DOI: https://doi.org/10.1007/s11356-024-32468-x

PMID: https://pubmed.ncbi.nlm.nih.gov/38407704

تاريخ النشر: 2024-02-26

مخلفات معاصر الزيتون: من نفايات إلى موارد

© المؤلف(ون) 2024

الملخص

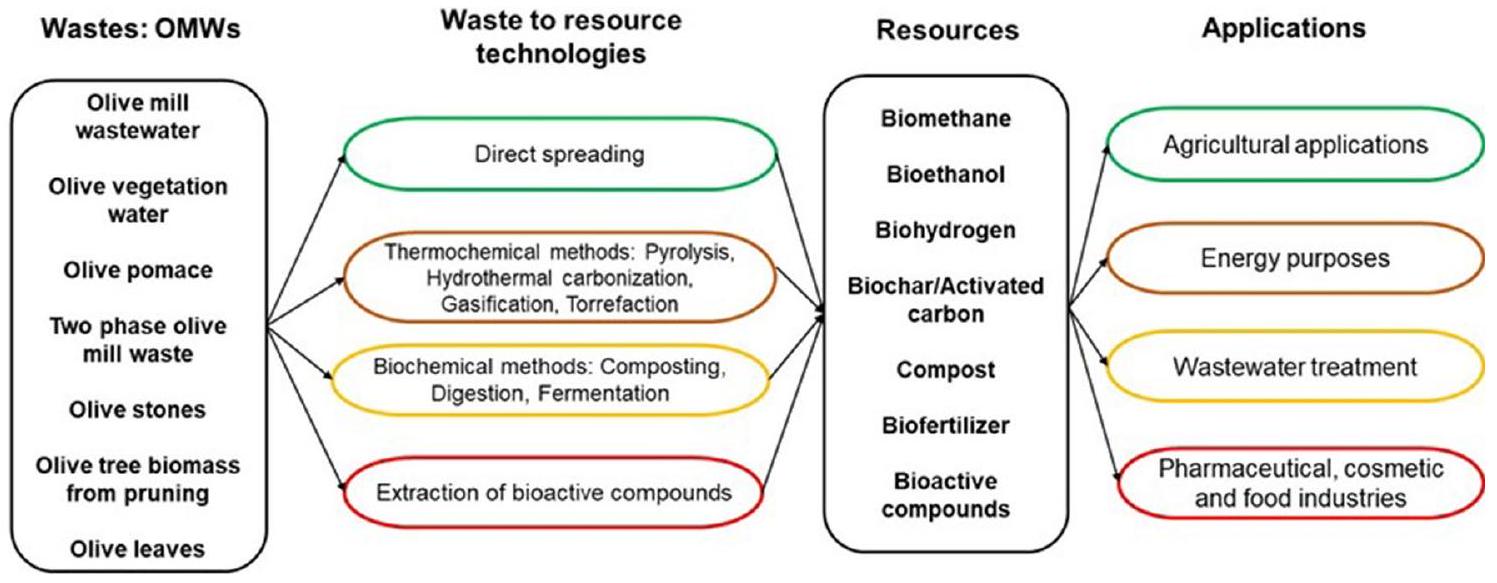

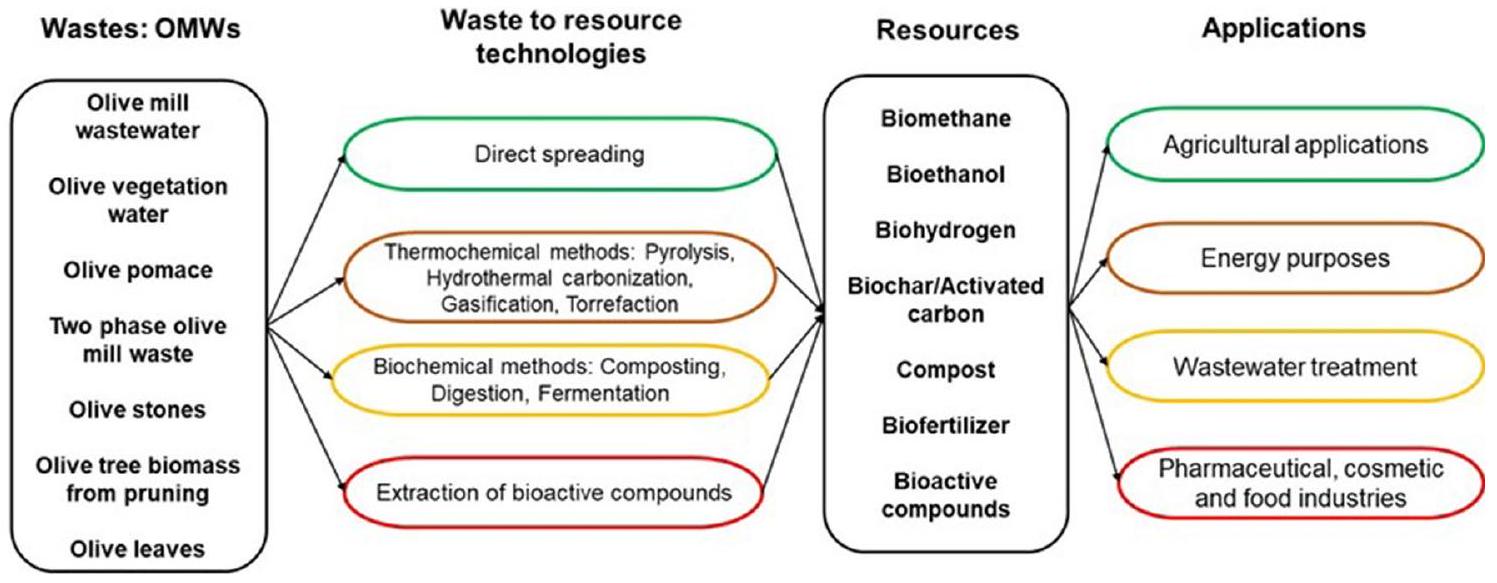

شهد استخراج زيت الزيتون مؤخرًا زيادة مستمرة بسبب خصائصه المفيدة المرتبطة به. وبالتالي، يتم إنتاج كميات كبيرة من نفايات معاصر الزيتون (OMWs) الناتجة عن عملية الطحن سنويًا، مما يسبب مشاكل بيئية خطيرة. تجعل القدرات المالية المحدودة لمعامل الزيتون عادةً غير قادرة على تحمل التكاليف العالية المطلوبة للتخلص من نفاياتها. بدلاً من ذلك، يمكن أن تمثل قيمة نفايات معاصر الزيتون في إطار مفهوم النفايات إلى الموارد وإعادة تدويرها استراتيجية ناجحة لتنفيذ نموذج الاقتصاد الدائري في صناعة الزيتون، مما قد يكون له تأثيرات اجتماعية واقتصادية كبيرة على الدول المتوسطية ذات الدخل المنخفض. ومع ذلك، لا توجد حل فريد لقيمة