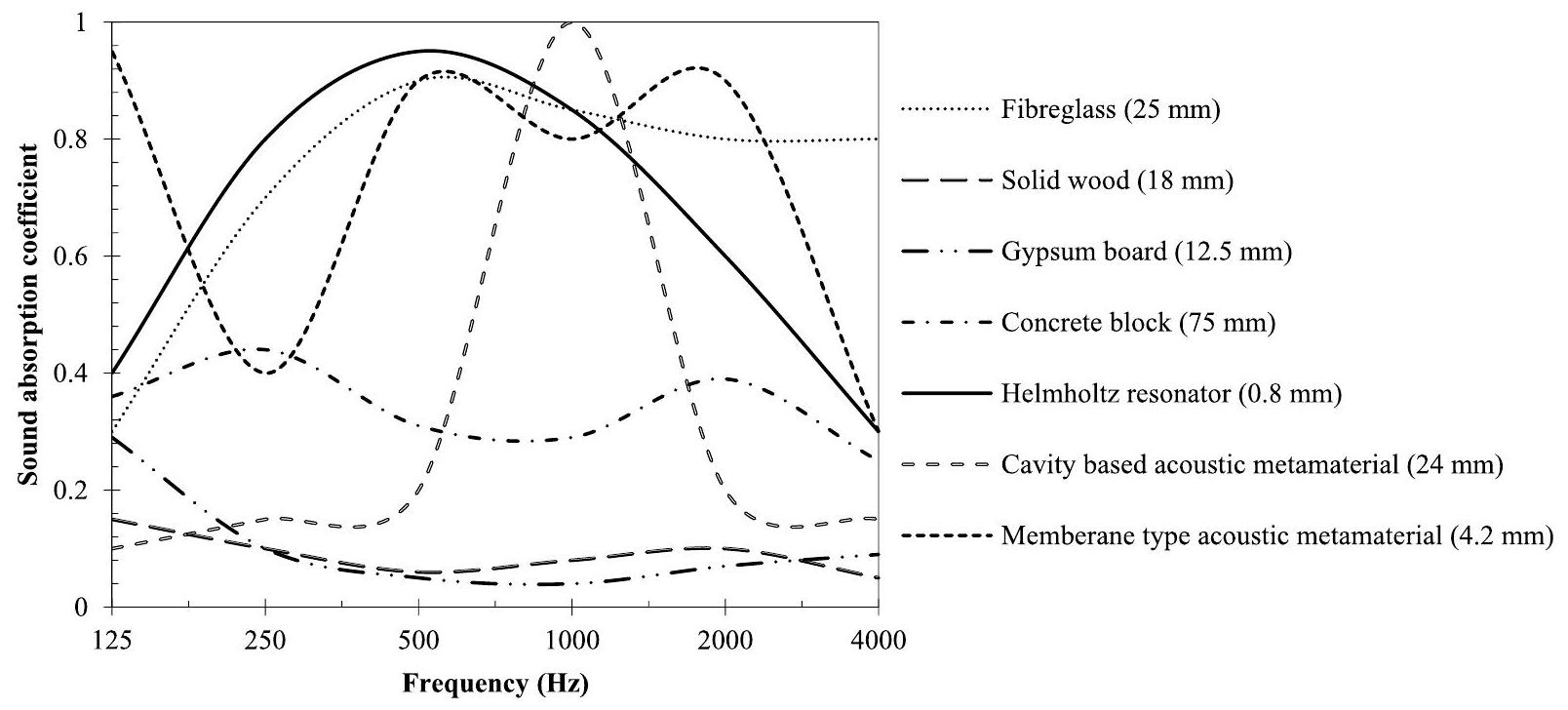

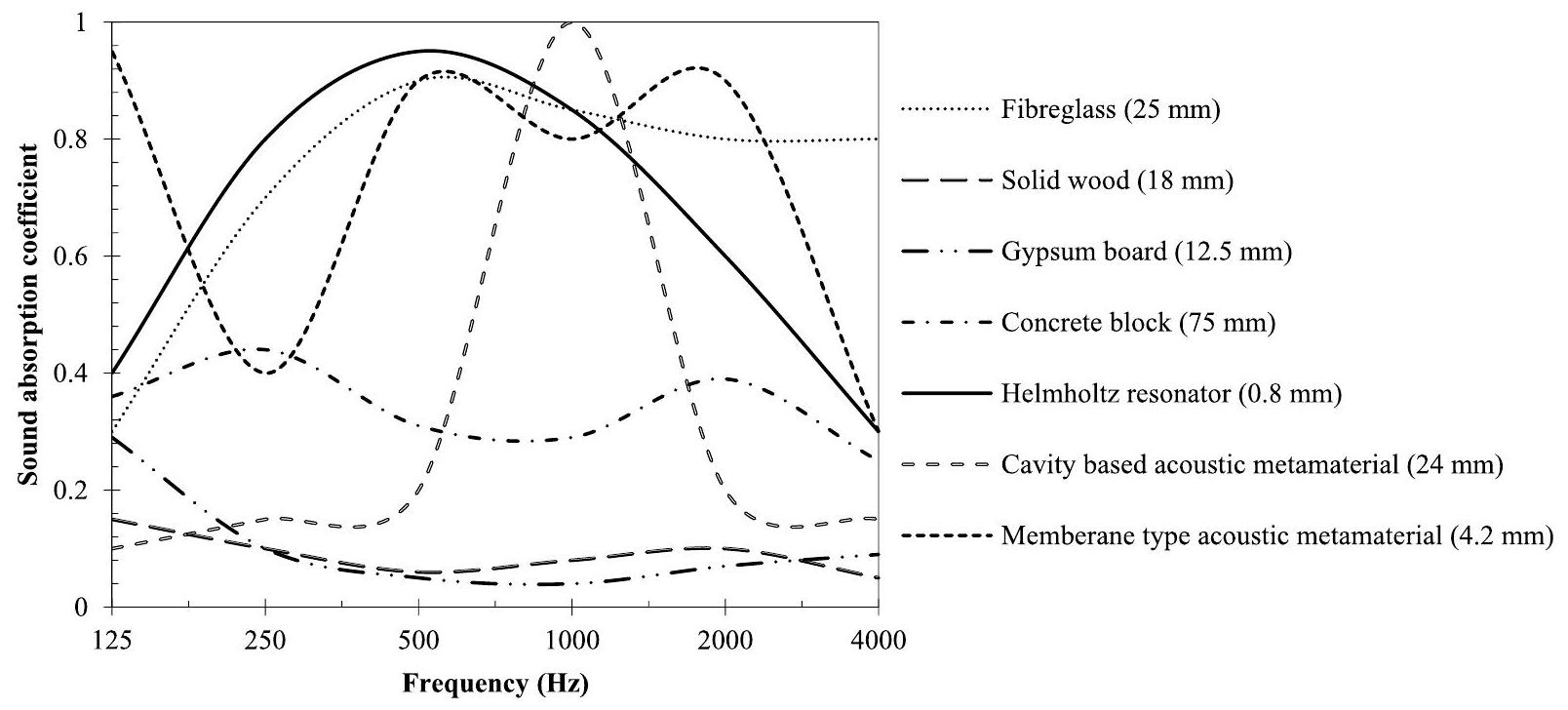

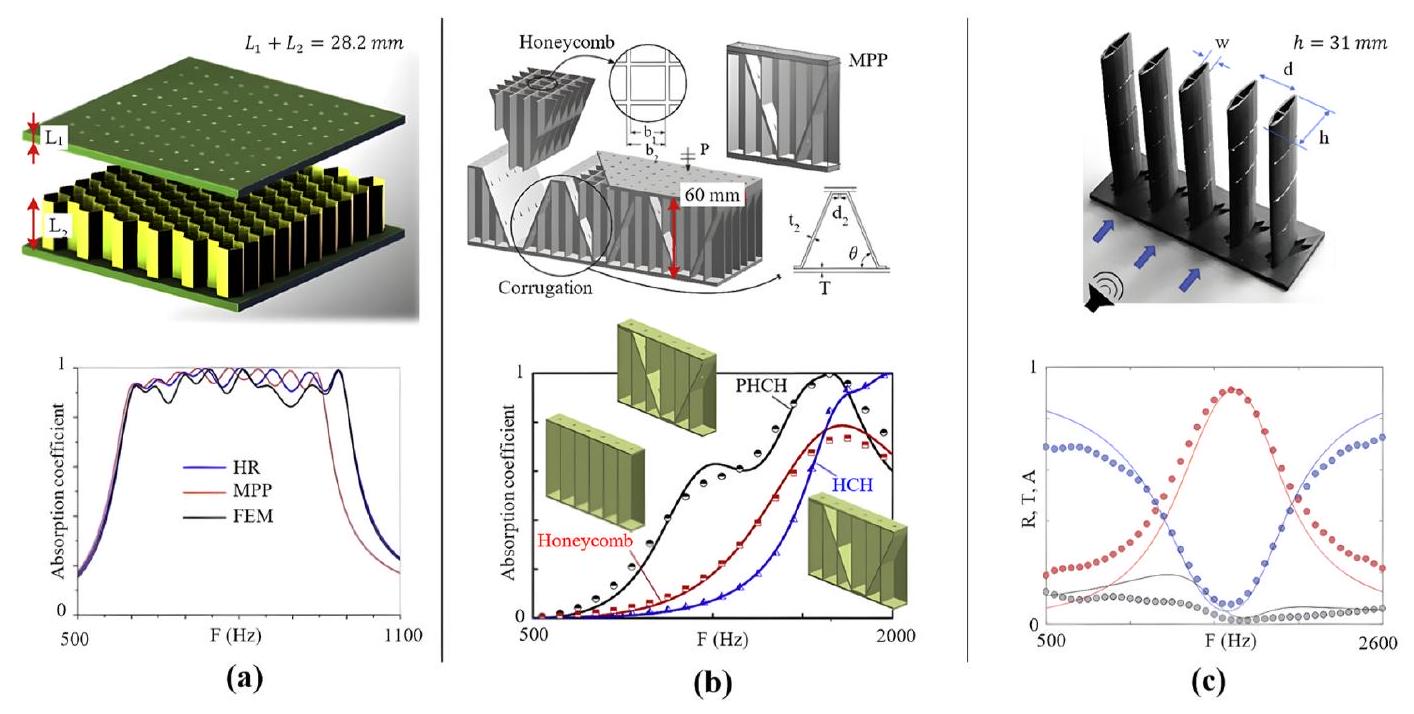

4. المواد الميتا الصوتية لامتصاص الصوت

4.1. هندسة من نوع هيلمهولتز

مركزات الكتلة داخل هيكل مسامي، مما أدى إلى استثنائية

4.2. هندسة من نوع الغشاء

مواد ميتا صوتية تقدم امتصاص صوت يعتمد على التردد العالي مناسب للتطبيق في بناء الصوتيات [5].

| المادة | الحجم (مم) | التردد (هرتز) | المرجع. |

| نواة مموجة على شكل خلية نحل مدمجة مع تجاويف رنين | 60 | 2000 | [53] |

| قناة موجية تجمع بين الأنابيب ومواد MPP الميتا | 54 | 800-1000 | [71] |

| مواد ميتا صوتية تجمع بين فتحات هيلمهولتز | 50 | 130-170 | [72] |

| رنانات هيلمهولتز التي تتميز بألواح مثقبة دقيقة | 62 | 450-1360 | [73] |

| تجاويف رنين تتميز بالهلامات الهوائية | 42 | 600 | [74] |

| مواد ميتا تتميز بقنوات موجية متوازية | 17 | 600 | [75] |

| قنوات موجية ملتفة تتميز بميزات هندسية | 24 | 146-168 | [76] |

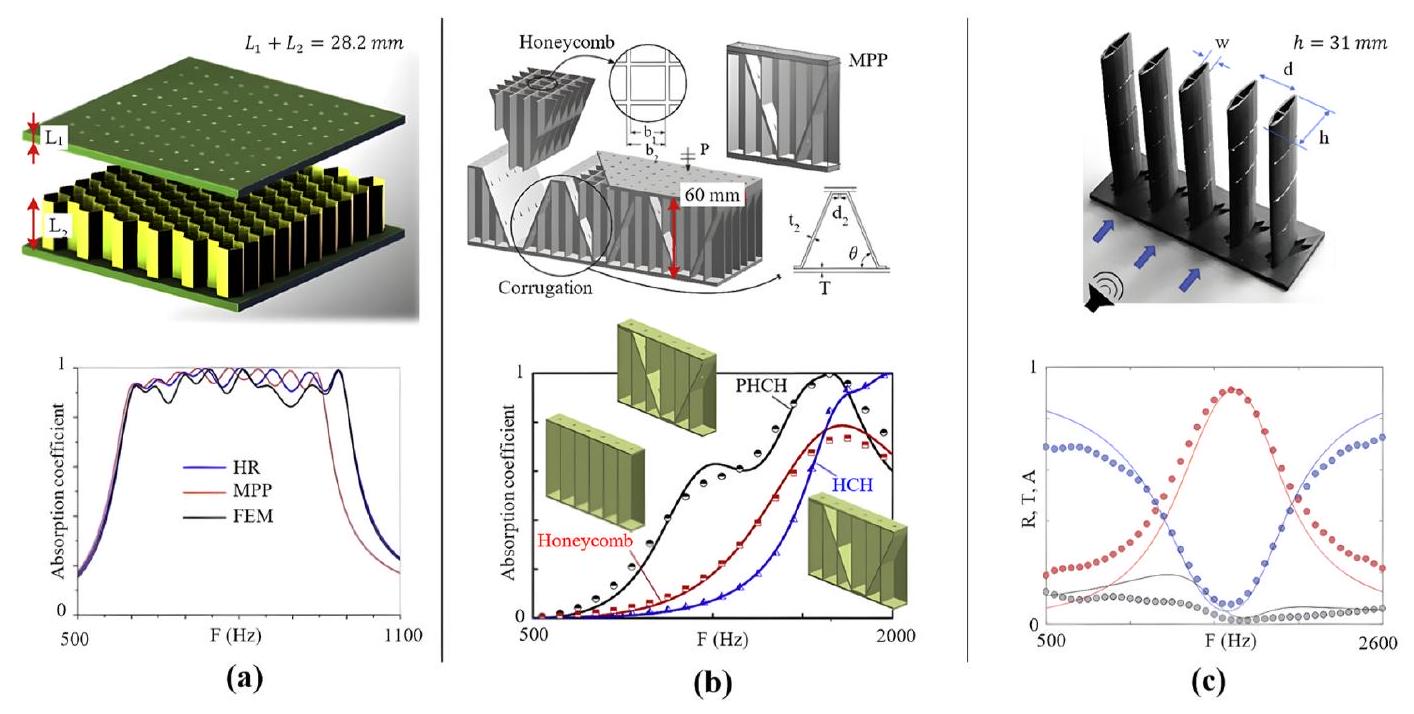

4.3. المواد الميتامادية الصوتية الملفوفة في الفضاء

الامتصاص المثالي، فإن تصنيعها على نطاق واسع لاستخدامها في acoustics المباني يمثل تحديًا. ومع ذلك، يمكن التغلب على ذلك من خلال استخدام المواد الميتامادية الصوتية ذات التواء الفضاء التي يمكن أن تحقق أيضًا امتصاصًا صوتيًا قريبًا من الكمال. وبالتالي، فإن الميزة الرئيسية لمادة الميتامادية الصوتية ذات التواء الفضاء مقارنة بالمواد القائمة على الأغشية هي سهولة توسيع نطاقها.

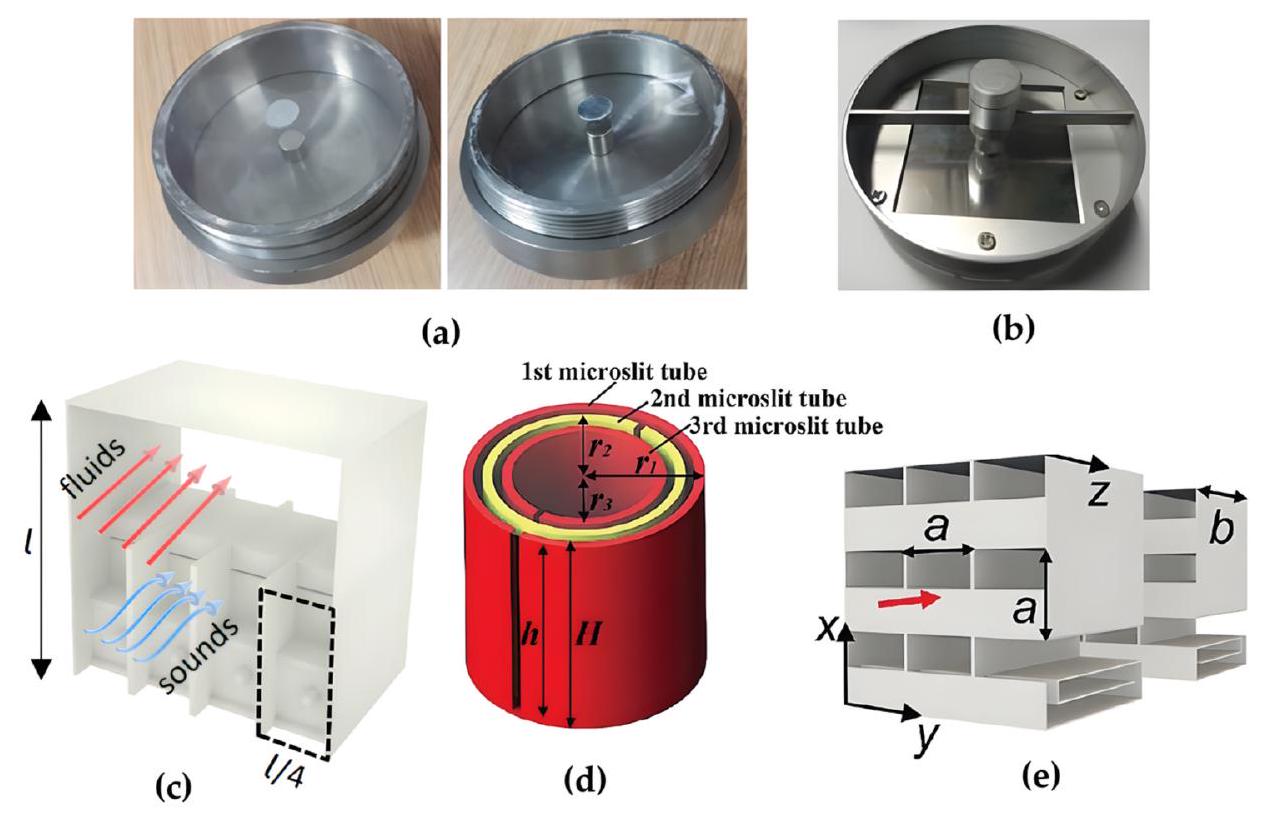

تظهر الشكل 11 أمثلة على المواد الميتامادية ذات التواء الفضاء التي تناسب من وجهة نظر acoustics المباني. بالنسبة لهذه المواد الميتامادية، يمكن تعديل الطول والحجم وحجم التواء الفضاء لتحقيق امتصاص شبه كامل في مجموعة من الترددات المسموعة. على سبيل المثال، فإن بنية التواء الفضاء في الشكل 11a التي طورها كاي وآخرون [75] قادرة تقريبًا

مادة صلبة.

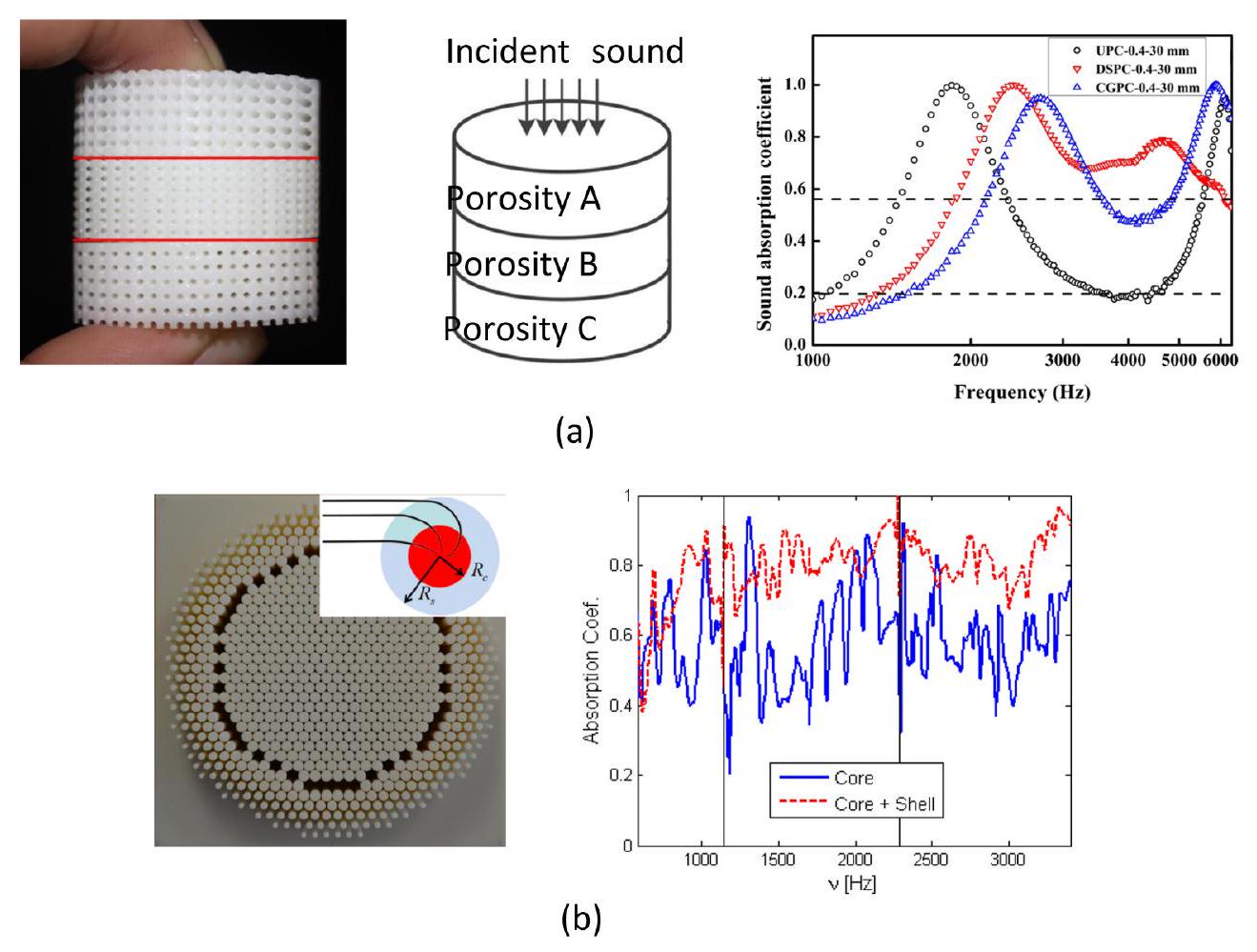

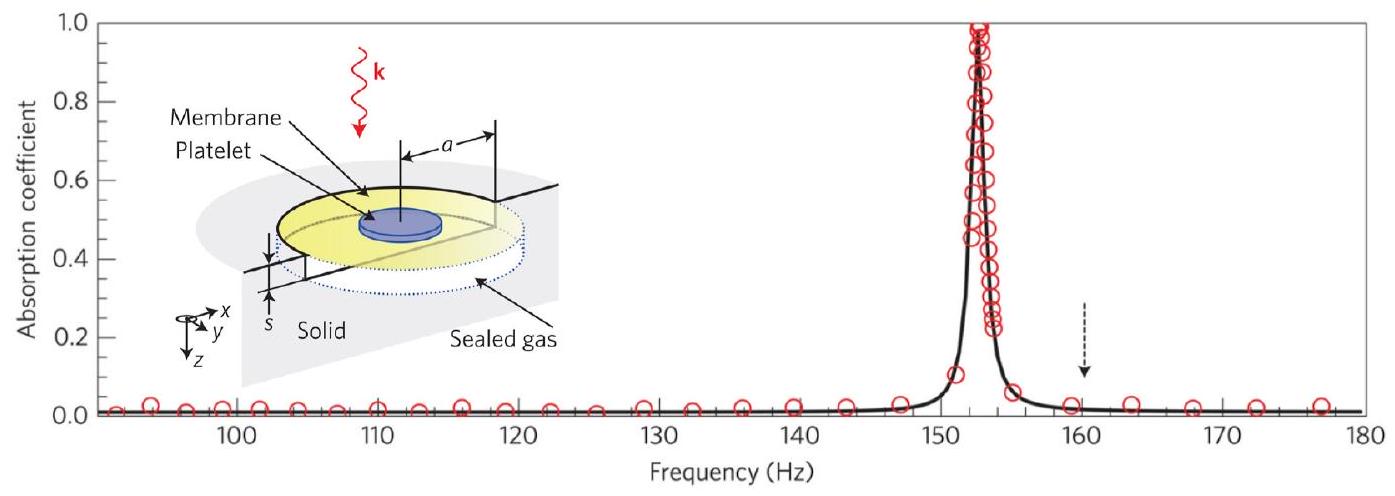

4.4. المواد الميتامادية الصوتية ذات معامل التدرج

4.5. المواد الميتامادية الصوتية القابلة للتعديل

5. المواد الميتامادية الصوتية لعزل الصوت

5.1. المواد الميتامادية المسامية المرنة

فعاليته في تطبيقات حواجز الصوت. تتضمن منهجية أخرى هياكل ميتا مسطحة مع تجاويف مرتبطة من خلال فتحة، والتي تم اختيارها لتحسين مؤشر تقليل الصوت. تشير النتائج إلى أن تأثير الترابط بين التجاويف المغلقة المرتبطة من خلال فتحة يمكن أن يؤثر على سلوك الصوت. وبالتالي، يمكن تعديل نصف قطر الفتحة لتحقيق أداء يعتمد على التردد. هذا التصميم لديه إمكانات كبيرة كحاجز ضوضاء [38،108] ويمكن أن يعالج المخاوف المتعلقة بالمواد الميتامادية. هذه الأمثلة توضح كيف يمكن استخدام المواد الميتامادية الصوتية لإنشاء حواجز صوتية قابلة للتوسع مناسبة للإنتاج الضخم.