نفايات معاصر الزيتون، بسبب التنوع الواسع في تركيبة النفايات وإنتاجها الموسمي. في هذه المراجعة، يتم تقييم إمكانيات نفايات معاصر الزيتون لإعادة الاستخدام والتقدم التكنولوجي الأخير في مجال قيمة نفايات معاصر الزيتون. يتم التركيز بشكل خاص على تحليل مزايا وقيود كل تقنية والإبلاغ عن القضايا الأكثر أهمية التي لا تزال تحد من توسيع نطاقها الصناعي. تظهر المعلومات التي تم جمعها في هذه المراجعة أن نفايات معاصر الزيتون يمكن استغلالها بشكل فعال في عدة قطاعات، بما في ذلك إنتاج الطاقة والزراعة. ومع ذلك، يبدو أن إمكانيات نفايات معاصر الزيتون غير مقدرة بشكل كاف، ولا يزال تنفيذ استراتيجيات القيمة المستدامة على نطاق واسع يمثل تحديًا. لا تزال هناك حاجة إلى مزيد من الجهود والإجراءات السياسية، من خلال الإجراءات الجماعية، وتشجيع الدعم، وإقامة تعاونات بين القطاعين العام والخاص، للتوفيق بين تقدم البحث والممارسات الصناعية وتشجيع التنفيذ على نطاق واسع لمفهوم النفايات إلى الموارد في قطاع الزيتون.

المقدمة

السماد الحيوي وتعديلات التربة (ميسينيو وآخرون 2020؛ أودين وآخرون 2021). يمكن أيضًا إعادة استخدام نفايات معاصر الزيتون كوسيلة لنمو الطحالب (هودايفا وآخرون 2013ب)، كمضافات مدمجة في مواد البناء (هيتيريس وآخرون 2004)، ولإنتاج مواد بوليمرية حيوية (نتايكو وآخرون 2009). على الرغم من النتائج الواعدة التي تم الحصول عليها بشأن قيمة نفايات معاصر الزيتون وتحويلها إلى موارد قيمة، لا يزال التطبيق على نطاق واسع للطرق المقترحة محدودًا للعديد من الاعتبارات الفنية والاقتصادية. تلخص هذه المساهمة التحقيقات البحثية الرئيسية التي تتناول قيمة نفايات معاصر الزيتون واستخدامها كموارد بدلاً من معالجتها كنفايات. كانت الأسئلة المحددة كما يلي: ما هي المحركات والخصائص المحتملة لتنفيذ مفهوم النفايات إلى الموارد في قطاع الزيتون؟ ما هو المعرفة الحالية المتعلقة بهذه القضية؟ ما هي القيود الرئيسية التي تعيق التبني الواسع لهذه الاستراتيجية الواعدة وما هي الآفاق المستقبلية؟

تقنيات استخدام نفايات معاصر الزيتون

المياه العميقة كمصدر للطاقة

طرق حرارية كيميائية

تمت ملاحظته أيضًا بسبب المحتوى العالي من OMSW في المادة المتطايرة. قارن توبال وآخرون (2003) كفاءة احتراق كعكة الزيتون والفحم اللجنيتي المعالج بشكل منفصل واحتراقهما المشترك في سرير مائع دائري. أظهرت النتائج أن CO و

| منتج ثانوي | طريقة التقييم | المورد المنتج | تطبيق | النتائج الرئيسية | مرجع | ||||

| بقايا الزيتون | استخراج بالمذيب | زيت البذور | صناعة المواد الغذائية | السماح بالطهي عند درجات حرارة عالية | دونر وآخرون (2022) | ||||

| بقايا الزيتون | – | دقيق وجزيئات دقيقة من بقايا الزيتون | إضافة إلى الأفلام المعتمدة على الكيتوزان |

|

دي مورايس كريزيل وآخرون (2018) | ||||

| بقايا الزيتون | – | – | تحصين المعكرونة بمخلفات الزيتون |

|

سيموناتو وآخرون (2019) | ||||

| بقايا الزيتون | – | – | امتصاص صبغة النسيج من المحلول المائي | تمت إزالة أكثر من 80% من صبغة النسيج | أكار وآخرون (2009) | ||||

| أومس | الهضم اللاهوائي المشترك لنفايات الطعام العضوية مع الطحالب الدقيقة (D. Salina) | – | إنتاج الغاز الحيوي | أقصى كمية من الميثان (330 مل)

|

فرناندز-رودريغيز وآخرون (2014، 2021) | ||||

| TPOMW | الهضم المشترك لمخلفات الزيتون المعالجة بالصودا الكاوية مع نفايات الطعام | – | إنتاج الغاز الحيوي | ال

|

الملاحي وآخرون (2016) | ||||

| حبات الزيتون | طحن التجفيف | دقيق نوى الزيتون | حشوة تعزيز المواد البلاستيكية | تحسين في قوة الانحناء وخصائص حاجز الماء | نغموتشي وآخرون (2015) | ||||

| أوراق الزيتون | استخراج السائل-السائل | مستخلصات مضادات الأكسدة الطبيعية | إضافة إلى زيت عباد الشمس وزيت الصويا ومزيجهما | زيادة في استقرار الزيوت المدروسة | زهران وآخرون (2015) | ||||

| بقايا الزيتون والمياه العادمة لزيت الزيتون | استخراج الميثانول | المركبات الفينولية | إثراء الزبدة | مقاومة عالية ضد الإجهاد التأكسدي أثناء التخزين | ميقدام وآخرون (2020) |

| منتج ثانوي | طريقة التقييم | المورد المنتج | تطبيق | النتائج الرئيسية | مرجع | ||||