5.2. المواد الميتامادية الصوتية القابلة للتعديل

5.3. المواد الميتامادية الصوتية السلبية من نوع الغشاء

5.4. مواد ميتامادية صوتية على شكل لوحات

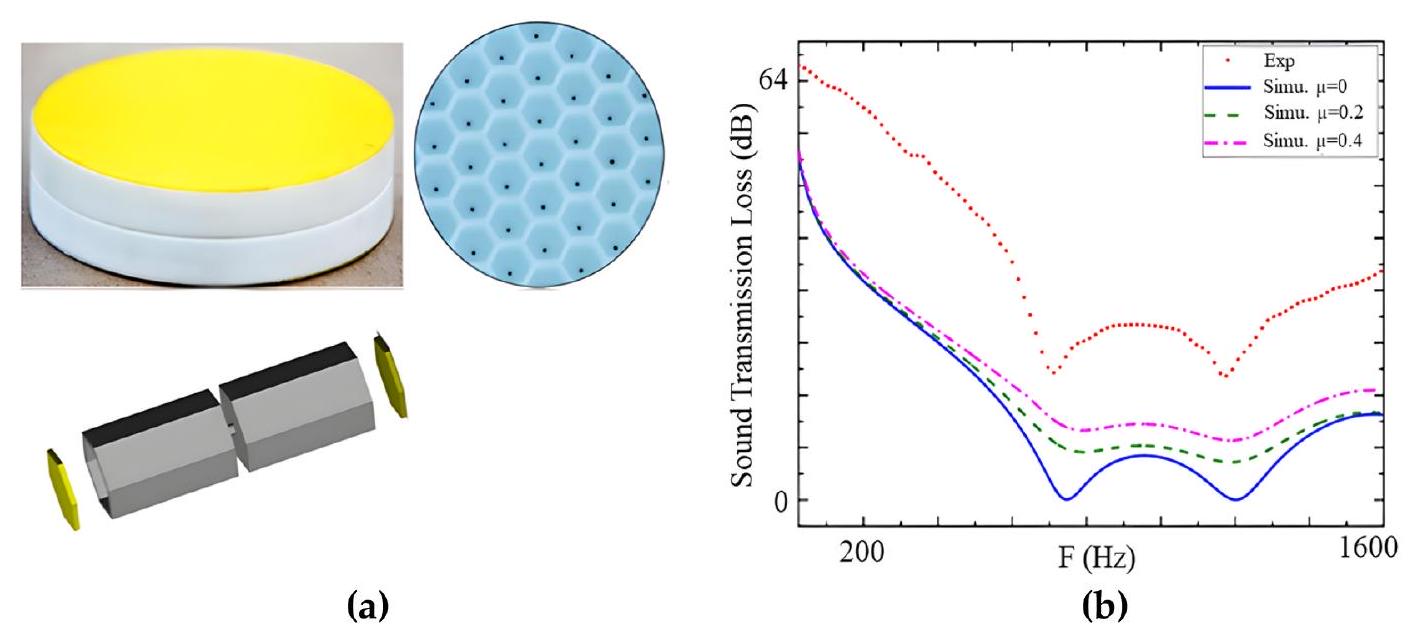

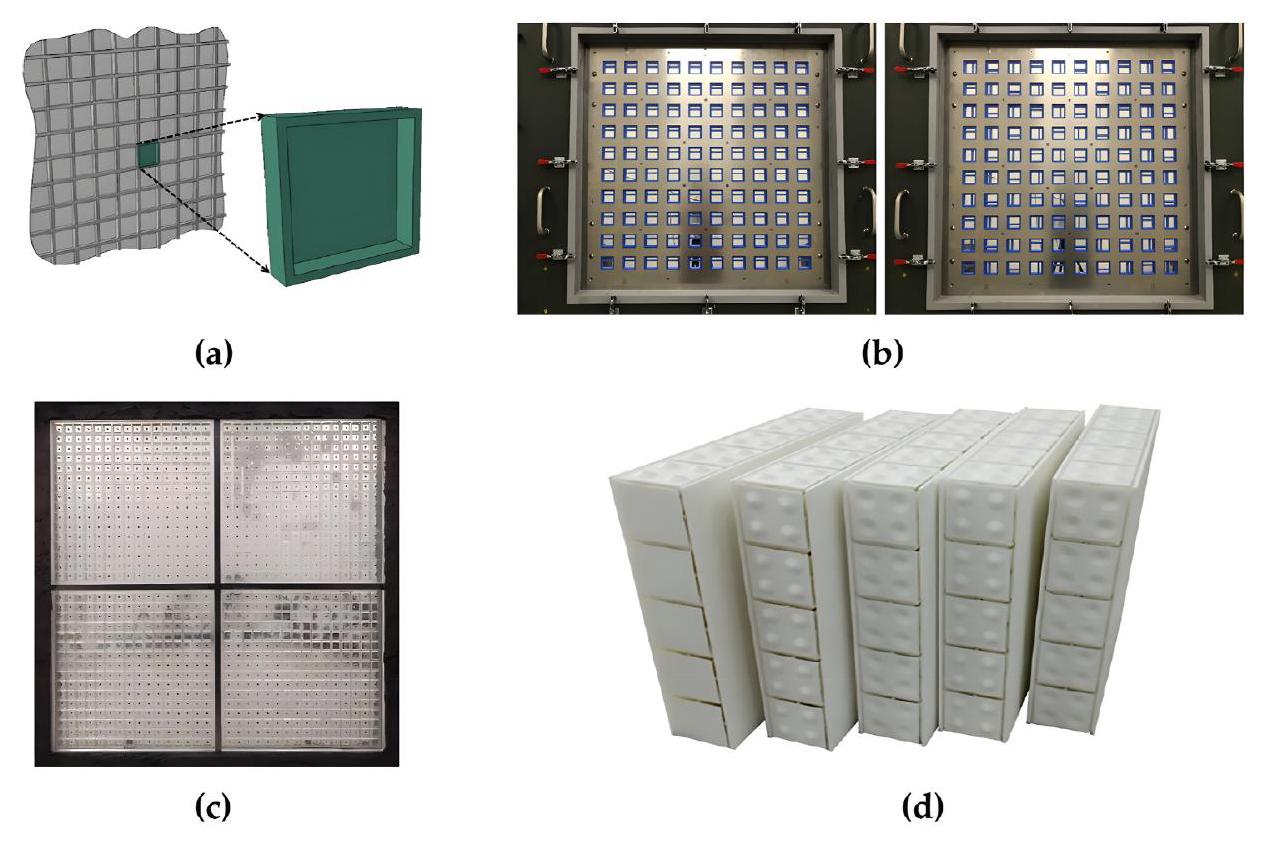

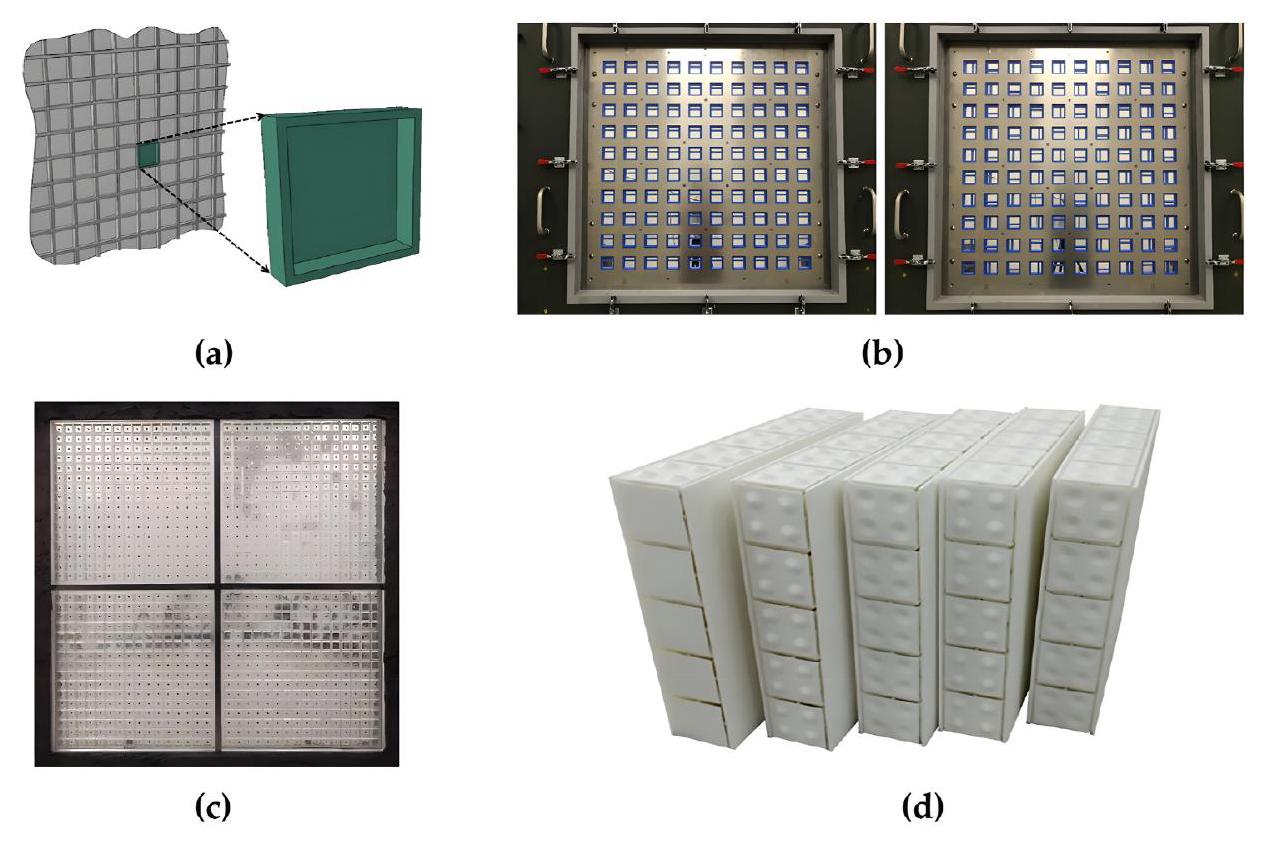

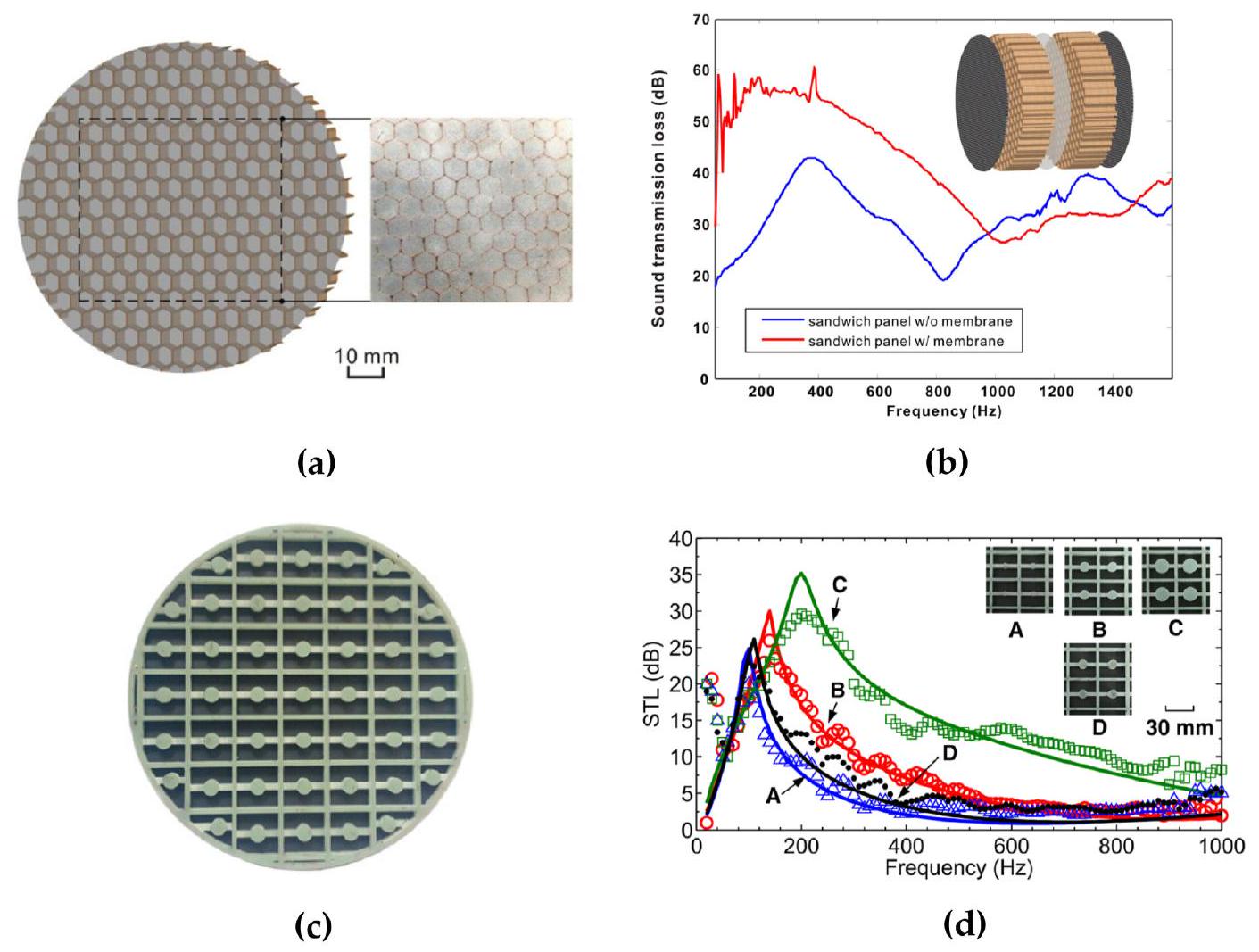

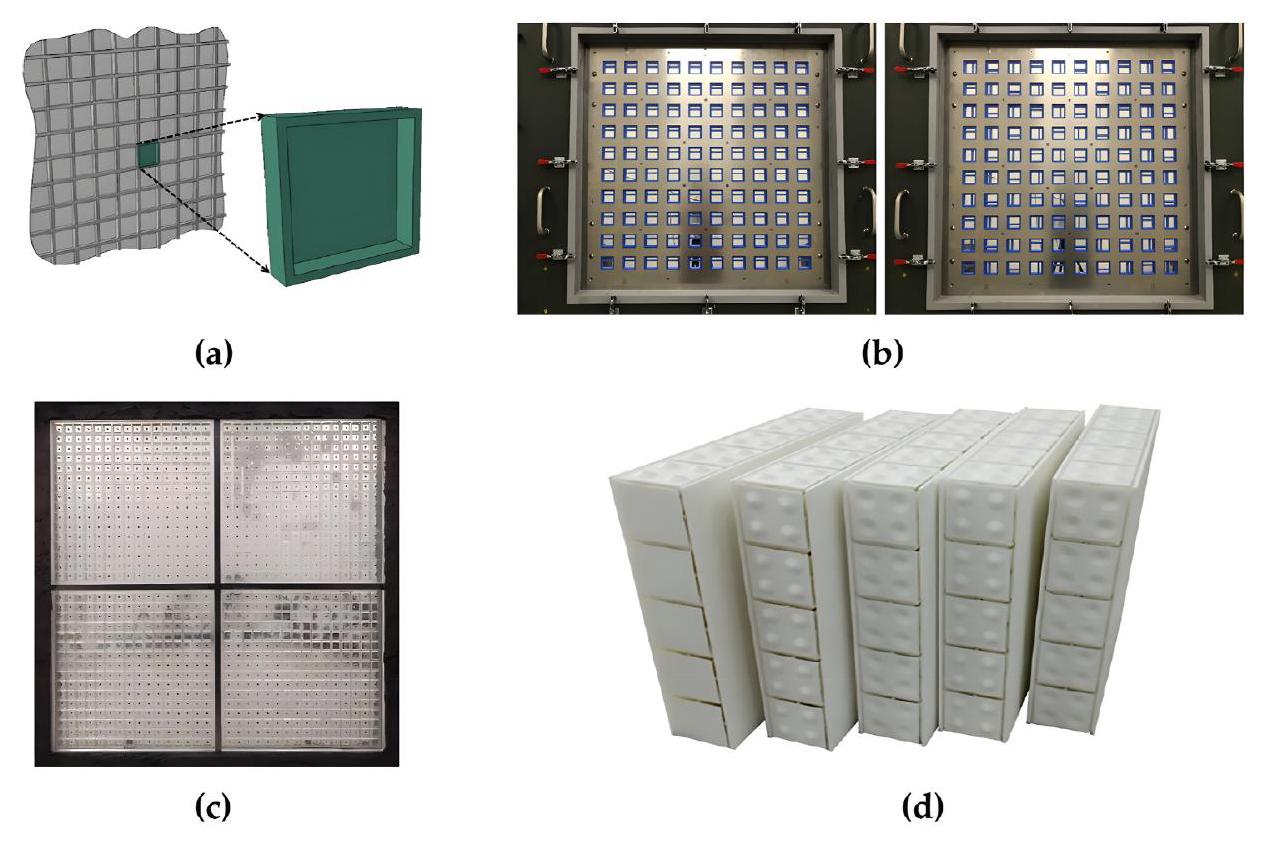

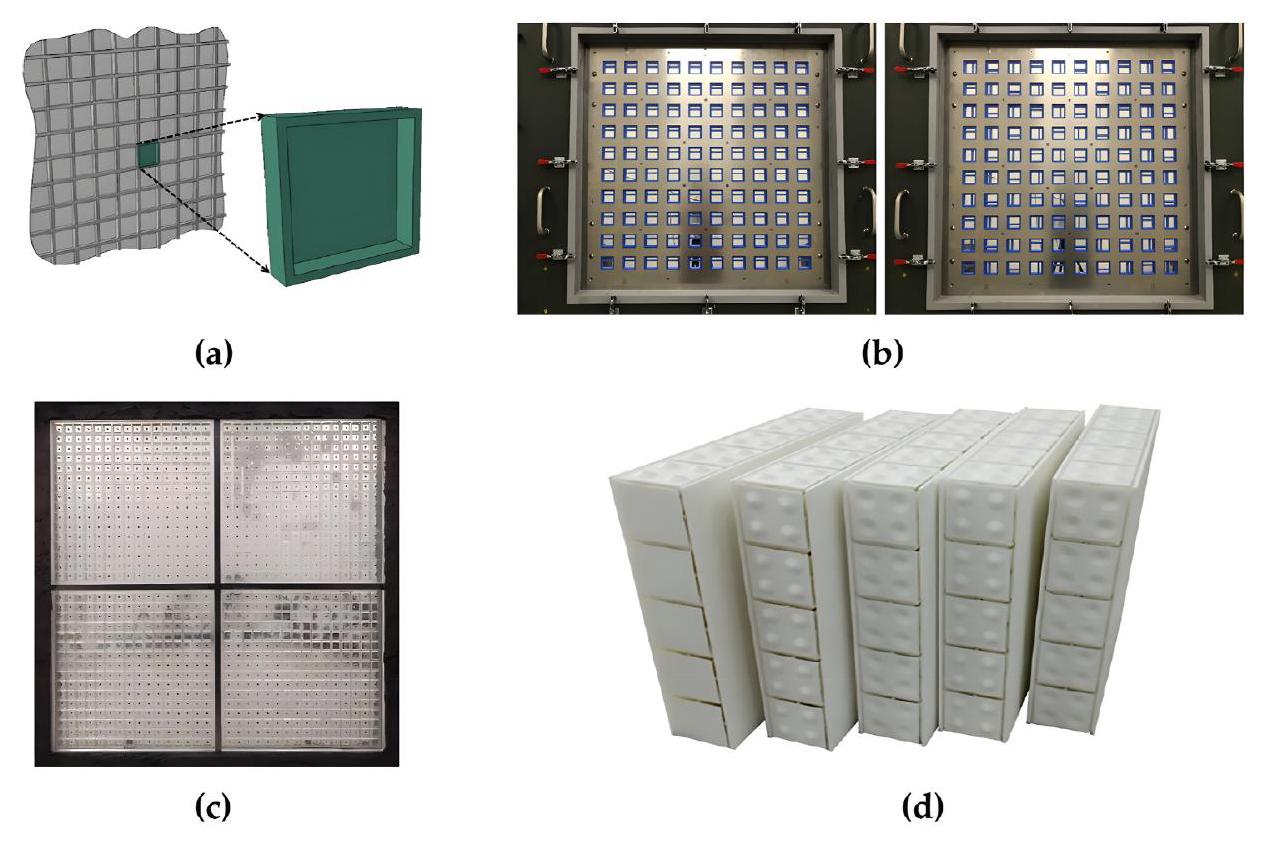

معمارية نوع الغشاء، يتأثر الأخير بالتوتر في الغشاء الذي يتغير مع الاستخدام المتكرر مما يحد من تطبيقاتها في المجالات التي تتطلب تركيبًا طويل الأمد. في هذا الصدد، قد تقدم المواد الميتا التي تتميز بمعمارية نوع اللوحة احتمالية أعلى لتقليل الضوضاء في المباني. تم تصميم معمارية ميتا صوتية خفيفة الوزن ورقيقة للغاية من نوع اللوحة تتكون من لوحة نايلون ومرن من الإيثيلين-فينيل أسيتات بواسطة ما وآخرون. كشفت البيانات أن معمارية نوع اللوحة تقدم تحسينًا في تقليل الصوت عند الترددات المنخفضة. وفقًا لفراناسي وآخرون، وُجد أن المواد الميتا من نوع اللوحة تمتلك مؤشر تقليل صوت متفوق، كما يتضح من مجموعة دورية من خلايا الوحدة التي تتكون من لوحات محتجزة ضمن إطار شبكي، كما هو موضح في الشكل 18أ. هذا التصميم نحيف وخالٍ من العناصر الرنانة الثقيلة أو المقيدة التي تحد من تطبيقه. هيكل هذه المادة الميتا من نوع اللوحة مناسب أيضًا لتطبيقات التحكم في الضوضاء حيث الهدف هو تقليل كتلة المعالجة مع تحقيق مستوى محدد.

6. المواد الميتامادية الصوتية المهواة

مع الأخذ في الاعتبار نوع جدران المباني والنوافذ والتهوية المعالجة. ومع ذلك، من أجل التنفيذ العملي على نطاق واسع للمواد الميتا الصوتية لعزل المباني، هناك حاجة إلى تطوير مستمر لهياكل خفيفة الوزن قادرة على تحمل الأحمال والتي تتمتع بقوة ودوام ملحوظين [93].

7. آفاق وتحديات المواد الميتا في عزل المباني

7.1. تخفيف الضوضاء ذات التردد المنخفض

7.2. عزل الصوت المستهدف

7.3. دمج مواد ميتا صوتية متعددة في هيكل واحد

7.4. التصنيع منخفض التكلفة والتوسع هما عقبتان رئيسيتان

المواد الميتا والتحقق من التصاميم المعقدة بفضل التقدم في تكنولوجيا الطباعة ثلاثية الأبعاد. من ناحية أخرى، بسبب نقص المتانة في عمليات التصنيع والأحجام وخصائص المواد، لا تزال تحسين العمليات والاستدامة لتكنولوجيا الطباعة ثلاثية الأبعاد تحديات كبيرة. على سبيل المثال، قد تؤثر ضغوط ما قبل الشد التي يصعب تعديلها والحفاظ عليها لفترة طويلة على بعض الميزات لمعظم المواد الميتا الصوتية من نوع الغشاء. يتم الآن إنتاج معظم المواد الميتا الصوتية من نوع الغشاء يدويًا وتتطلب مجموعة واسعة من المواد ذات الخصائص المختلفة، مما يؤدي للأسف إلى فقدان التناسق. لذلك، من الضروري تطوير تقنيات تصنيع أكثر تطورًا لاستخدام تكنولوجيا المواد الميتا الصوتية في التطبيقات الحقيقية [150].

7.5. التحكم في الصوت المنقول عبر الهيكل داخل المباني

السعة الهيكلية، والكتلة الإضافية المفروضة، ونطاق نطاقات التردد المخففة. في محاولة لفهم تطبيقات تخفيف الصوت بشكل أفضل، قام أسوار وآخرون [156] بإجراء تقييمات نظرية ورقمية لسلوك مادة ميتامادية صوتية من نوع اللوحة في بيئة صوتية جوية. تم أخذ تكوينين في الاعتبار: أحدهما يعتمد على الأعمدة والآخر على النوابض والكتلة. لقد أظهروا أن المادة الميتامادية التي تم فحصها قد تولد فقدانًا كبيرًا في نقل الصوت (STL) في نطاق التردد الصوتي، مما يشير إلى أن النظام مناسب وفعال جدًا للتطبيقات التي تتضمن تخفيف الصوت والاهتزاز. علاوة على ذلك، اقترحوا أن المادة الميتامادية من نوع اللوحة يمكن أن تكون وسيلة محتملة للتغلب على قيود تردد التوافق، مما يؤدي إلى نقل صوت عالٍ عبر الألواح لتوفير الحماية الصوتية، من خلال استخدام رنانات منخفضة التردد مختارة بعناية.

8. الاستنتاجات

بيان مساهمة مؤلفي CRediT

تحليل، تصوّر. آرون فانس: الكتابة – المراجعة والتحرير، المنهجية، التحقيق، التحليل الرسمي، التصور. أبو العرفات: الكتابة – المراجعة والتحرير، المنهجية، التحقيق، التحليل الرسمي، التصور.

إعلان عن تضارب المصالح

توفر البيانات

References

[2] A. Arjunan, A. Baroutaji, A.S. Praveen, A.G. Olabi, C.J. Wang, Acoustic performance of metallic foams, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2019, https://doi.org/10.1016/B978-0-12-803581-8.11561-9.

[3] M.H. Lu, L. Feng, Y.F. Chen, Phononic crystals and acoustic metamaterials, Mater. Today 12 (2009) 34-42, https://doi.org/10.1016/S1369-7021(09)70315-3.

[4] K.J.B. Lee, M.K. Jung, S.H. Lee, Highly tunable acoustic metamaterials based on a resonant tubular array, Phys. Rev. B Condens. Matter (2012), https://doi.org/ 10.1103/PhysRevB.86.184302.

[5] X. Zhang, Z. Qu, H. Wang, Engineering Acoustic Metamaterials for Sound Absorption: from Uniform to Gradient Structures, Elsevier Inc., 2020, https://doi. org/10.1016/j.isci.2020.101110.

[6] S.A. Cummer, J. Christensen, A. Alù, Controlling sound with acoustic metamaterials, Nat. Rev. Mater. 1 (2016), https://doi.org/10.1038/ natrevmats.2016.1.

[7] G. Ma, P. Sheng, Acoustic metamaterials: from local resonances to broad horizons, Sci. Adv. 2 (2016), https://doi.org/10.1126/sciadv. 1501595.

[8] V. Fedotov, Metamaterials, Springer Handbooks, 2017, https://doi.org/10.1007/ 978-3-319-48933-9_56.

[9] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, V.B. Nguyen, M. English, Sound frequency dependent mesh modelling to simulate the acoustic insulation of stud based double-leaf walls, in: Proc. ISMA 2014 – Int. Conf. Noise Vib. Eng. USD 2014 – Int. Conf. Uncertain, Struct. Dyn., 2014.

[10] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, V.B. Nguyen, M. English, Development of a 3D finite element acoustic model to predict the sound reduction index of stud based double-leaf walls, J. Sound Vib. 333 (2014) 6140-6155, https://doi.org/10.1016/j.jsv.2014.06.032.

[11] G. Ji, J. Huber, Recent progress in acoustic metamaterials and active piezoelectric acoustic metamaterials – a review, Appl. Mater. Today 26 (2022) 101260, https:// doi.org/10.1016/j.apmt.2021.101260.

[12] P.F. Pai, G. Huang, S. of, Photo-optical Instrumentation Engineers, Theory and Design of Acoustic Metamaterials, 2015. https://books.google.co.uk/books?id =EIdRjwEACAAJ.

[13] V. Romero-Garcia, A.C. Hladky-Hennion, Fundamentals and Applications of Acoustic Metamaterials: from Seismic to Radio Frequency, Wiley, 2019. https: //books.google.co.uk/books?id=CvulDwAAQBAJ.

[14] Z. Chen, B. Guo, Y. Yang, C. Cheng, Metamaterials-based enhanced energy harvesting: a review, Phys. B Condens. Matter (2014), https://doi.org/10.1016/j. physb.2013.12.040.

[15] N. Kaina, F. Lemoult, M. Fink, G. Lerosey, Negative refractive index and acoustic superlens from multiple scattering in single negative metamaterials, Nature (2015), https://doi.org/10.1038/nature14678.