| الكتلة الحيوية المعالجة بمياه الصرف الصحي المعالجة وكتلة الكتلة الحيوية الم impregnated (رقائق الخشب وقطع الخشب) | التجفيف بالتوصيل والتكثيف | ماء مكثف مستعاد | – |

|

دوتورنييه وآخرون (2019) | ||||

| تشذيب شجرة الزيتون | طريقة صب المذيب | فيلم تعبئة قابل للتحلل البيولوجي | بوليمر حيوي لتغليف الطعام |

|

سانشيز-غوتيريز وآخرون (2021) | ||||

| كتلة التقليم | تثمين في مصنعين: مصنع مضادات الأكسدة (استخراج سائل-سائل) ومصنع الإيثانول الحيوي (تحليل السكريات والتخمير) | مضادات الأكسدة الطبيعية والإيثانول | إنتاج الطاقة والمنتجات ذات القيمة المضافة العالية | الإيثانول (

|

روميرو-غارثيا وآخرون (2016) | ||||

| أم و م و م و متعبة أ م س و | تشبع النفايات العضوية الصلبة المستنفدة بمياه الزيتون المستعملة | وقود حيوي صلب | احتراق | زيادة في محتوى الطاقة والتفاعل للسماد العضوي المستنفد بعد إضافة مياه الزيتون المستعملة | جيغيريم وآخرون (2012) | ||||

| أوم و | – | – | عامل ترطيب بديل | لم يُلاحظ أي فرق كبير في الركيزة التي تحتوي على 25% من مياه الزيتون المستعملة مقارنة بمجموعة التحكم | كالميس وآخرون (2008) | ||||

| أومو | دمج التجفيف الشمسي والتسميد | سماد عضوي (57% كربون عضوي،

|

استخدم كسماد عضوي لزراعة نباتات الفلفل | خصوبة مشابهة للأسمدة التجارية NPK | غالييو وآخرون (2018) |

| الجدول 1 (مستمر) | ||||||||

| منتج ثانوي | طريقة التقييم | المورد المنتج | تطبيق | النتائج الرئيسية | مرجع | |||

| أوم و | – | – | مضاف غذائي لتركيبة العلف المخمر للأغنام |

|

ماكري وآخرون (2018) | |||

| أومو | – | المركبات الفينولية | مرشحات الأشعة فوق البنفسجية في واقيات الشمس | الفينولات الزيتونية هي مرشحات للأشعة فوق البنفسجية أكثر نشاطًا في نطاق أوسع من الأشعة فوق البنفسجية B و A. | غالاناكيس وآخرون (2018) | |||

| أوم و | ترشيح الميكروفيلتر باستخدام الأغشية الخزفية | البوليفينولات | مكمل غذائي للخنازير الصغيرة |

|

جيراسوبولوس وآخرون (2015) | |||

| OMWW مختلط مع دبس السكر | التخمر | – | إنتاج الإيثانول | تركيز الإيثانول وقيم الإنتاج اليومية المسجلة عند درجات الحرارة

|

نيكولاو وكوركوتاس (2018) | |||

| أومو | تخمير مياه الزيتون المستعملة بواسطة P. jamilae (بكتيريا موجبة الجرام معزولة من سماد قائم على مياه الزيتون المستعملة) | الإكزوبوليسكاريد (بوليمر) | اهتمام بيولوجي تكنولوجي بسبب تطبيقه المحتمل كمواد حيوية لامتصاص المعادن الثقيلة | كمية ملحوظة من البوليسكاريد خارج الخلية

|

موريّو وآخرون (2007) | |||

| أوم و | تخمير الخميرة | – | إنتاج الإيثانول | أقصى إنتاج للإيثانول

|

مسعدة ومدلل (2008) | |||

| أومو | زراعة سلالة بكتيرية في مياه الزيتون المستعملة | السليلوز البكتيري | – | إثراء وسط OMWW (%100) بمستخلص الخميرة

|

سار وأكباش (2022) | |||

| الجدول 1 (مستمر) | |||||

| منتج ثانوي | طريقة التقييم | المورد المنتج | تطبيق | النتائج الرئيسية | مرجع |

| أومو | – | الأصباغ الطبيعية لصناعة النسيج | حمام صبغ لصبغ الصوف | خصائص ثبات اللون الكبيرة لألياف الأكريليك | حدار وآخرون (2014) |

| مياه نبات الزيتون | – | المركبات الفينولية | تحصين مشروبات الحليب (مشابهة لمنتجات الزبادي) | – | سيرفيل وآخرون (2011ب) |

| VS المواد الصلبة المتطايرة | |||||

طرق حيوية كيميائية

(2019)، الذي تضمن ترشيح مياه الزيتون المستعملة على حجارة الزيتون تلاه عملية التجلط والتخثر كخطوة معالجة أولية ثانية. أسفر هذا العملية المجمعة عن تقليل المواد الصلبة المعلقة والدهون بحوالي

عند خلطه مع مصل اللبن. من المثير للاهتمام هو الهضم المشترك لـ OMWW مع OMSW حيث أن كلا الجريان يمثلان قضية إشكالية لمشغلي مطاحن الزيتون و OMSW هو ركيزة غنية بالنيتروجين (

تم إجراء دراسة بواسطة نجفي وآخرون (2021) حيث تم تنفيذ عملية متكاملة تجمع بين التخمر، والهضم اللاهوائي لبقايا التخمر، وإنتاج اللجنين. في نفس الدراسة، تم اختبار ثلاث طرق معالجة مسبقة مختلفة، وهي الماء الساخن السائل، والمذيبات العضوية، والمذيبات العضوية المحفزة بالحمض. باستخدام هذه العملية المجمعة، أفاد المؤلفون بإنتاج 295.5 لتر من الإيثانول الحيوي،

OMWW المركزة للغاية. تم أيضًا التحقيق في الإنتاج المتزامن للإيثانول والهيدروجين الحيوي من مزيج OMWW-بقايا الزيتون باستخدام تخمر لاهوائي بواسطة Saccharomyces cerevisiae من قبل باتيستا وآخرون (2016). درس المؤلفون عدة طرق معالجة مسبقة (المعالجة فوق الصوتية، والمعالجة القلوية، وإضافة كربونات الكالسيوم) لتحسين إطلاق الجلوكوز ثم تعزيز إنتاج الإيثانول والهيدروجين الحيوي وتقليل التأثير المثبط للبوليفينولات على عملية التخمر في الوقت نفسه. أظهرت النتائج أن جميع طرق المعالجة المسبقة حسنت عوائد إنتاج الإيثانول والهيدروجين الحيوي، حيث أدت المعالجات القلوية والفوق صوتية إلى أعلى تركيز من الإيثانول والهيدروجين الحيوي، بسبب مساهمتها في تحسين التحلل المائي للجنين والسليلوز وزيادة محتوى السكريات القابلة للذوبان (لا سيما الجلوكوز) في خليط التفاعل.

تطبيق مياه الزيتون في الزراعة

نشر مياه الزيتون مباشرة في التربة

قد تم الإبلاغ عنه أنه انخفض بشكل كبير بعد بضعة أشهر، بسبب إنتاج الأمونيا الناتج عن التحلل البكتيري للمواد العضوية في مياه الزيتون وقدرة التربة على التخفيف (Regni et al. 2017). إن تأثير نشر مياه الزيتون على ميكروبيولوجيا التربة لا يعود فقط إلى التغير في درجة حموضة التربة، ولكن أيضًا إلى مساهمة المواد العضوية في مياه الزيتون، التي تحفز زيادة في الميكروفلورا في التربة. أفاد Mekki et al. (2006a) بزيادة كبيرة في الأكتينوميسيتات في التربة، والبكتيريا المكونة للجراثيم والفطريات في التربة وانخفاض كبير في عدد بكتيريا النترتة في التربة. وبالمثل، لاحظ Mechri et al. (2007) زيادة في الفطريات في التربة، والبكتيريا سالبة الجرام والأكتينوميسيتات بعد إضافة أكثر من