[16] L. Terrenoir, J. Lartigau, A. Arjunan, L. Laguna Salvado, C. Merlo, Influence of wire feed speed and torch speed on the mechanical properties of wire arc additively manufactured stainless steel, J. Manuf. Sci. Eng. 145 (2023) 101012, https://doi.org/10.1115/1.4063108.

[17] A. Cano-Vicent, M.M. Tambuwala, S.S. Hassan, D. Barh, A.A.A. Aljabali, M. Birkett, A. Arjunan, Á. Serrano-Aroca, Fused deposition modelling: current status, methodology, applications and future prospects, Addit. Manuf. 47 (2021) 102378, https://doi.org/10.1016/j.addma.2021.102378.

[18] A. Arjunan, A. Baroutaji, J. Robinson, Advances in acoustic metamaterials, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2021, https://doi.org/10.1016/ B978-0-12-815732-9.00091-7.

[19] Z. Yang, J. Mei, M. Yang, N.H. Chan, P. Sheng, Membrane-type acoustic metamaterial with negative dynamic mass, Phys. Rev. Lett. (2008), https://doi. org/10.1103/PhysRevLett.101.204301.

[20] T.J. Cox, P. D’Antonio, Acoustic Absorbers and Diffusers : Theory, Design and Application, Taylor & Francis Group, Boca Raton, 2016.

[21] Y. Tao, M. Ren, H. Zhang, T. Peijs, Recent progress in acoustic materials and noise control strategies – a review, Appl. Mater. Today 24 (2021) 101141, https://doi. org/10.1016/j.apmt.2021.101141.

[22] Z. Sü, S. Yilmazer, The acoustical characteristics of the kocatepe mosque in ankara, Turkey, Architect. Sci. Rev. 51 (2008) 21-30, https://doi.org/10.3763/ asre.2008.5104.

[23] Z. Sü, M. Çalışkan, Acoustical design and noise control in metro stations: case studies of the ankara metro system, Build. Acoust. 14 (2007) 203-221, https:// doi.org/10.1260/135101007781998910.

[24] X. Peng, J. Ji, Y. Jing, Composite honeycomb metasurface panel for broadband sound absorption, J. Acoust. Soc. Am. (2018), https://doi.org/10.1121/ 1.5055847.

[25] J. Mei, G. Ma, M. Yang, Z. Yang, W. Wen, P. Sheng, Dark acoustic metamaterials as super absorbers for low-frequency sound, Nat. Commun. 3 (2012), https://doi. org/10.1038/ncomms1758.

[26] Y. Du, W. Wu, W. Chen, Y. Lin, Q. Chi, Control the structure to optimize the performance of sound absorption of acoustic metamaterial: a review, AIP Adv. 11 (2021).

[27] K. Steiger, Control of Static and Dynamic Mechanical Response of Piezoelectric Composite Shells: Applications to Acoustics and Adaptive Optics, 2013, https:// doi.org/10.13140/RG.2.1.2731.1120.

[29] C.J. Naify, C.-M. Chang, G. McKnight, F. Scheulen, S. Nutt, Membrane-type metamaterials: transmission loss of multi-celled arrays, J. Appl. Phys. 109 (2011) 104902, https://doi.org/10.1063/1.3583656.

[30] Analytic Modeling of Sound Transmission through Membrane-Type Acoustic Metamaterials – M.C. Gill Composites Center, (n.d.). https://composites.usc.edu/ 2018/04/03/soundtransmissionthroughmembrane/(accessed August 31, 2022).

[31] Y.-Z. Wang, L. Ma, Sound insulation performance of membrane-type metamaterials combined with pyramidal truss core sandwich structure, Compos. Struct. 260 (2021) 113257.

[32] F. Ma, C. Wang, C. Liu, J.H. Wu, Structural designs, principles, and applications of thin-walled membrane and plate-type acoustic/elastic metamaterials, J. Appl. Phys. 129 (2021).

[33] C.R. Fuller, G. Mathur, Poro-elastic acoustic meta materials, in: INTER-NOISE NOISE-CON Congr. Conf. Proc., Institute of Noise Control Engineering, 2017, pp. 1581-1590.

[34] X. Sagartzazu, L. Hervella-Nieto, J.M. Pagalday, Review in sound absorbing materials, Arch. Comput. Methods Eng. 15 (2008) 311-342.

[35] J. Landaluze, I. Portilla, J.M. Pagalday, A. Martínez, R. Reyero, Application of active noise control to an elevator cabin, Control Eng. Pract. 11 (2003) 1423-1431.

[36] M. Cuesta, P. Cobo, A. Fernández, J. Pfretzschner, Using a thin actuator as secondary source for hybrid passive/active absorption in an impedance tube, Appl. Acoust. 67 (2006) 15-27.

[37] W.H. Organization, Environmental Noise Guidelines for the European Region, World Health Organization. Regional Office for Europe, 2018.

[38] A. Arjunan, C. Wang, M. English, M. Stanford, P. Lister, A computationallyefficient numerical model to characterize the noise behavior of metal-framed walls, Metals 5 (2015) 1414-1431, https://doi.org/10.3390/met5031414.

[39] A. Arjunan, J. Rackley, M. Stanford, Experimental investigation on the sound reduction performance of frequency controlled acoustic interference cavities, in: Proc. INTER-NOISE 2016-45th Int. Congr. Expo. Noise Control Eng. Towar. A Quieter Futur., 2016.

[40] H.H. Huang, C.T. Sun, G.L. Huang, On the negative effective mass density in acoustic metamaterials, Int. J. Eng. Sci. (2009), https://doi.org/10.1016/j. ijengsci.2008.12.007.

[41] M.R. Haberman, M.D. Guild, Acoustic metamaterials, Phys. Today (2016), https://doi.org/10.1063/PT.3.3198.

[42] M. Caleap, B.W. Drinkwater, P.D. Wilcox, Effective dynamic constitutive parameters of acoustic metamaterials with random microstructure, New J. Phys. 14 (2012) 33014, https://doi.org/10.1088/1367-2630/14/3/033014.

[43] P. Sheng, J. Mei, Z. Liu, W. Wen, Dynamic mass density and acoustic metamaterials, Phys. B Condens. Matter (2007), https://doi.org/10.1016/j. physb.2006.12.046.

[44] M.I. Hussein, M.J. Frazier, Damped Phononic Crystals and Acoustic Metamaterials, 2013, https://doi.org/10.1007/978-3-642-31232-8_6.

[45] M.F. Ponge, O. Poncelet, D. Torrent, Dynamic homogenization theory for nonlocal acoustic metamaterials, Extrem. Mech. Lett. (2017), https://doi.org/ 10.1016/j.eml.2016.10.006.

[46] C. Coulais, D. Sounas, A. Alù, Static non-reciprocity in mechanical metamaterials, Nature (2017), https://doi.org/10.1038/nature21044.

[47] M. Kadic, T. Bückmann, R. Schittny, M. Wegener, Metamaterials beyond electromagnetism, Rep. Prog. Phys. (2013), https://doi.org/10.1088/0034-4885/ 76/12/126501.

[48] J. Liu, H. Guo, T. Wang, A review of acoustic metamaterials and phononic crystals, Crystals (2020), https://doi.org/10.3390/cryst10040305.

[49] X. Zhou, X. Liu, G. Hu, Elastic metamaterials with local resonances: an overview, Theor. Appl. Mech. Lett. (2012), https://doi.org/10.1063/2.1204101.

[50] V. Fokin, M. Ambati, C. Sun, X. Zhang, Method for retrieving effective properties of locally resonant acoustic metamaterials, Phys. Rev. B Condens. Matter (2007), https://doi.org/10.1103/PhysRevB.76.144302.

[51] S. Kumar, H. Lee, The present and future role of acoustic metamaterials for architectural and urban noise mitigations, Acoustics (2019), https://doi.org/ 10.3390/acoustics1030035.

[52] M.D. Guild, V.M. García-Chocano, W. Kan, J. Sánchez-Dehesa, Acoustic metamaterial absorbers based on multilayered sonic crystals, J. Appl. Phys. (2015), https://doi.org/10.1063/1.4915346.

[53] Y. Tang, S. Ren, H. Meng, F. Xin, L. Huang, T. Chen, C. Zhang, T.J. Lu, Hybrid acoustic metamaterial as super absorber for broadband low-frequency sound, Sci. Rep. (2017), https://doi.org/10.1038/srep43340.

[54] T. Lee, T. Nomura, E.M. Dede, H. Iizuka, Ultrasparse acoustic absorbers enabling fluid flow and visible-light controls, Phys. Rev. Appl. (2019), https://doi.org/ 10.1103/PhysRevApplied.11.024022.

[55] A.C. Slagle, C.R. Fuller, Low frequency noise reduction using poro-elastic acoustic metamaterials, in: 21st AIAA/CEAS Aeroacoustics Conf, 2015, https://doi.org/ 10.2514/6.2015-3113.

[56] X. Jiang, B. Liang, R.Q. Li, X.Y. Zou, L.L. Yin, J.C. Cheng, Ultra-broadband absorption by acoustic metamaterials, Appl. Phys. Lett. (2014), https://doi.org/ 10.1063/1.4904887.

[57] S. Ebrahimi-Nejad, M. Kheybari, Honeycomb locally resonant absorbing acoustic metamaterials with stop band behavior, Mater. Res. Express (2018), https://doi. org/10.1088/2053-1591/aadbe2.

[58] S. Cho, B. Kim, D. Min, J. Kang, J. Park, Acoustic metamaterial panel composed of funnel-shaped cell unit having multi-band negative material properties, in: INTERNOISE 2014-43rd Int. Congr. Noise Control Eng. Improv, World Through Noise Control, 2014.

[59] J. Niu, J. Wu, Low frequency wide band sound absorption performance of asymmetric type acoustic metamaterials, Zhendong Yu Chongji/Journal Vib. Shock. (2018), https://doi.org/10.13465/j.cnki.jvs.2018.19.007.

[60] S. Ortiz, C. Gonzalez, P. Cobo, F. Montero de Espinosa, Attenuating open cavity tones by lining its walls with microperforated panels, Noise Control Eng. J. 62 (2014) 145-151, https://doi.org/10.3397/1/376215.

[61] J. Pfretzschner, P. Cobo, F. Simón, M. Cuesta, A. Fernández, Microperforated insertion units: an alternative strategy to design microperforated panels, Appl. Acoust. 67 (2006) 62-73, https://doi.org/10.1016/j.apacoust.2005.05.005.

[62] S. Greiner, K. Wudy, L. Lanzl, D. Drummer, Selective laser sintering of polymer blends: bulk properties and process behavior, Polym. Test. 64 (2017) 136-144, https://doi.org/10.1016/j.polymertesting.2017.09.039.

[63] A. Arjunan, M. Demetriou, A. Baroutaji, C. Wang, Mechanical performance of highly permeable laser melted Ti6Al4V bone scaffolds, J. Mech. Behav. Biomed. Mater. 102 (2020) 103517, https://doi.org/10.1016/j.jmbbm.2019.103517.

[64] A. Arjunan, Acoustic absorption of passive destructive interference cavities, Mater. Today Commun. 19 (2019) 68-75, https://doi.org/10.1016/j. mtcomm.2018.12.012.

[65] A. Arjunan, Targeted sound attenuation capacity of 3D printed noise cancelling waveguides, Appl. Acoust. 151 (2019) 30-44, https://doi.org/10.1016/j. apacoust.2019.03.008.

[67] H. Xie, Y. Lyu, Sound absorption characteristics of the perforated panel resonator with tube bundles, 21st Int. Congr. Sound Vib. (2014), Volume 1, pp. 5010, ICSV 2014, 2014.

[68] X. Wang, Y. Chen, G. Zhou, T. Chen, F. Ma, Synergetic coupling large-scale platetype acoustic metamaterial panel for broadband sound insulation, J. Sound Vib. (2019), https://doi.org/10.1016/j.jsv.2019.114867.

[69] S.W. Ren, L. Van Belle, C. Claeys, F.X. Xin, T.J. Lu, E. Deckers, W. Desmet, Improvement of the sound absorption of flexible micro-perforated panels by local resonances, Mech. Syst. Signal Process. (2019), https://doi.org/10.1016/j. ymssp.2018.07.046.

[70] T.A. Starkey, J.D. Smith, A.P. Hibbins, J.R. Sambles, H.J. Rance, Thin structured rigid body for acoustic absorption, Appl. Phys. Lett. (2017), https://doi.org/ 10.1063/1.4974487.

[71] L.J. Li, B. Zheng, L.M. Zhong, J. Yang, B. Liang, J.C. Cheng, Broadband compact acoustic absorber with high-efficiency ventilation performance, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5038184.

[72] S. Huang, X. Fang, X. Wang, B. Assouar, Q. Cheng, Y. Li, Acoustic perfect absorbers via Helmholtz resonators with embedded apertures, J. Acoust. Soc. Am. (2019), https://doi.org/10.1121/1.5087128.

[73] C.R. Liu, J.H. Wu, X. Chen, F. Ma, A thin low-frequency broadband metasurface with multi-order sound absorption, J. Phys. D Appl. Phys. (2019), https://doi. org/10.1088/1361-6463/aafaa3.

[74] A.A. Fernández-Marín, N. Jiménez, J.P. Groby, J. Sánchez-Dehesa, V. RomeroGarcía, Aerogel-based metasurfaces for perfect acoustic energy absorption, Appl. Phys. Lett. (2019), https://doi.org/10.1063/1.5109084.

[75] X. Cai, Q. Guo, G. Hu, J. Yang, Ultrathin low-frequency sound absorbing panels based on coplanar spiral tubes or coplanar Helmholtz resonators, Appl. Phys. Lett. 105 (2014) 121901, https://doi.org/10.1063/1.4895617.

[76] S. Huang, X. Fang, X. Wang, B. Assouar, Q. Cheng, Y. Li, Acoustic perfect absorbers via spiral metasurfaces with embedded apertures, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5063289.

[77] G. Ma, M. Yang, S. Xiao, Z. Yang, P. Sheng, Acoustic metasurface with hybrid resonances, Nat. Mater. 13 (2014) 873-878, https://doi.org/10.1038/nmat3994.

[78] Y. Aurégan, Ultra-thin low frequency perfect sound absorber with high ratio of active area, Appl. Phys. Lett. 113 (2018) 201904, https://doi.org/10.1063/ 1.5063504.

[79] X. Wang, X. Luo, H. Zhao, Z. Huang, Acoustic perfect absorption and broadband insulation achieved by double-zero metamaterials, Appl. Phys. Lett. 112 (2018) 21901, https://doi.org/10.1063/1.5018180.

[80] C. Xu, H. Guo, Y. Chen, X. Dong, H. Ye, Y. Wang, Study on broadband lowfrequency sound insulation of multi-channel resonator acoustic metamaterials, AIP Adv. 11 (2021) 45321, https://doi.org/10.1063/5.0047416.

[81] F. Zangeneh-Nejad, R. Fleury, Active times for acoustic metamaterials, Rev. Phys. 4 (2019) 100031, https://doi.org/10.1016/j.revip.2019.100031.

[82] A. Arjunan, A. Baroutaji, J. Robinson, C. Wang, Characteristics of acoustic metamaterials, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2021, https:// doi.org/10.1016/B978-0-12-815732-9.00090-5.

[83] A. Arjunan, A. Baroutaji, A. Latif, Acoustic behaviour of 3D printed titanium perforated panels, Results Eng 11 (2021) 100252, https://doi.org/10.1016/j. rineng.2021.100252.

[84] Y. Li, B.M. Assouar, Acoustic metasurface-based perfect absorber with deep subwavelength thickness, Appl. Phys. Lett. 108 (2016) 63502, https://doi.org/ 10.1063/1.4941338.

[85] X.H. Zhang, Z.G. Qu, X.C. He, D.L. Lu, Experimental study on the sound absorption characteristics of continuously graded phononic crystals, AIP Adv. 6 (2016) 105205, https://doi.org/10.1063/1.4965923.

[86] A. Climente, D. Torrent, J. Sánchez-Dehesa, Omnidirectional broadband acoustic absorber based on metamaterials, Appl. Phys. Lett. 100 (2012), https://doi.org/ 10.1063/1.3701611.

[87] J. Xu, S. Xiao, P. He, Y. Wang, Y. Shen, L. Hong, Y. Luo, B. He, Realization of broadband truly rainbow trapping in gradient-index metamaterials, Opt Express 30 (2022) 3941-3953.

[88] Z.-Y. Li, T.-X. Ma, Y.-Z. Wang, F.-M. Li, C. Zhang, Vibration isolation by novel meta-design of pyramid-core lattice sandwich structures, J. Sound Vib. 480 (2020) 115377.

[89] Y. Xu, Y. Fu, H. Chen, Planar gradient metamaterials, Nat. Rev. Mater. 1 (2016), https://doi.org/10.1038/natrevmats.2016.67.

[90] J. Zhu, Y. Chen, X. Zhu, F.J. Garcia-Vidal, X. Yin, W. Zhang, X. Zhang, Acoustic rainbow trapping, Sci. Rep. 3 (2013) 1728, https://doi.org/10.1038/srep01728.

[91] M. Alshaqaq, C. Sugino, A. Erturk, Programmable rainbow trapping and band-gap enhancement via spatial group-velocity tailoring in elastic metamaterials, Phys. Rev. Appl. 17 (2022) L021003, https://doi.org/10.1103/PhysRevApplied.17. L021003.

[92] X. Ni, Y. Wu, Z.-G. Chen, L.-Y. Zheng, Y.-L. Xu, P. Nayar, X.-P. Liu, M.-H. Lu, Y.F. Chen, Acoustic rainbow trapping by coiling up space, Sci. Rep. 4 (2014) 7038, https://doi.org/10.1038/srep07038.

[93] N. Gao, Z. Zhang, J. Deng, X. Guo, B. Cheng, H. Hou, Acoustic Metamaterials for Noise Reduction: A Review, Adv. Mater. Technol. n/a (n.d.) 2100698. https://d oi.org/10.1002/admt. 202100698.

[94] W. Akl, A. Baz, Experimental characterization of active acoustic metamaterial cell with controllable dynamic density, J. Appl. Phys. 112 (2012) 84912, https://doi. org/10.1063/1.4759327.