يمكن استخدامها لأغراض زراعية (Toscano وMontemurro 2012). بخلاف كونها طريقة إدارة اقتصادية وسهلة التطبيق لمشغل مطحنة الزيتون، تم الإبلاغ عن أنها تمنح فوائد كبيرة لخصائص التربة وإنتاجية المحاصيل. أظهر Kavdir وKilli (2007) أن تعديل التربة ببقايا الزيتون يحسن قدرتها على الاحتفاظ بالمياه، والهيكل، والاستقرار، مما يجعلها أقل عرضة للتآكل. يزيد دمج بقايا الزيتون في التربة من محتواها من المواد العضوية ويعزز نشاطها البيولوجي، دون آثار سلبية ملحوظة على قيمة درجة الحموضة والملوحة (Regni et al. 2017؛ Innangi et al. 2017). يعتمد تأثير تطبيق بقايا الزيتون على المواد العضوية في التربة بشكل كبير على طريقة التطبيق. قام Nasini et al. (2013) بنشر كميات كبيرة من بقايا الزيتون (

على محتوى الزيت. التأثير الإيجابي لنشر مياه الزيتون على التربة والمحاصيل مشروط بالاحترام للحد الأقصى للحمولة المسموح بها وتقنية ووقت النشر الصحيح. أفاد لوبيز-بينيرو وآخرون (2007) أن فترة النشر المثلى تتوافق مع الفترة التي تسبق استئناف النمو الخضري. يمكن أن تكون الحمولة المسموح بها أعلى عندما يتم تطبيق مياه الزيتون على المحاصيل الشجرية مثل شجرة الزيتون. بالإضافة إلى ذلك، فإن طبيعة مياه الزيتون تعتبر أيضًا عاملاً مهمًا في تحديد الحمولة المسموح بها. في إيطاليا، يُسمح بالاستخدام الزراعي لمياه الزيتون الناتجة عن أنظمة الاستخراج التقليدية حتى

تسميد OMWs

تطبيق الفحم الحيوي/الهيدروكربوني المستخرج من مياه الصرف الصحي كتحسين للتربة

كبديل لتقدير قيمتها. يمكن أن يحقق التحلل الحراري للمخلفات الزراعية وتحويلها إلى فحم حيوي الهدف من إغلاق الحلقة في الزراعة وأهداف الاقتصاد الدائري في الدول المتوسطية. يمكن استخدام الفحوم الحيوية التي يتم إنتاجها عادةً عن طريق التحلل الحراري البطيء لزيادة درجة حموضة التربة، والموصلية الكهربائية، والفوسفور المتاح، وسعة تبادل الكاتيونات (Biederman وHarpole 2012؛ Marks وآخرون 2016). يمكن أن تجعل الخصائص القلوية للفحم الحيوي، وتركيزها المرتفع من الكالسيوم والمغنيسيوم، وسعة الامتصاص الخاصة بها مفيدة لاستراتيجيات الترميم، مثل احتجاز المعادن (Alburquerque وآخرون 2014). أظهرت تطبيقات الفحم الحيوي المستمد من مياه الزيتون تأثيرات إيجابية على نمو النباتات من خلال تعزيز تكاثر الجذور الدقيقة وتسهيل احتباس الماء والمواد الغذائية (Olmo وآخرون 2014؛ Marks وآخرون 2020). يعتبر تحويل مياه الزيتون إلى فحم حيوي استراتيجية جيدة لاحتجاز الكربون، نظرًا لتركيزها العالي من الكربون المقاوم الذي يظهر معدلات تحلل منخفضة وأوقات إقامة طويلة للتدهور؛ وتكون هذه القدرة أكثر وضوحًا بالنسبة للفحوم الحيوية المستمدة من الزيتون (Alburquerque وآخرون 2014؛ Olmo وآخرون 2014). ومع ذلك، فإن الفحوم الحيوية المستمدة من مياه الزيتون، مثل معظم المواد الخام اللجنوسليلوزية، تظهر محتويات منخفضة من النيتروجين (الجدول 2)، مما قد يحد من كفاءتها كسماد (Marks وآخرون 2020). قام حداد وآخرون (2017) بعملية نقع نشارة الخشب بمياه الزيتون لاستعادة محتواها من العناصر الغذائية، تلاها التجفيف والتحلل الحراري البطيء. في الواقع، تزيد هذه الاستراتيجية من محتوى النيتروجين في الفحم الحيوي النهائي بالإضافة إلى إثرائه بالعناصر الغذائية الكبرى والصغرى. تعتبر الفحوم الحيوية المستمدة من مياه الزيتون أيضًا مواد كربونية قيمة في الزراعة بسبب تحلل الكربون البطيء ومحتوياتها المعدنية العالية (Kambo وDutta 2015). على الرغم من أن الفحم الحيوي والفحم الهيدرو يمكن استخدامهما في الزراعة لأغراض مشابهة لتحسين الخصائص الهيكلية والفيزيائية والكيميائية والميكروبيولوجية للتربة، إلا أن خصائصهما الفيزيائية والكيميائية مختلفة (الجدول 2)، لأن التفاعلات المعنية خلال العملية الحرارية المستخدمة في إنتاجهما مختلفة (Enaime وآخرون 2023). يظهر الفحم الهيدرو عمومًا درجة حموضة منخفضة مقارنة بالفحم الحيوي المستمد من مياه الزيتون (الجدول 2)، بسبب

| معامل | في الطريق | سماد عضوي | الكتلة الحيوية | هيدروشار |

| درجة الحموضة | ٤.٢-٦.٨ | 7.4-9.5 | 7.7-11.0 | 5.29 |

| EC [دس/m] | 0.98-12.0 | 1.6-7.3 | 0.28-2.15 | 0.29 |

| TN [غ/كغ] | 0.61-18.5 | 11-54.0 | 4.1-13.0 | 1.91 |

| رقم التعريف | ٢٨.٢-٧٢.٩ | 9-36.0 | ٢٦.١٧-٢٢٧ | ٢٩.٥٢ |

| إجمالي الفوسفور [غ/كغ] | 0.06-2.2 | 0.2-30.0 | 0.14-8.34 | 0.04 |

| إجمالي K [غ/كغ] | 1.97-29.7 | 2.3-44 | 6.3-30.0 | 1.98 |

| فهرس [

|

٣٤.٢-٥٣٩.٠ | ٣٨٢-٥٨٠ | ٤٨٣-٩٣٣ | – |

| الفينولات [%] | 0.5-10.7 | 0.1-3.8 | – | – |

تطبيق مياه الزيتون كمبيد حيوي

تم أيضًا إظهار تثبيط الفقس بواسطة سماد TPOMW، والذي يُفترض أنه بسبب وجود مركبات حيوية نشطة قادرة على المرور عبر قشرة بيض النيماتود. يمكن أن يؤدي استخدام السماد المستخرج من OMW كإضافة للتربة أيضًا إلى ممارسة تأثير بيوبستيدي ضد مسببات الأمراض النباتية بسبب محتواها العالي من العناصر الغذائية والمركبات القاتلة (التانينات والمركبات الفينولية)، والتي تحفز تطوير الجذور وتعزز نمو النبات (ساسانيلي وآخرون 2011). اقترح أوكا وييرميهيو (2002) أن قدرة السماد على تثبيط النيماتود قد تكون بسبب تركيزاتها العالية

تغذية الماشية باستخدام OMWs

نشاطهم المضاد للأكسدة. تم مراقبة 24 دجاجة لاحم تتلقى أعلاف مكملة بـ OMWW لمدة 37 يومًا، وتم جمع عينات من الدم والأنسجة (العضلات، القلب، الكبد) في فترات مختلفة. لوحظت قدرة إجمالية أعلى لمضادات الأكسدة في البلازما والأنسجة للدجاج اللاحم الذي يتلقى أعلاف مكملة بـ OMWW مع انخفاض كبير في أكسدة البروتين ومستويات أكسدة الدهون مقارنةً بالتحكم. حتى مع الفوائد الموثقة جيدًا لإضافة OMWs في أعلاف الحيوانات، هناك بعض الحواجز التي تحد من استخدامها الأوسع، بما في ذلك محتواها المنخفض من البروتين وتأثيرها العكسي بسبب محتواها العالي من الطاقة، مما يمكن أن يقلل من إجمالي استهلاك الحيوانات من العلف. من الضروري احترام النسبة المثلى للإضافة (

تطبيق OMWs في معالجة مياه الصرف الصحي

إزالة المعادن الثقيلة من مياه الصرف الصناعي. أفاد تشوشين وآخرون (2014) بكفاءة إزالة Cu وNi بنسبة 3.6 و

تشذيب شجرة الزيتون بالوسائل الفيزيائية

المياه العميقة كمصدر لمكونات حيوية نشطة

الذي يؤثر بشكل كبير على تركيبها. على سبيل المثال، تم الإبلاغ عن تراكم الهيدروكسيتييروسول وتقليل المركبات الفينولية الأخرى الأحادية والمتعددة كأثر لتخزين مياه الزيتون المستعملة لفترة طويلة (فيكي وآخرون 2006).