[95] J. Zhao, X. Li, Y. Wang, W. Wang, B. Zhang, X. Gai, Membrane acoustic metamaterial absorbers with magnetic negative stiffness, J. Acoust. Soc. Am. 141 (2017) 840-846, https://doi.org/10.1121/1.4976042.

[96] X. Li, T. Xing, J. Zhao, X. Gai, Broadband low frequency sound absorption using a monostable acoustic metamaterial, J. Acoust. Soc. Am. 147 (2020), https://doi. org/10.1121/10.0000714. EL113-EL118.

[97] X. Xiang, H. Tian, Y. Huang, X. Wu, W. Wen, Manually tunable ventilated metamaterial absorbers, Appl. Phys. Lett. 118 (2021) 53504, https://doi.org/ 10.1063/5.0037547.

[98] Z. Xu, H. Meng, A. Chen, J. Yang, B. Liang, J. Cheng, Tunable low-frequency and broadband acoustic metamaterial absorber, J. Appl. Phys. 129 (2021) 94502, https://doi.org/10.1063/5.0038940.

[99] J. Du, Y. Luo, X. Zhao, X. Sun, Y. Song, X. Hu, Bilayer ventilated labyrinthine metasurfaces with high sound absorption and tunable bandwidth, Sci. Rep. 11 (2021) 5829, https://doi.org/10.1038/s41598-021-84986-0.

[100] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, M. English, Finite element acoustic analysis of a steel stud based double-leaf wall, Build. Environ. 67 (2013) 202-210, https://doi.org/10.1016/j.buildenv.2013.05.021.

[101] J. Li, X. Zhou, G. Huang, G. Hu, Acoustic metamaterials capable of both sound insulation and energy harvesting, Smart Mater. Struct. (2016), https://doi.org/ 10.1088/0964-1726/25/4/045013.

[102] C.J. Naify, C.M. Chang, G. McKnight, S. Nutt, Transmission loss and dynamic response of membrane-type locally resonant acoustic metamaterials, J. Appl. Phys. (2010), https://doi.org/10.1063/1.3514082.

[103] M. Yang, G. Ma, Z. Yang, P. Sheng, Coupled membranes with doubly negative mass density and bulk modulus, Phys. Rev. Lett. (2013), https://doi.org/ 10.1103/PhysRevLett.110.134301.

[104] S. Kumar, P. Bhushan, O. Prakash, S. Bhattacharya, Double negative acoustic metastructure for attenuation of acoustic emissions, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5022602.

[105] F. Ma, M. Huang, J.H. Wu, Ultrathin lightweight plate-type acoustic metamaterials with positive lumped coupling resonant, J. Appl. Phys. (2017), https://doi.org/10.1063/1.4972839.

[106] F. Ma, M. Huang, Y. Xu, J.H. Wu, Bi-layer plate-Type acoustic metamaterials with Willis coupling, J. Appl. Phys. (2018), https://doi.org/10.1063/1.4991426.

[107] L.Y.L. Ang, Y.K. Koh, H.P. Lee, Plate-type acoustic metamaterial with cavities coupled via an orifice for enhanced sound transmission loss, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5019602.

[108] A. Arjunan, A. Foteinou, A comparative study on the acoustic behaviour of freestanding curved and flat single panel screens in an open-plan enclosed environment, in: INTER-NOISE 2017-46th Int. Congr. Expo. Noise Control Eng, Taming Noise Mov. Quiet, 2017.

[109] Z. Li, D.Q. Yang, S.L. Liu, S.Y. Yu, M.H. Lu, J. Zhu, S.T. Zhang, M.W. Zhu, X. S. Guo, H.D. Wu, X.L. Wang, Y.F. Chen, Broadband gradient impedance matching using an acoustic metamaterial for ultrasonic transducers, Sci. Rep. (2017), https://doi.org/10.1038/srep42863.

[110] F. Casadei, T. Delpero, A. Bergamini, P. Ermanni, M. Ruzzene, Piezoelectric resonator arrays for tunable acoustic waveguides and metamaterials, J. Appl. Phys. (2012), https://doi.org/10.1063/1.4752468.

[111] S.B. Chen, J.H. Wen, G. Wang, X. Sen Wen, Tunable band gaps in acoustic metamaterials with periodic arrays of resonant shunted piezos, Chin. Phys. B (2013), https://doi.org/10.1088/1674-1056/22/7/074301.

[112] A. Allam, A. Elsabbagh, W. Akl, Modeling and design of two-dimensional membrane-type active acoustic metamaterials with tunable anisotropic density, J. Acoust. Soc. Am. (2016), https://doi.org/10.1121/1.4966627.

[113] W. Akl, A. Baz, Multi-cell active acoustic metamaterial with programmable bulk modulus, J. Intell. Mater. Syst. Struct. (2010), https://doi.org/10.1177/ 1045389X09359434.

[114] L. Airoldi, M. Ruzzene, Design of tunable acoustic metamaterials through periodic arrays of resonant shunted piezos, New J. Phys. (2011), https://doi.org/10.1088/ 1367-2630/13/11/113010.

[115] C. Sugino, S. Leadenham, M. Ruzzene, A. Erturk, An investigation of electroelastic bandgap formation in locally resonant piezoelectric metastructures, Smart Mater. Struct. (2017), https://doi.org/10.1088/1361-665X/aa6671.

[116] F. Casadei, M. Ruzzene, L. Dozio, K.A. Cunefare, Broadband vibration control through periodic arrays of resonant shunts: experimental investigation on plates, Smart Mater. Struct. (2010), https://doi.org/10.1088/0964-1726/19/1/015002.

[117] S. Chen, Y. Fan, Q. Fu, H. Wu, Y. Jin, J. Zheng, F. Zhang, A review of tunable acoustic metamaterials, Appl. Sci. (2018), https://doi.org/10.3390/app8091480.

[118] A. Allam, A. Elsabbagh, W. Akl, Experimental demonstration of one-dimensional active plate-type acoustic metamaterial with adaptive programmable density, J. Appl. Phys. (2017), https://doi.org/10.1063/1.4979020.

[119] B.I. Popa, L. Zigoneanu, S.A. Cummer, Tunable active acoustic metamaterials, Phys. Rev. B Condens. Matter (2013), https://doi.org/10.1103/ PhysRevB.88.024303.

[120] P. Wang, F. Casadei, S. Shan, J.C. Weaver, K. Bertoldi, Harnessing buckling to design tunable locally resonant acoustic metamaterials, Phys. Rev. Lett. (2014), https://doi.org/10.1103/PhysRevLett.113.014301.

[121] Z. Yang, H.M. Dai, N.H. Chan, G.C. Ma, P. Sheng, Acoustic metamaterial panels for sound attenuation in the

[122] Y. Zhang, J. Wen, Y. Xiao, X. Wen, J. Wang, Theoretical investigation of the sound attenuation of membrane-type acoustic metamaterials, Phys. Lett. 376 (2012) 1489-1494, https://doi.org/10.1016/j.physleta.2012.03.010.

[123] Y. Chen, G. Huang, X. Zhou, G. Hu, C.-T. Sun, Analytical coupled vibroacoustic modeling of membrane-type acoustic metamaterials: membrane model, J. Acoust. Soc. Am. 136 (2014) 969-979, https://doi.org/10.1121/1.4892870.

[124] C.J. Naify, C.-M. Chang, G. McKnight, S. Nutt, Transmission loss of membranetype acoustic metamaterials with coaxial ring masses, J. Appl. Phys. 110 (2011) 124903, https://doi.org/10.1063/1.3665213.

[125] H. Tian, X. Wang, Y. Zhou, Theoretical model and analytical approach for a circular membrane-ring structure of locally resonant acoustic metamaterial, Appl. Phys. A 114 (2014) 985-990, https://doi.org/10.1007/s00339-013-8047-y.

[126] C.J. Naify, C.-M. Chang, G. McKnight, S.R. Nutt, Scaling of membrane-type locally resonant acoustic metamaterial arrays, J. Acoust. Soc. Am. 132 (2012) 2784-2792, https://doi.org/10.1121/1.4744941.

[127] N. Sui, X. Yan, T.-Y. Huang, J. Xu, F.-G. Yuan, Y. Jing, A lightweight yet soundproof honeycomb acoustic metamaterial, Appl. Phys. Lett. 106 (2015) 171905, https://doi.org/10.1063/1.4919235.

[128] X. Wang, H. Zhao, X. Luo, Z. Huang, Membrane-constrained acoustic metamaterials for low frequency sound insulation, Appl. Phys. Lett. 108 (2016) 41905, https://doi.org/10.1063/1.4940717.

[129] J. Jin Park, J.-H. Kwak, K. Song, Ultraslow medium with an acoustic membranelike undamped dynamic vibration absorber for low-frequency isolation, Extrem. Mech. Lett. 43 (2021) 101203, https://doi.org/10.1016/j.eml.2021.101203.

[130] F. Langfeldt, W. Gleine, Design of acoustic partitions with thin plate-like acoustic metamaterials, in: Proc. Int. Congr. Acoust., 23rd International Congress on Acoustics, 2019, pp. 4870-4877, https://doi.org/10.18154/RWTH-CONV239261. Achen, Germany.

[131] S. Varanasi, J.S. Bolton, T.H. Siegmund, R.J. Cipra, The low frequency performance of metamaterial barriers based on cellular structures, Appl. Acoust. 74 (2013) 485-495, https://doi.org/10.1016/j.apacoust.2012.09.008.

[132] L.Y.L. Ang, Y.K. Koh, H.P. Lee, Plate-type acoustic metamaterials: evaluation of a large-scale design adopting modularity for customizable acoustical performance, Appl. Acoust. 149 (2019) 156-170, https://doi.org/10.1016/j. apacoust.2019.01.027.

[133] Q. Lin, Q. Lin, Y. Wang, G. Di, Sound insulation performance of sandwich structure compounded with a resonant acoustic metamaterial, Compos. Struct. 273 (2021) 114312, https://doi.org/10.1016/j.compstruct.2021.114312.

[134] C. Gazzola, S. Caverni, A. Corigliano, From mechanics to acoustics: critical assessment of a robust metamaterial for acoustic insulation application, Appl. Acoust. 183 (2021) 108311, https://doi.org/10.1016/j.apacoust.2021.108311.

[135] M.H.F.H.F. De Salis, D.J.J. Oldham, S. Sharples, Noise control strategies for naturally ventilated buildings, Build. Environ. 37 (2002) 471-484, https://doi. org/10.1016/S0360-1323(01)00047-6.

[136] S.-H. Kim, S.-H. Lee, Air transparent soundproof window, AIP Adv. 4 (2014) 117123, https://doi.org/10.1063/1.4902155.

[137] X. Yu, Z. Lu, L. Cheng, F. Cui, On the sound insulation of acoustic metasurface using a sub-structuring approach, J. Sound Vib. 401 (2017) 190-203, https://doi. org/10.1016/j.jsv.2017.04.042.

[138] S. Kumar, T.B. Xiang, H.P. Lee, Ventilated acoustic metamaterial window panels for simultaneous noise shielding and air circulation, Appl. Acoust. 159 (2020) 107088, https://doi.org/10.1016/j.apacoust.2019.107088.

[139] Z. Xiao, P. Gao, D. Wang, X. He, L. Wu, Ventilated metamaterials for broadband sound insulation and tunable transmission at low frequency, Extrem. Mech. Lett. 46 (2021) 101348, https://doi.org/10.1016/j.eml.2021.101348.

[140] J.W. Jung, J.E. Kim, J.W. Lee, Acoustic metamaterial panel for both fluid passage and broadband soundproofing in the audible frequency range, Appl. Phys. Lett. 112 (2018) 41903, https://doi.org/10.1063/1.5004605.

[141] R. Ghaffarivardavagh, J. Nikolajczyk, S. Anderson, X. Zhang, Ultra-open acoustic metamaterial silencer based on Fano-like interference, Phys. Rev. B 99 (2019) 24302, https://doi.org/10.1103/PhysRevB.99.024302.

[142] X. Wu, K.Y. Au-Yeung, X. Li, R.C. Roberts, J. Tian, C. Hu, Y. Huang, S. Wang, Z. Yang, W. Wen, High-efficiency ventilated metamaterial absorber at low frequency, Appl. Phys. Lett. 112 (2018).

[143] H. Zhang, Y. Zhu, B. Liang, J. Yang, J. Yang, J. Cheng, Omnidirectional ventilated acoustic barrier, Appl. Phys. Lett. 111 (2017).

[144] A. Crivoi, L. Du, Z. Fan, Ventilated acoustic meta-barrier based on layered Helmholtz resonators, Appl. Acoust. 205 (2023) 109263.

[145] Z. Su, Y. Zhu, S. Gao, H. Luo, H. Zhang, High-efficient and broadband acoustic insulation in a ventilated channel with acoustic metamaterials, Front. Mech. Eng. 8 (2022) 857788.

[146] X. Xiang, X. Wu, X. Li, P. Wu, H. He, Q. Mu, S. Wang, Y. Huang, W. Wen, Ultraopen ventilated metamaterial absorbers for sound-silencing applications in environment with free air flows, Extrem. Mech. Lett. 39 (2020) 100786.

[147] M. Sun, X. Fang, D. Mao, X. Wang, Y. Li, Broadband acoustic ventilation barriers, Phys. Rev. Appl. 13 (2020) 44028.

[148] A. Trematerra, A. Bevilacqua, G. Iannace, Noise control in air mechanical ventilation systems with three-dimensional metamaterials, Appl. Sci. 13 (2023) 1650.

[149] N. Jiménez, V. Romero-García, V. Pagneux, J.-P. Groby, Quasiperfect absorption by subwavelength acoustic panels in transmission using accumulation of resonances due to slow sound, Phys. Rev. B 95 (2017) 14205, https://doi.org/ 10.1103/PhysRevB.95.014205.

[150] G. Liao, C. Luan, Z. Wang, J. Liu, X. Yao, J. Fu, Acoustic metamaterials: a review of theories, structures, fabrication approaches, and applications, Adv. Mater. Technol. 6 (2021) 2000787, https://doi.org/10.1002/admt.202000787.

[151] Y. Wu, M. Yang, P. Sheng, Perspective: acoustic metamaterials in transition, J. Appl. Phys. (2018), https://doi.org/10.1063/1.5007682.

[152] D.J. Jagodzinski, M. Miksch, Q. Aumann, G. Müller, Modeling and optimizing an acoustic metamaterial to minimize low-frequency structure-borne sound, Mech. Base. Des. Struct. Mach. 50 (2022) 2877-2891.

[153] C.M. Harris, Absorption of sound in air versus humidity and temperature, J. Acoust. Soc. Am. 40 (1966) 148-159. https://api.semanticscholar.org/Corpus ID:120738552.

[154] D.A. Bohn, Environmental effects on the speed of sound, J. Audio Eng. Soc. 36 (1988) 223-231. https://api.semanticscholar.org/CorpusID:18639998.

[155] B. Gibson, T. Nguyen, S. Sinaie, D. Heath, T. Ngo, The low frequency structureborne sound problem in multi-storey timber buildings and potential of acoustic metamaterials: a review, Build. Environ. (2022) 109531.

[156] B. Assouar, M. Oudich, X. Zhou, Acoustic metamaterials for sound mitigation, Compt. Rendus Phys. 17 (2016) 524-532, https://doi.org/10.1016/j. crhy.2016.02.002.

- Corresponding author. School of Engineering, Faculty of Science and Engineering, University of Wolverhampton, Telford Campus, Shifnal Road, Priorslee, Telford, TF2 9NT, United Kingdom.

E-mail address: a.arjunan@wlv.ac.uk (A. Arjunan).

DOI: https://doi.org/10.1016/j.buildenv.2024.111250

Publication Date: 2024-01-29

Acoustic metamaterials for sound absorption and insulation in buildings

A R T I C L E I N F O

Keywords:

Sound insulation

Sound reduction

Ventilation

Building design

Abstract

Despite the emergence of acoustic metamaterials with superior sound absorption and transmission loss, their adoption for building sound insulation has been limited. Sound insulation design in buildings is still informed by the acoustic performance of conventional materials, where the mass law contradicts light weighting when it comes to acoustic design. In any case buildings close to noisy environments such as motorways, railway lines and airports still suffer from significant low frequency noise pollution. Although the limited working bandwidth of acoustic metamaterials is a major issue limiting its application, combining meta-units that interact at various frequencies alongside multi-layer conventional solutions can deliver superior sound insulation in buildings. The review put forwards acoustic metamaterials, specifically emphasising superior sound absorption and transmission/insertion loss as critical properties for effective building sound insulation. The paper reveals a variety of acoustic metamaterials that can be adopted to compliment conventional sound insulation approaches for acoustically efficient building design. The performance of these metamaterials is then explained through their characteristic negative mass density, bulk modulus or repeating or locally resonating microstructure. The review is also extended to air transparent acoustic metamaterials that can be used for sound insulation of building ventilation. Lastly the prospects and challenges regarding the adoption of acoustic metamaterials in building insulation are also discussed. Overall, tuneable, and multifunctional acoustic metamaterials when thoughtfully integrated to building sound insulation can lead to significant acoustic comfort, space-saving and lightweighting.

1. Introduction

stiffness architecture allowing them to be conceived into a variety of suitable bulk materials [2].

2. Basic aspects of acoustic metamaterials in building design

2.1. Relevance of acoustic metamaterials

2.2. Sound absorption

determined by the acoustic characteristics of the structure, and surfaces that effectively absorb sound are referred to as good sound absorbers. A visual representation of a building environment with and without sound absorption treatments is depicted in Fig. 2, illustrating the temporal and spatial aspects of sound within a space.

Treatment Temporal response Spatial response

2.3. Soundproofing or sound reduction

walled membrane- and plate-type structures are anticipated to become the standard option for low-frequency vibration and noise reduction in practical engineering due to their benefits, which include decreased thickness and low surface density. In thin plate-type AMMs, the holes or pillars are often placed on a continuous plate with changeable thickness and holes or pillars of different sizes and shapes [32]. In contrast to the plate-type AMM, the membrane-type AMM always uses a frame to divide individual cells while one or more masses are organised on the membrane. Initial stress must be given to the membrane to sustain the propagation of vibrations, as the membrane’s stiffness is insufficient to resist its own gravity.

2.4. Passive and active controlled sound absorption and sound reduction

3. Acoustic metamaterial features for building applications

3.1. Concepts of negative mass density and bulk modulus

that characterises the compressibility of a substance. Mathematically, the bulk modulus is defined as the ratio of the change in pressure to the fractional change in volume. Materials with a high bulk modulus are less compressible, meaning they resist changes in volume more effectively. Liquids and solids typically have non-negative bulk moduli, while gases can have negative bulk moduli under certain conditions. It is a key parameter in acoustic metamaterials because it can be used to control the speed and direction of sound waves. By adjusting the bulk modulus of a material, it is possible to manipulate the propagation of sound waves. Together,

3.2. Dynamic microstructure

acoustic metamaterials with tailored properties. The figure highlights the potential for achieving negative mass and stiffness, paving the way for innovative applications in sound control and wave manipulation within the field of acoustic metamaterials.

4. Acoustic metamaterials for sound absorption

4.1. Helmholtz type architecture

mass concentrators within a porous architecture, leading to exceptional

4.2. Membrane type architecture

Acoustic metamaterials that offer high frequency dependent sound absorption suitable for application in building acoustics [5].

| Material | Size (mm) | Frequency (Hz) | Ref. |

| Honeycomb corrugated core combined with resonance cavities | 60 | 2000 | [53] |

| Waveguide that combines tubes and MPP metamaterials | 54 | 800-1000 | [71] |

| Acoustic metamaterial combining Helmholtz apertures | 50 | 130-170 | [72] |

| Helmholtz resonators featuring microperforated panels | 62 | 450-1360 | [73] |

| Resonance cavities featuring aerogels | 42 | 600 | [74] |

| Metamaterials featuring coplanar waveguides | 17 | 600 | [75] |

| Coiled waveguides that feature geometrical features | 24 | 146-168 | [76] |

4.3. Space coiling acoustic metamaterials

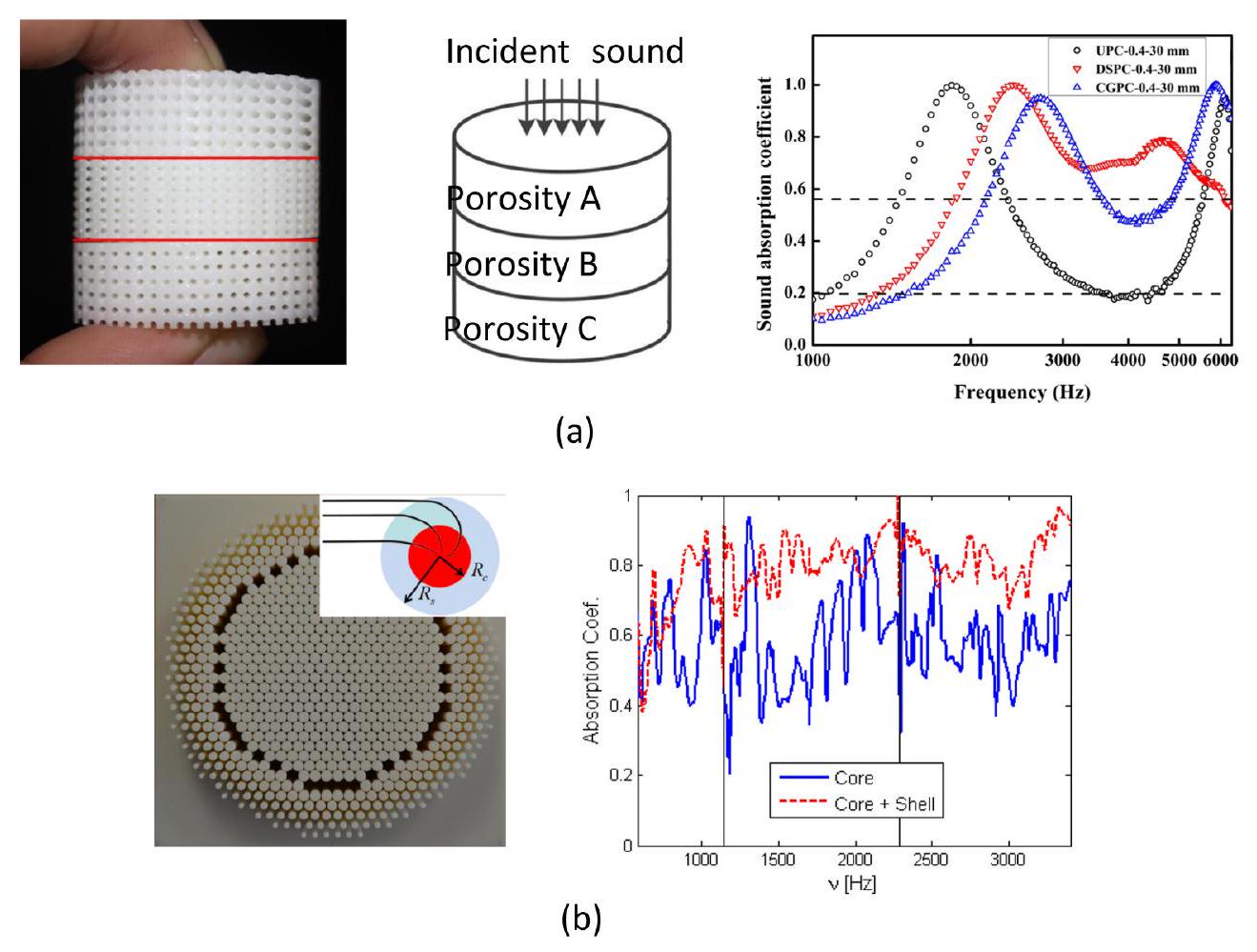

perfect absorption, their large-scale fabrication to be used in building acoustics is challenging. However, this can be overcome by using space coiling acoustic metamaterials which can also achieve near perfect sound absorption. As such the primary advantage of space coiling acoustic metamaterial over membrane based is their ease of scalability

Fig. 11 shows examples of space coiling metamaterials that are suitable from a building acoustics point of view. For these metamaterials, the length, size, and volume of space coiling can be manipulated to achieve near perfect absorption at a range of audible frequencies. For instance, the space coiling architecture in Fig. 11a developed by Cai et al. [75] is capable almost

solid material.

4.4. Gradient index acoustic metamaterials

4.5. Tunable acoustic metamaterials

5. Acoustic metamaterials for sound insulation

5.1. Poroelastic metamaterials

proven to be effective in sound barrier applications. Another methodology involves planar meta-structures with linked cavities through an orifice, which was selected to improve the sound reduction index. The findings indicate that the coupling effect between enclosed cavities linked through an orifice can influence sound behaviour. Thus, the orifice’s radius can be adjusted to achieve frequency-dependent performance. This design has significant potential as a noise barrier [38,108] and can address concerns related to membrane metamaterials. These examples demonstrate how acoustic metamaterials can be used to create scalable sound barriers that are suitable for mass production.

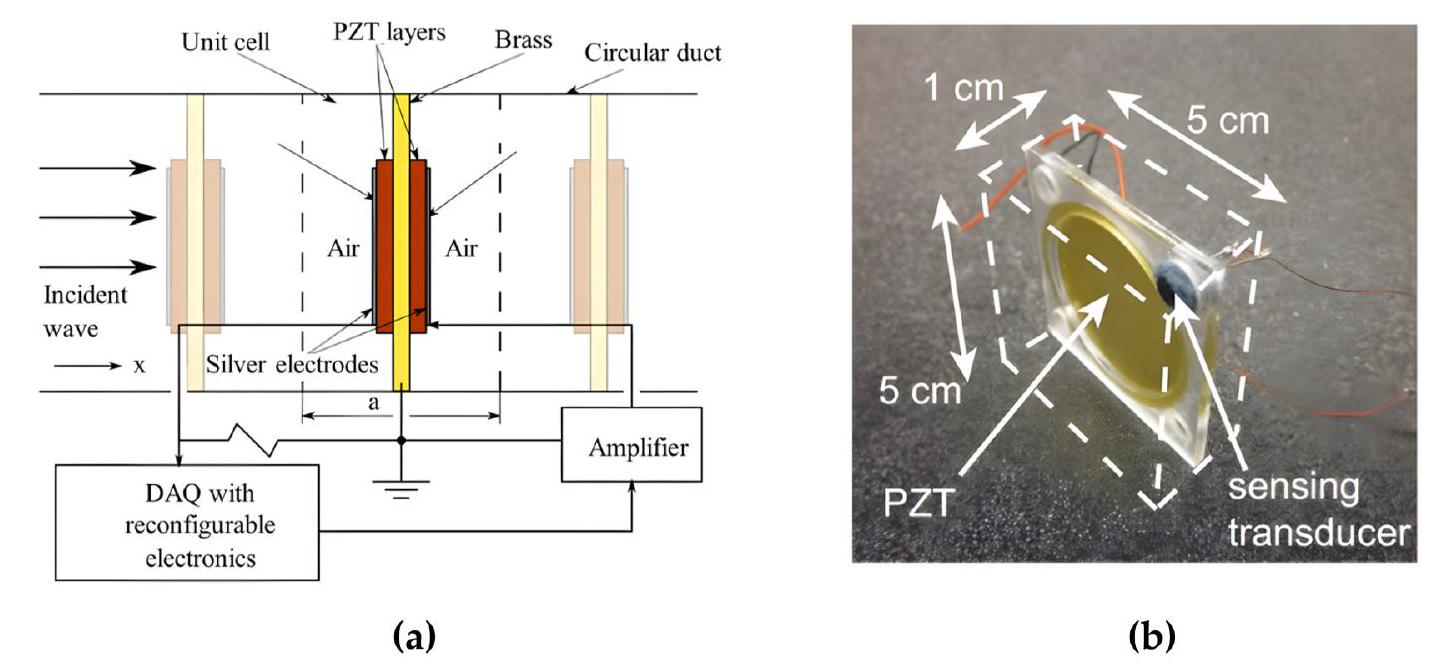

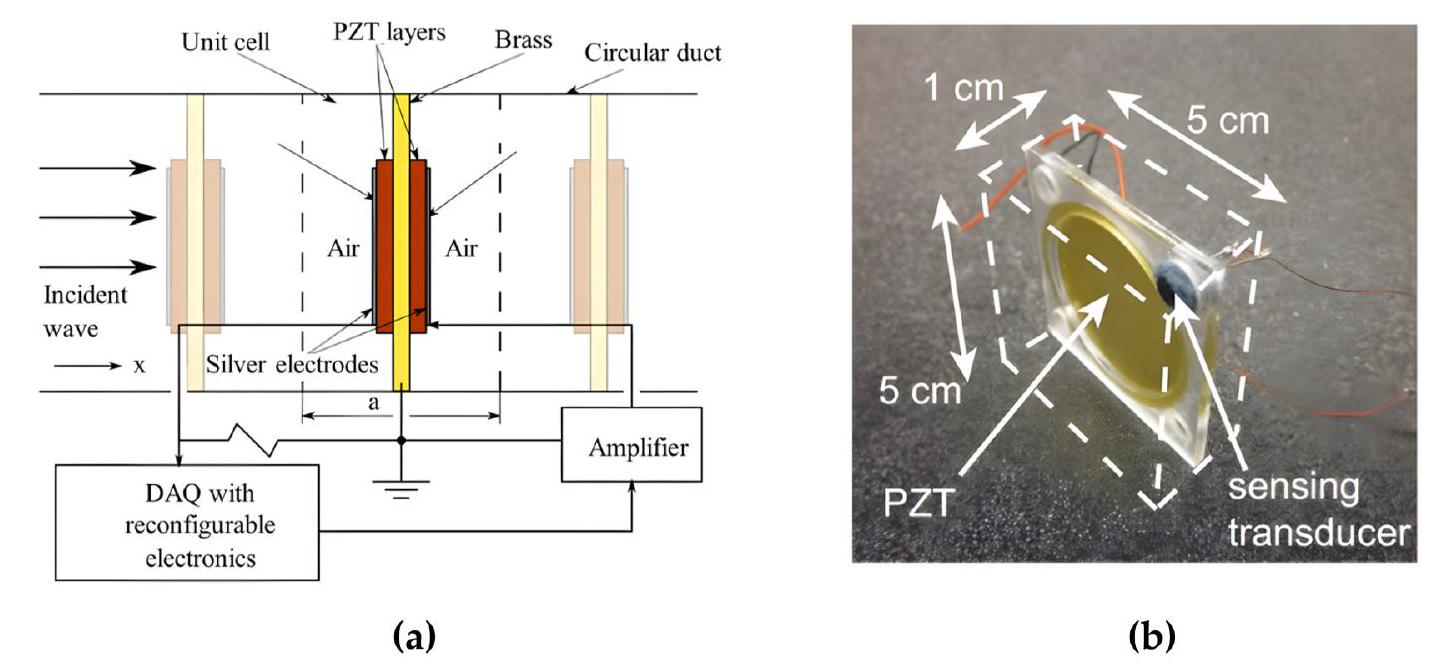

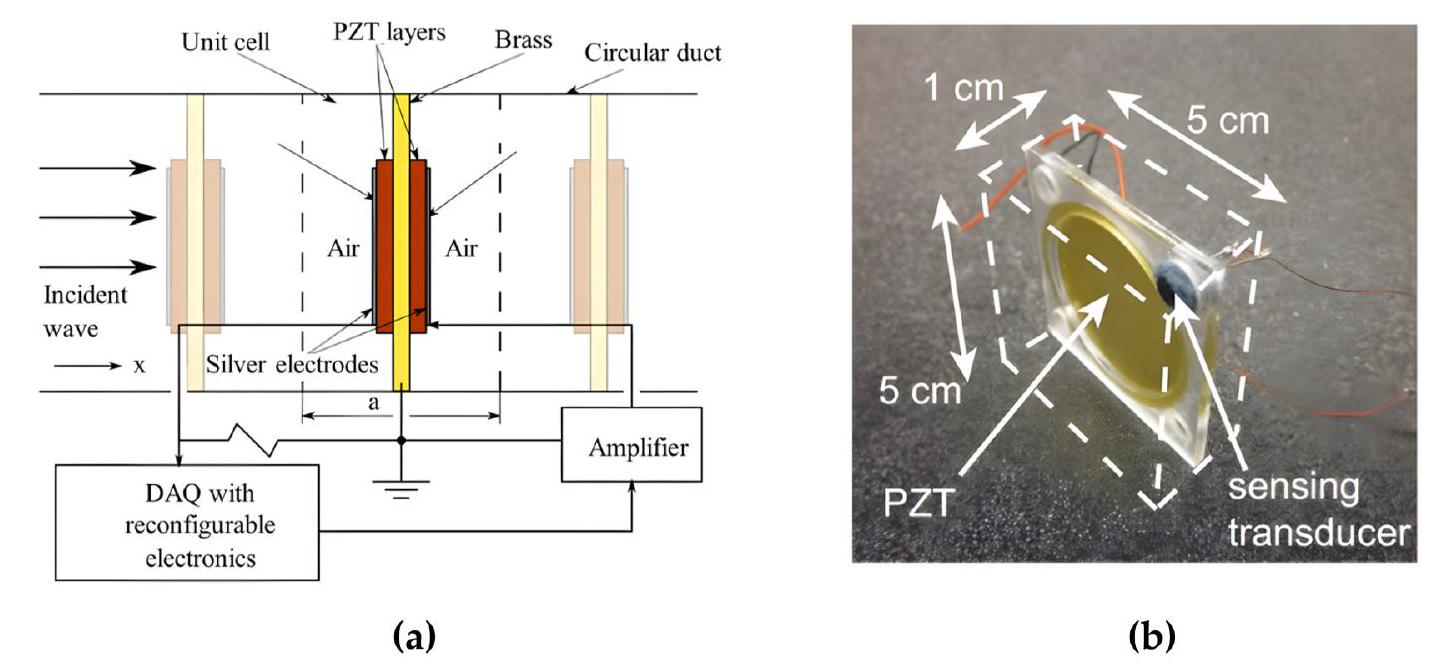

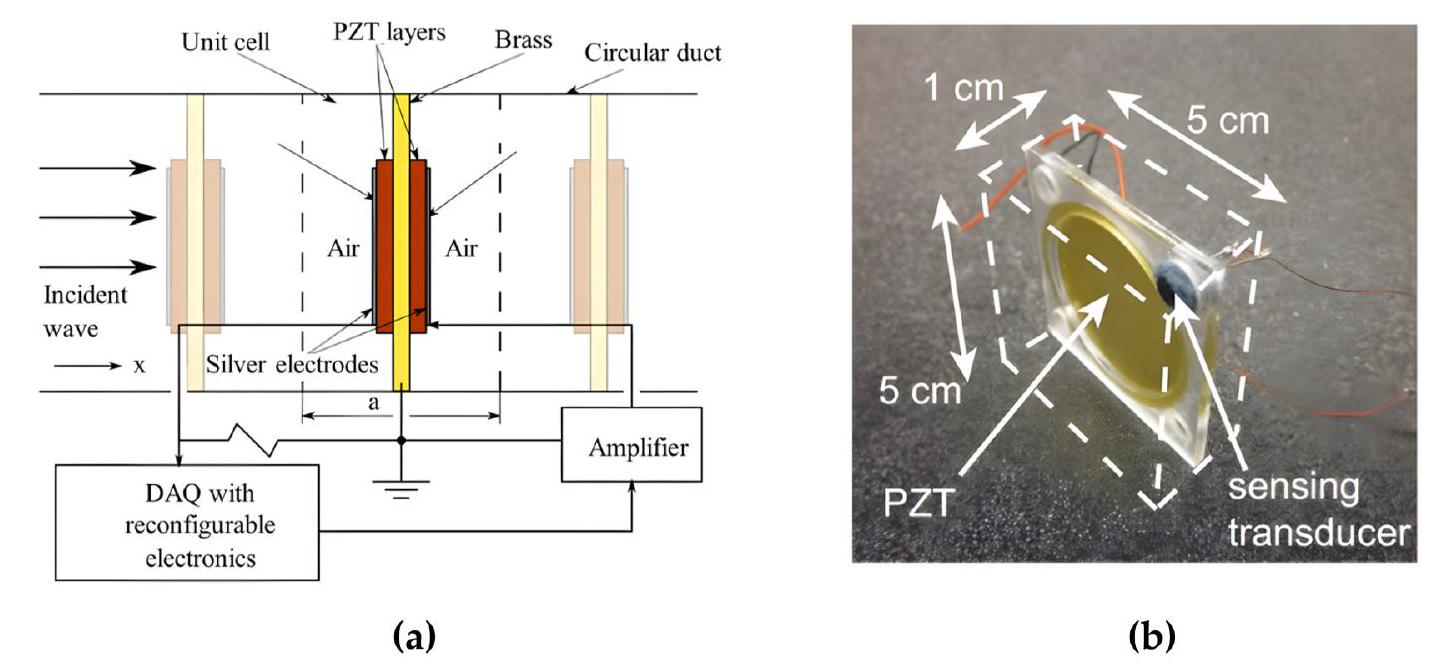

5.2. Tunable acoustic metamaterials

5.3. Membrane type passive acoustic metamaterials

5.4. Plate like acoustic metamaterials

membrane type architecture, the latter is affected by the tension in the membrane which changes over repeated use limiting their applications in areas that require long term installation. In this regard, metamaterials featuring the plate type architecture may offer a higher likelihood for noise-reduction in buildings. A light weight ultrathin plate type acoustic metamaterial architecture consisting of nylon plate and elastic ethylenevinyl acetate copolymer was designed by Ma et al. [105]. The data revealed the plate type architecture to offer improved sound reduction along the low frequencies. According to Varanasi et al. [131], the plate-type metamaterials were found to possess a superior sound reduction index, as evidenced by a periodic array of unit cells comprising plates that are held within a grid-like framework, as shown in Fig. 18a. This design is slender and devoid of weighty resonating or restrictive elements that restrict its application. This plate-type metamaterial structure is also ideally suited for noise control applications where the goal is to minimize treatment mass while achieving a specified

6. Ventilated acoustic metamaterials

considering type of building walls, windows and ventilation being treated. Nevertheless, for practical large-scale implementation of acoustic metamaterials for building acoustics, there is a need for continued development of lightweight load-bearing structures that possess remarkable strength and longevity [93].

7. Prospects and challenges of metamaterials in building insulation

7.1. Low frequency noise mitigation

7.2. Targeted sound insulation

7.3. Multiple acoustic metamaterials into a single architecture

7.4. Low-cost manufacturing and scale up are key barriers

of metamaterials and the verification of complex designs have been made possible by advances in 3D printing technology. On the other hand, due of the lack of robustness in fabrication processes, sizes, and material qualities, process optimisation and sustainability for 3D printing technology remain significant challenges. For instance, prestressing pressures that are challenging to modify and sustain over an extended period of time may have an impact on certain features for the majority of membrane-type AMMs. The majority of membrane-type AMMs are now produced manually and necessitate a wide range of materials with various qualities, which unfortunately results in a loss of uniformity. For AMM technology to be used in real applications, therefore, more sophisticated manufacturing techniques must be developed [150].

7.5. Control of structural borne sound within buildings

structural capacity, imposed extra mass, and the range of attenuated frequency bands. In an effort to better understand sound mitigation applications, Assouar et al. [156] conducted theoretical and numerical assessments of the behaviour of a plate-type acoustic metamaterial in an airborne sound environment. Two configurations were taken into consideration: one based on pillars and the other on springs and mass. They have demonstrated that the examined metamaterial may generate a significant sound transmission loss (STL) in the sonic frequency range, indicating that the system is very appropriate and efficient for applications involving the mitigation of sound and vibration. Furthermore, they proposed that the plate-type metamaterial can be a potential way to get around the coincidence frequency constraint, which results in high sound transmission via plates for sound shielding, by employing carefully selected low-frequency resonators.

8. Conclusions

CRediT authorship contribution statement

analysis, Conceptualization. Aaron Vance: Writing – review & editing, Methodology, Investigation, Formal analysis, Conceptualization. Abul Arafat: Writing – review & editing, Methodology, Investigation, Formal analysis, Conceptualization.

Declaration of competing interest

Data availability

References

[2] A. Arjunan, A. Baroutaji, A.S. Praveen, A.G. Olabi, C.J. Wang, Acoustic performance of metallic foams, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2019, https://doi.org/10.1016/B978-0-12-803581-8.11561-9.

[3] M.H. Lu, L. Feng, Y.F. Chen, Phononic crystals and acoustic metamaterials, Mater. Today 12 (2009) 34-42, https://doi.org/10.1016/S1369-7021(09)70315-3.

[4] K.J.B. Lee, M.K. Jung, S.H. Lee, Highly tunable acoustic metamaterials based on a resonant tubular array, Phys. Rev. B Condens. Matter (2012), https://doi.org/ 10.1103/PhysRevB.86.184302.

[5] X. Zhang, Z. Qu, H. Wang, Engineering Acoustic Metamaterials for Sound Absorption: from Uniform to Gradient Structures, Elsevier Inc., 2020, https://doi. org/10.1016/j.isci.2020.101110.

[6] S.A. Cummer, J. Christensen, A. Alù, Controlling sound with acoustic metamaterials, Nat. Rev. Mater. 1 (2016), https://doi.org/10.1038/ natrevmats.2016.1.

[7] G. Ma, P. Sheng, Acoustic metamaterials: from local resonances to broad horizons, Sci. Adv. 2 (2016), https://doi.org/10.1126/sciadv. 1501595.

[8] V. Fedotov, Metamaterials, Springer Handbooks, 2017, https://doi.org/10.1007/ 978-3-319-48933-9_56.

[9] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, V.B. Nguyen, M. English, Sound frequency dependent mesh modelling to simulate the acoustic insulation of stud based double-leaf walls, in: Proc. ISMA 2014 – Int. Conf. Noise Vib. Eng. USD 2014 – Int. Conf. Uncertain, Struct. Dyn., 2014.

[10] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, V.B. Nguyen, M. English, Development of a 3D finite element acoustic model to predict the sound reduction index of stud based double-leaf walls, J. Sound Vib. 333 (2014) 6140-6155, https://doi.org/10.1016/j.jsv.2014.06.032.

[11] G. Ji, J. Huber, Recent progress in acoustic metamaterials and active piezoelectric acoustic metamaterials – a review, Appl. Mater. Today 26 (2022) 101260, https:// doi.org/10.1016/j.apmt.2021.101260.

[12] P.F. Pai, G. Huang, S. of, Photo-optical Instrumentation Engineers, Theory and Design of Acoustic Metamaterials, 2015. https://books.google.co.uk/books?id =EIdRjwEACAAJ.

[13] V. Romero-Garcia, A.C. Hladky-Hennion, Fundamentals and Applications of Acoustic Metamaterials: from Seismic to Radio Frequency, Wiley, 2019. https: //books.google.co.uk/books?id=CvulDwAAQBAJ.

[14] Z. Chen, B. Guo, Y. Yang, C. Cheng, Metamaterials-based enhanced energy harvesting: a review, Phys. B Condens. Matter (2014), https://doi.org/10.1016/j. physb.2013.12.040.

[15] N. Kaina, F. Lemoult, M. Fink, G. Lerosey, Negative refractive index and acoustic superlens from multiple scattering in single negative metamaterials, Nature (2015), https://doi.org/10.1038/nature14678.

[16] L. Terrenoir, J. Lartigau, A. Arjunan, L. Laguna Salvado, C. Merlo, Influence of wire feed speed and torch speed on the mechanical properties of wire arc additively manufactured stainless steel, J. Manuf. Sci. Eng. 145 (2023) 101012, https://doi.org/10.1115/1.4063108.

[17] A. Cano-Vicent, M.M. Tambuwala, S.S. Hassan, D. Barh, A.A.A. Aljabali, M. Birkett, A. Arjunan, Á. Serrano-Aroca, Fused deposition modelling: current status, methodology, applications and future prospects, Addit. Manuf. 47 (2021) 102378, https://doi.org/10.1016/j.addma.2021.102378.

[18] A. Arjunan, A. Baroutaji, J. Robinson, Advances in acoustic metamaterials, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2021, https://doi.org/10.1016/ B978-0-12-815732-9.00091-7.

[19] Z. Yang, J. Mei, M. Yang, N.H. Chan, P. Sheng, Membrane-type acoustic metamaterial with negative dynamic mass, Phys. Rev. Lett. (2008), https://doi. org/10.1103/PhysRevLett.101.204301.

[20] T.J. Cox, P. D’Antonio, Acoustic Absorbers and Diffusers : Theory, Design and Application, Taylor & Francis Group, Boca Raton, 2016.

[21] Y. Tao, M. Ren, H. Zhang, T. Peijs, Recent progress in acoustic materials and noise control strategies – a review, Appl. Mater. Today 24 (2021) 101141, https://doi. org/10.1016/j.apmt.2021.101141.

[22] Z. Sü, S. Yilmazer, The acoustical characteristics of the kocatepe mosque in ankara, Turkey, Architect. Sci. Rev. 51 (2008) 21-30, https://doi.org/10.3763/ asre.2008.5104.

[23] Z. Sü, M. Çalışkan, Acoustical design and noise control in metro stations: case studies of the ankara metro system, Build. Acoust. 14 (2007) 203-221, https:// doi.org/10.1260/135101007781998910.

[24] X. Peng, J. Ji, Y. Jing, Composite honeycomb metasurface panel for broadband sound absorption, J. Acoust. Soc. Am. (2018), https://doi.org/10.1121/ 1.5055847.

[25] J. Mei, G. Ma, M. Yang, Z. Yang, W. Wen, P. Sheng, Dark acoustic metamaterials as super absorbers for low-frequency sound, Nat. Commun. 3 (2012), https://doi. org/10.1038/ncomms1758.

[26] Y. Du, W. Wu, W. Chen, Y. Lin, Q. Chi, Control the structure to optimize the performance of sound absorption of acoustic metamaterial: a review, AIP Adv. 11 (2021).

[27] K. Steiger, Control of Static and Dynamic Mechanical Response of Piezoelectric Composite Shells: Applications to Acoustics and Adaptive Optics, 2013, https:// doi.org/10.13140/RG.2.1.2731.1120.

[29] C.J. Naify, C.-M. Chang, G. McKnight, F. Scheulen, S. Nutt, Membrane-type metamaterials: transmission loss of multi-celled arrays, J. Appl. Phys. 109 (2011) 104902, https://doi.org/10.1063/1.3583656.

[30] Analytic Modeling of Sound Transmission through Membrane-Type Acoustic Metamaterials – M.C. Gill Composites Center, (n.d.). https://composites.usc.edu/ 2018/04/03/soundtransmissionthroughmembrane/(accessed August 31, 2022).

[31] Y.-Z. Wang, L. Ma, Sound insulation performance of membrane-type metamaterials combined with pyramidal truss core sandwich structure, Compos. Struct. 260 (2021) 113257.

[32] F. Ma, C. Wang, C. Liu, J.H. Wu, Structural designs, principles, and applications of thin-walled membrane and plate-type acoustic/elastic metamaterials, J. Appl. Phys. 129 (2021).

[33] C.R. Fuller, G. Mathur, Poro-elastic acoustic meta materials, in: INTER-NOISE NOISE-CON Congr. Conf. Proc., Institute of Noise Control Engineering, 2017, pp. 1581-1590.

[34] X. Sagartzazu, L. Hervella-Nieto, J.M. Pagalday, Review in sound absorbing materials, Arch. Comput. Methods Eng. 15 (2008) 311-342.

[35] J. Landaluze, I. Portilla, J.M. Pagalday, A. Martínez, R. Reyero, Application of active noise control to an elevator cabin, Control Eng. Pract. 11 (2003) 1423-1431.

[36] M. Cuesta, P. Cobo, A. Fernández, J. Pfretzschner, Using a thin actuator as secondary source for hybrid passive/active absorption in an impedance tube, Appl. Acoust. 67 (2006) 15-27.

[37] W.H. Organization, Environmental Noise Guidelines for the European Region, World Health Organization. Regional Office for Europe, 2018.

[38] A. Arjunan, C. Wang, M. English, M. Stanford, P. Lister, A computationallyefficient numerical model to characterize the noise behavior of metal-framed walls, Metals 5 (2015) 1414-1431, https://doi.org/10.3390/met5031414.

[39] A. Arjunan, J. Rackley, M. Stanford, Experimental investigation on the sound reduction performance of frequency controlled acoustic interference cavities, in: Proc. INTER-NOISE 2016-45th Int. Congr. Expo. Noise Control Eng. Towar. A Quieter Futur., 2016.

[40] H.H. Huang, C.T. Sun, G.L. Huang, On the negative effective mass density in acoustic metamaterials, Int. J. Eng. Sci. (2009), https://doi.org/10.1016/j. ijengsci.2008.12.007.

[41] M.R. Haberman, M.D. Guild, Acoustic metamaterials, Phys. Today (2016), https://doi.org/10.1063/PT.3.3198.

[42] M. Caleap, B.W. Drinkwater, P.D. Wilcox, Effective dynamic constitutive parameters of acoustic metamaterials with random microstructure, New J. Phys. 14 (2012) 33014, https://doi.org/10.1088/1367-2630/14/3/033014.

[43] P. Sheng, J. Mei, Z. Liu, W. Wen, Dynamic mass density and acoustic metamaterials, Phys. B Condens. Matter (2007), https://doi.org/10.1016/j. physb.2006.12.046.

[44] M.I. Hussein, M.J. Frazier, Damped Phononic Crystals and Acoustic Metamaterials, 2013, https://doi.org/10.1007/978-3-642-31232-8_6.

[45] M.F. Ponge, O. Poncelet, D. Torrent, Dynamic homogenization theory for nonlocal acoustic metamaterials, Extrem. Mech. Lett. (2017), https://doi.org/ 10.1016/j.eml.2016.10.006.

[46] C. Coulais, D. Sounas, A. Alù, Static non-reciprocity in mechanical metamaterials, Nature (2017), https://doi.org/10.1038/nature21044.

[47] M. Kadic, T. Bückmann, R. Schittny, M. Wegener, Metamaterials beyond electromagnetism, Rep. Prog. Phys. (2013), https://doi.org/10.1088/0034-4885/ 76/12/126501.

[48] J. Liu, H. Guo, T. Wang, A review of acoustic metamaterials and phononic crystals, Crystals (2020), https://doi.org/10.3390/cryst10040305.

[49] X. Zhou, X. Liu, G. Hu, Elastic metamaterials with local resonances: an overview, Theor. Appl. Mech. Lett. (2012), https://doi.org/10.1063/2.1204101.

[50] V. Fokin, M. Ambati, C. Sun, X. Zhang, Method for retrieving effective properties of locally resonant acoustic metamaterials, Phys. Rev. B Condens. Matter (2007), https://doi.org/10.1103/PhysRevB.76.144302.

[51] S. Kumar, H. Lee, The present and future role of acoustic metamaterials for architectural and urban noise mitigations, Acoustics (2019), https://doi.org/ 10.3390/acoustics1030035.

[52] M.D. Guild, V.M. García-Chocano, W. Kan, J. Sánchez-Dehesa, Acoustic metamaterial absorbers based on multilayered sonic crystals, J. Appl. Phys. (2015), https://doi.org/10.1063/1.4915346.

[53] Y. Tang, S. Ren, H. Meng, F. Xin, L. Huang, T. Chen, C. Zhang, T.J. Lu, Hybrid acoustic metamaterial as super absorber for broadband low-frequency sound, Sci. Rep. (2017), https://doi.org/10.1038/srep43340.

[54] T. Lee, T. Nomura, E.M. Dede, H. Iizuka, Ultrasparse acoustic absorbers enabling fluid flow and visible-light controls, Phys. Rev. Appl. (2019), https://doi.org/ 10.1103/PhysRevApplied.11.024022.

[55] A.C. Slagle, C.R. Fuller, Low frequency noise reduction using poro-elastic acoustic metamaterials, in: 21st AIAA/CEAS Aeroacoustics Conf, 2015, https://doi.org/ 10.2514/6.2015-3113.

[56] X. Jiang, B. Liang, R.Q. Li, X.Y. Zou, L.L. Yin, J.C. Cheng, Ultra-broadband absorption by acoustic metamaterials, Appl. Phys. Lett. (2014), https://doi.org/ 10.1063/1.4904887.

[57] S. Ebrahimi-Nejad, M. Kheybari, Honeycomb locally resonant absorbing acoustic metamaterials with stop band behavior, Mater. Res. Express (2018), https://doi. org/10.1088/2053-1591/aadbe2.

[58] S. Cho, B. Kim, D. Min, J. Kang, J. Park, Acoustic metamaterial panel composed of funnel-shaped cell unit having multi-band negative material properties, in: INTERNOISE 2014-43rd Int. Congr. Noise Control Eng. Improv, World Through Noise Control, 2014.

[59] J. Niu, J. Wu, Low frequency wide band sound absorption performance of asymmetric type acoustic metamaterials, Zhendong Yu Chongji/Journal Vib. Shock. (2018), https://doi.org/10.13465/j.cnki.jvs.2018.19.007.

[60] S. Ortiz, C. Gonzalez, P. Cobo, F. Montero de Espinosa, Attenuating open cavity tones by lining its walls with microperforated panels, Noise Control Eng. J. 62 (2014) 145-151, https://doi.org/10.3397/1/376215.

[61] J. Pfretzschner, P. Cobo, F. Simón, M. Cuesta, A. Fernández, Microperforated insertion units: an alternative strategy to design microperforated panels, Appl. Acoust. 67 (2006) 62-73, https://doi.org/10.1016/j.apacoust.2005.05.005.

[62] S. Greiner, K. Wudy, L. Lanzl, D. Drummer, Selective laser sintering of polymer blends: bulk properties and process behavior, Polym. Test. 64 (2017) 136-144, https://doi.org/10.1016/j.polymertesting.2017.09.039.

[63] A. Arjunan, M. Demetriou, A. Baroutaji, C. Wang, Mechanical performance of highly permeable laser melted Ti6Al4V bone scaffolds, J. Mech. Behav. Biomed. Mater. 102 (2020) 103517, https://doi.org/10.1016/j.jmbbm.2019.103517.

[64] A. Arjunan, Acoustic absorption of passive destructive interference cavities, Mater. Today Commun. 19 (2019) 68-75, https://doi.org/10.1016/j. mtcomm.2018.12.012.

[65] A. Arjunan, Targeted sound attenuation capacity of 3D printed noise cancelling waveguides, Appl. Acoust. 151 (2019) 30-44, https://doi.org/10.1016/j. apacoust.2019.03.008.

[67] H. Xie, Y. Lyu, Sound absorption characteristics of the perforated panel resonator with tube bundles, 21st Int. Congr. Sound Vib. (2014), Volume 1, pp. 5010, ICSV 2014, 2014.

[68] X. Wang, Y. Chen, G. Zhou, T. Chen, F. Ma, Synergetic coupling large-scale platetype acoustic metamaterial panel for broadband sound insulation, J. Sound Vib. (2019), https://doi.org/10.1016/j.jsv.2019.114867.

[69] S.W. Ren, L. Van Belle, C. Claeys, F.X. Xin, T.J. Lu, E. Deckers, W. Desmet, Improvement of the sound absorption of flexible micro-perforated panels by local resonances, Mech. Syst. Signal Process. (2019), https://doi.org/10.1016/j. ymssp.2018.07.046.

[70] T.A. Starkey, J.D. Smith, A.P. Hibbins, J.R. Sambles, H.J. Rance, Thin structured rigid body for acoustic absorption, Appl. Phys. Lett. (2017), https://doi.org/ 10.1063/1.4974487.

[71] L.J. Li, B. Zheng, L.M. Zhong, J. Yang, B. Liang, J.C. Cheng, Broadband compact acoustic absorber with high-efficiency ventilation performance, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5038184.

[72] S. Huang, X. Fang, X. Wang, B. Assouar, Q. Cheng, Y. Li, Acoustic perfect absorbers via Helmholtz resonators with embedded apertures, J. Acoust. Soc. Am. (2019), https://doi.org/10.1121/1.5087128.

[73] C.R. Liu, J.H. Wu, X. Chen, F. Ma, A thin low-frequency broadband metasurface with multi-order sound absorption, J. Phys. D Appl. Phys. (2019), https://doi. org/10.1088/1361-6463/aafaa3.

[74] A.A. Fernández-Marín, N. Jiménez, J.P. Groby, J. Sánchez-Dehesa, V. RomeroGarcía, Aerogel-based metasurfaces for perfect acoustic energy absorption, Appl. Phys. Lett. (2019), https://doi.org/10.1063/1.5109084.

[75] X. Cai, Q. Guo, G. Hu, J. Yang, Ultrathin low-frequency sound absorbing panels based on coplanar spiral tubes or coplanar Helmholtz resonators, Appl. Phys. Lett. 105 (2014) 121901, https://doi.org/10.1063/1.4895617.

[76] S. Huang, X. Fang, X. Wang, B. Assouar, Q. Cheng, Y. Li, Acoustic perfect absorbers via spiral metasurfaces with embedded apertures, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5063289.

[77] G. Ma, M. Yang, S. Xiao, Z. Yang, P. Sheng, Acoustic metasurface with hybrid resonances, Nat. Mater. 13 (2014) 873-878, https://doi.org/10.1038/nmat3994.

[78] Y. Aurégan, Ultra-thin low frequency perfect sound absorber with high ratio of active area, Appl. Phys. Lett. 113 (2018) 201904, https://doi.org/10.1063/ 1.5063504.

[79] X. Wang, X. Luo, H. Zhao, Z. Huang, Acoustic perfect absorption and broadband insulation achieved by double-zero metamaterials, Appl. Phys. Lett. 112 (2018) 21901, https://doi.org/10.1063/1.5018180.

[80] C. Xu, H. Guo, Y. Chen, X. Dong, H. Ye, Y. Wang, Study on broadband lowfrequency sound insulation of multi-channel resonator acoustic metamaterials, AIP Adv. 11 (2021) 45321, https://doi.org/10.1063/5.0047416.

[81] F. Zangeneh-Nejad, R. Fleury, Active times for acoustic metamaterials, Rev. Phys. 4 (2019) 100031, https://doi.org/10.1016/j.revip.2019.100031.

[82] A. Arjunan, A. Baroutaji, J. Robinson, C. Wang, Characteristics of acoustic metamaterials, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier, 2021, https:// doi.org/10.1016/B978-0-12-815732-9.00090-5.

[83] A. Arjunan, A. Baroutaji, A. Latif, Acoustic behaviour of 3D printed titanium perforated panels, Results Eng 11 (2021) 100252, https://doi.org/10.1016/j. rineng.2021.100252.

[84] Y. Li, B.M. Assouar, Acoustic metasurface-based perfect absorber with deep subwavelength thickness, Appl. Phys. Lett. 108 (2016) 63502, https://doi.org/ 10.1063/1.4941338.

[85] X.H. Zhang, Z.G. Qu, X.C. He, D.L. Lu, Experimental study on the sound absorption characteristics of continuously graded phononic crystals, AIP Adv. 6 (2016) 105205, https://doi.org/10.1063/1.4965923.

[86] A. Climente, D. Torrent, J. Sánchez-Dehesa, Omnidirectional broadband acoustic absorber based on metamaterials, Appl. Phys. Lett. 100 (2012), https://doi.org/ 10.1063/1.3701611.

[87] J. Xu, S. Xiao, P. He, Y. Wang, Y. Shen, L. Hong, Y. Luo, B. He, Realization of broadband truly rainbow trapping in gradient-index metamaterials, Opt Express 30 (2022) 3941-3953.

[88] Z.-Y. Li, T.-X. Ma, Y.-Z. Wang, F.-M. Li, C. Zhang, Vibration isolation by novel meta-design of pyramid-core lattice sandwich structures, J. Sound Vib. 480 (2020) 115377.

[89] Y. Xu, Y. Fu, H. Chen, Planar gradient metamaterials, Nat. Rev. Mater. 1 (2016), https://doi.org/10.1038/natrevmats.2016.67.

[90] J. Zhu, Y. Chen, X. Zhu, F.J. Garcia-Vidal, X. Yin, W. Zhang, X. Zhang, Acoustic rainbow trapping, Sci. Rep. 3 (2013) 1728, https://doi.org/10.1038/srep01728.

[91] M. Alshaqaq, C. Sugino, A. Erturk, Programmable rainbow trapping and band-gap enhancement via spatial group-velocity tailoring in elastic metamaterials, Phys. Rev. Appl. 17 (2022) L021003, https://doi.org/10.1103/PhysRevApplied.17. L021003.

[92] X. Ni, Y. Wu, Z.-G. Chen, L.-Y. Zheng, Y.-L. Xu, P. Nayar, X.-P. Liu, M.-H. Lu, Y.F. Chen, Acoustic rainbow trapping by coiling up space, Sci. Rep. 4 (2014) 7038, https://doi.org/10.1038/srep07038.

[93] N. Gao, Z. Zhang, J. Deng, X. Guo, B. Cheng, H. Hou, Acoustic Metamaterials for Noise Reduction: A Review, Adv. Mater. Technol. n/a (n.d.) 2100698. https://d oi.org/10.1002/admt. 202100698.

[94] W. Akl, A. Baz, Experimental characterization of active acoustic metamaterial cell with controllable dynamic density, J. Appl. Phys. 112 (2012) 84912, https://doi. org/10.1063/1.4759327.

[95] J. Zhao, X. Li, Y. Wang, W. Wang, B. Zhang, X. Gai, Membrane acoustic metamaterial absorbers with magnetic negative stiffness, J. Acoust. Soc. Am. 141 (2017) 840-846, https://doi.org/10.1121/1.4976042.

[96] X. Li, T. Xing, J. Zhao, X. Gai, Broadband low frequency sound absorption using a monostable acoustic metamaterial, J. Acoust. Soc. Am. 147 (2020), https://doi. org/10.1121/10.0000714. EL113-EL118.

[97] X. Xiang, H. Tian, Y. Huang, X. Wu, W. Wen, Manually tunable ventilated metamaterial absorbers, Appl. Phys. Lett. 118 (2021) 53504, https://doi.org/ 10.1063/5.0037547.

[98] Z. Xu, H. Meng, A. Chen, J. Yang, B. Liang, J. Cheng, Tunable low-frequency and broadband acoustic metamaterial absorber, J. Appl. Phys. 129 (2021) 94502, https://doi.org/10.1063/5.0038940.

[99] J. Du, Y. Luo, X. Zhao, X. Sun, Y. Song, X. Hu, Bilayer ventilated labyrinthine metasurfaces with high sound absorption and tunable bandwidth, Sci. Rep. 11 (2021) 5829, https://doi.org/10.1038/s41598-021-84986-0.

[100] A. Arjunan, C.J. Wang, K. Yahiaoui, D.J. Mynors, T. Morgan, M. English, Finite element acoustic analysis of a steel stud based double-leaf wall, Build. Environ. 67 (2013) 202-210, https://doi.org/10.1016/j.buildenv.2013.05.021.

[101] J. Li, X. Zhou, G. Huang, G. Hu, Acoustic metamaterials capable of both sound insulation and energy harvesting, Smart Mater. Struct. (2016), https://doi.org/ 10.1088/0964-1726/25/4/045013.

[102] C.J. Naify, C.M. Chang, G. McKnight, S. Nutt, Transmission loss and dynamic response of membrane-type locally resonant acoustic metamaterials, J. Appl. Phys. (2010), https://doi.org/10.1063/1.3514082.

[103] M. Yang, G. Ma, Z. Yang, P. Sheng, Coupled membranes with doubly negative mass density and bulk modulus, Phys. Rev. Lett. (2013), https://doi.org/ 10.1103/PhysRevLett.110.134301.

[104] S. Kumar, P. Bhushan, O. Prakash, S. Bhattacharya, Double negative acoustic metastructure for attenuation of acoustic emissions, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5022602.

[105] F. Ma, M. Huang, J.H. Wu, Ultrathin lightweight plate-type acoustic metamaterials with positive lumped coupling resonant, J. Appl. Phys. (2017), https://doi.org/10.1063/1.4972839.

[106] F. Ma, M. Huang, Y. Xu, J.H. Wu, Bi-layer plate-Type acoustic metamaterials with Willis coupling, J. Appl. Phys. (2018), https://doi.org/10.1063/1.4991426.

[107] L.Y.L. Ang, Y.K. Koh, H.P. Lee, Plate-type acoustic metamaterial with cavities coupled via an orifice for enhanced sound transmission loss, Appl. Phys. Lett. (2018), https://doi.org/10.1063/1.5019602.

[108] A. Arjunan, A. Foteinou, A comparative study on the acoustic behaviour of freestanding curved and flat single panel screens in an open-plan enclosed environment, in: INTER-NOISE 2017-46th Int. Congr. Expo. Noise Control Eng, Taming Noise Mov. Quiet, 2017.

[109] Z. Li, D.Q. Yang, S.L. Liu, S.Y. Yu, M.H. Lu, J. Zhu, S.T. Zhang, M.W. Zhu, X. S. Guo, H.D. Wu, X.L. Wang, Y.F. Chen, Broadband gradient impedance matching using an acoustic metamaterial for ultrasonic transducers, Sci. Rep. (2017), https://doi.org/10.1038/srep42863.

[110] F. Casadei, T. Delpero, A. Bergamini, P. Ermanni, M. Ruzzene, Piezoelectric resonator arrays for tunable acoustic waveguides and metamaterials, J. Appl. Phys. (2012), https://doi.org/10.1063/1.4752468.

[111] S.B. Chen, J.H. Wen, G. Wang, X. Sen Wen, Tunable band gaps in acoustic metamaterials with periodic arrays of resonant shunted piezos, Chin. Phys. B (2013), https://doi.org/10.1088/1674-1056/22/7/074301.

[112] A. Allam, A. Elsabbagh, W. Akl, Modeling and design of two-dimensional membrane-type active acoustic metamaterials with tunable anisotropic density, J. Acoust. Soc. Am. (2016), https://doi.org/10.1121/1.4966627.

[113] W. Akl, A. Baz, Multi-cell active acoustic metamaterial with programmable bulk modulus, J. Intell. Mater. Syst. Struct. (2010), https://doi.org/10.1177/ 1045389X09359434.

[114] L. Airoldi, M. Ruzzene, Design of tunable acoustic metamaterials through periodic arrays of resonant shunted piezos, New J. Phys. (2011), https://doi.org/10.1088/ 1367-2630/13/11/113010.

[115] C. Sugino, S. Leadenham, M. Ruzzene, A. Erturk, An investigation of electroelastic bandgap formation in locally resonant piezoelectric metastructures, Smart Mater. Struct. (2017), https://doi.org/10.1088/1361-665X/aa6671.

[116] F. Casadei, M. Ruzzene, L. Dozio, K.A. Cunefare, Broadband vibration control through periodic arrays of resonant shunts: experimental investigation on plates, Smart Mater. Struct. (2010), https://doi.org/10.1088/0964-1726/19/1/015002.

[117] S. Chen, Y. Fan, Q. Fu, H. Wu, Y. Jin, J. Zheng, F. Zhang, A review of tunable acoustic metamaterials, Appl. Sci. (2018), https://doi.org/10.3390/app8091480.

[118] A. Allam, A. Elsabbagh, W. Akl, Experimental demonstration of one-dimensional active plate-type acoustic metamaterial with adaptive programmable density, J. Appl. Phys. (2017), https://doi.org/10.1063/1.4979020.

[119] B.I. Popa, L. Zigoneanu, S.A. Cummer, Tunable active acoustic metamaterials, Phys. Rev. B Condens. Matter (2013), https://doi.org/10.1103/ PhysRevB.88.024303.

[120] P. Wang, F. Casadei, S. Shan, J.C. Weaver, K. Bertoldi, Harnessing buckling to design tunable locally resonant acoustic metamaterials, Phys. Rev. Lett. (2014), https://doi.org/10.1103/PhysRevLett.113.014301.

[121] Z. Yang, H.M. Dai, N.H. Chan, G.C. Ma, P. Sheng, Acoustic metamaterial panels for sound attenuation in the

[122] Y. Zhang, J. Wen, Y. Xiao, X. Wen, J. Wang, Theoretical investigation of the sound attenuation of membrane-type acoustic metamaterials, Phys. Lett. 376 (2012) 1489-1494, https://doi.org/10.1016/j.physleta.2012.03.010.

[123] Y. Chen, G. Huang, X. Zhou, G. Hu, C.-T. Sun, Analytical coupled vibroacoustic modeling of membrane-type acoustic metamaterials: membrane model, J. Acoust. Soc. Am. 136 (2014) 969-979, https://doi.org/10.1121/1.4892870.

[124] C.J. Naify, C.-M. Chang, G. McKnight, S. Nutt, Transmission loss of membranetype acoustic metamaterials with coaxial ring masses, J. Appl. Phys. 110 (2011) 124903, https://doi.org/10.1063/1.3665213.

[125] H. Tian, X. Wang, Y. Zhou, Theoretical model and analytical approach for a circular membrane-ring structure of locally resonant acoustic metamaterial, Appl. Phys. A 114 (2014) 985-990, https://doi.org/10.1007/s00339-013-8047-y.

[126] C.J. Naify, C.-M. Chang, G. McKnight, S.R. Nutt, Scaling of membrane-type locally resonant acoustic metamaterial arrays, J. Acoust. Soc. Am. 132 (2012) 2784-2792, https://doi.org/10.1121/1.4744941.

[127] N. Sui, X. Yan, T.-Y. Huang, J. Xu, F.-G. Yuan, Y. Jing, A lightweight yet soundproof honeycomb acoustic metamaterial, Appl. Phys. Lett. 106 (2015) 171905, https://doi.org/10.1063/1.4919235.

[128] X. Wang, H. Zhao, X. Luo, Z. Huang, Membrane-constrained acoustic metamaterials for low frequency sound insulation, Appl. Phys. Lett. 108 (2016) 41905, https://doi.org/10.1063/1.4940717.

[129] J. Jin Park, J.-H. Kwak, K. Song, Ultraslow medium with an acoustic membranelike undamped dynamic vibration absorber for low-frequency isolation, Extrem. Mech. Lett. 43 (2021) 101203, https://doi.org/10.1016/j.eml.2021.101203.

[130] F. Langfeldt, W. Gleine, Design of acoustic partitions with thin plate-like acoustic metamaterials, in: Proc. Int. Congr. Acoust., 23rd International Congress on Acoustics, 2019, pp. 4870-4877, https://doi.org/10.18154/RWTH-CONV239261. Achen, Germany.

[131] S. Varanasi, J.S. Bolton, T.H. Siegmund, R.J. Cipra, The low frequency performance of metamaterial barriers based on cellular structures, Appl. Acoust. 74 (2013) 485-495, https://doi.org/10.1016/j.apacoust.2012.09.008.

[132] L.Y.L. Ang, Y.K. Koh, H.P. Lee, Plate-type acoustic metamaterials: evaluation of a large-scale design adopting modularity for customizable acoustical performance, Appl. Acoust. 149 (2019) 156-170, https://doi.org/10.1016/j. apacoust.2019.01.027.

[133] Q. Lin, Q. Lin, Y. Wang, G. Di, Sound insulation performance of sandwich structure compounded with a resonant acoustic metamaterial, Compos. Struct. 273 (2021) 114312, https://doi.org/10.1016/j.compstruct.2021.114312.

[134] C. Gazzola, S. Caverni, A. Corigliano, From mechanics to acoustics: critical assessment of a robust metamaterial for acoustic insulation application, Appl. Acoust. 183 (2021) 108311, https://doi.org/10.1016/j.apacoust.2021.108311.

[135] M.H.F.H.F. De Salis, D.J.J. Oldham, S. Sharples, Noise control strategies for naturally ventilated buildings, Build. Environ. 37 (2002) 471-484, https://doi. org/10.1016/S0360-1323(01)00047-6.

[136] S.-H. Kim, S.-H. Lee, Air transparent soundproof window, AIP Adv. 4 (2014) 117123, https://doi.org/10.1063/1.4902155.

[137] X. Yu, Z. Lu, L. Cheng, F. Cui, On the sound insulation of acoustic metasurface using a sub-structuring approach, J. Sound Vib. 401 (2017) 190-203, https://doi. org/10.1016/j.jsv.2017.04.042.

[138] S. Kumar, T.B. Xiang, H.P. Lee, Ventilated acoustic metamaterial window panels for simultaneous noise shielding and air circulation, Appl. Acoust. 159 (2020) 107088, https://doi.org/10.1016/j.apacoust.2019.107088.

[139] Z. Xiao, P. Gao, D. Wang, X. He, L. Wu, Ventilated metamaterials for broadband sound insulation and tunable transmission at low frequency, Extrem. Mech. Lett. 46 (2021) 101348, https://doi.org/10.1016/j.eml.2021.101348.

[140] J.W. Jung, J.E. Kim, J.W. Lee, Acoustic metamaterial panel for both fluid passage and broadband soundproofing in the audible frequency range, Appl. Phys. Lett. 112 (2018) 41903, https://doi.org/10.1063/1.5004605.