(دي ليونارديس وآخرون 2007؛ سانينو وآخرون 2013). تم استخدام وسائط قطبية بروتينية أخرى مثل الخلطات الهيدروكحولية أيضًا بتركيزات مختلفة لاستخراج الأحماض الفينولية. قد تكون التطبيقات الصناعية للمركبات النشطة بيولوجيًا المستردة بواسطة طريقة الاستخراج السائلة محدودة بسبب سمية وعدم صلاحية بعض المذيبات، مما يثير مخاوف بيئية وصحية وسلامة (غالاناكيس وكوتسيو 2017). بدلاً من ذلك، يمكن استرداد المركبات النشطة بيولوجيًا بواسطة أنظمة ترشيح الأغشية بما في ذلك الترشيح الدقيق، والترشيح الفائق، والترشيح النانوي، والتناضح العكسي. قام سيرفيلي وآخرون (2011a) باسترداد الفينولات المحبة للماء من مياه الزيتون النباتية الطازجة في مصنع صناعي باستخدام نظام غشاء ثلاثي المراحل (الترشيح الدقيق، والترشيح الفائق، والتناضح العكسي) قبل المعالجة الإنزيمية. أسفر هذا النهج عن تركيز غني بالمركبات الفينولية تم استخدامه بشكل فعال لزيادة محتوى مضادات الأكسدة في زيت الزيتون البكر. تم استخدام فلاتر طبيعية مثل فلاتر النشا المستخرجة من الفواكه والحبوب والدرنات أيضًا من قبل فرنانديز-غوتيريز وآخرون (2013) في عملية مسجلة لاستخراج المركبات النشطة بيولوجيًا من المنتجات الثانوية لزيت الزيتون. تم أيضًا فصل المركبات الفينولية من مياه الزيتون المستعملة باستخدام مواد ماصة مختلفة مثل الكربون النشط والراتنجات. على سبيل المثال، قام يانغوي وعبد الرابا (2018) باستخراج الفينولات الكلية (

| المركبات | المنتج الثانوي الناتج | التركيز النسبي | طريقة الاستخراج | المرجع |

| المركبات الفينولية | مياه الزيتون المستعملة |

|

استخراج سائل-سائل ودمج عملية فينتون | نونزيو وآخرون (2018) |

| مياه الزيتون النباتية |

|

استخراج ترشيح الأغشية سائل/سائل | مارتينز وآخرون (2021) | |

| مخلفات الزيتون |

|

استخراج بالماء | هناشي وآخرون (2020) | |

| حجارة الزيتون |

|

عملية النقع باستخدام الميثانول كمذيب للاستخراج | سيرفيلي وآخرون (2011a) | |

| أوراق الزيتون | 211.385 ملغ معادل حمض التانيك/غ | استخراج الميثانول | رحماني وآخرون (2015) | |

| الهيدروكسيتييروسول | حجارة الزيتون |

|

استخراج صلب-سائل باستخدام (الميثانول، الإيثانول، والأسيتون) كمذيب | ناكيلسيوغلو-تاش وأوتليش (2019) |

| أوراق الزيتون | 0.53-1.12% من ورق الزيتون الجاف | استخراج الإيثانول | غويندا وآخرون (2015) | |

| مياه الزيتون المستعملة |

|

معالجة البكتيناز وترشيح الأغشية | ترويز وآخرون (2014) | |

| أومو |

|

|

بينيكاسا وآخرون (2019) | |

| كتلة حيوية من شجرة الزيتون الناتجة عن التقليم |

|

استخراج السوائل فوق الحرجة | بينيكاسا وآخرون (2019) | |

| بقايا الزيتون |

|

|

كاباليرو وآخرون (2020) | |

| ألبيروجو |

|

استخراج بمساعدة الموجات فوق الصوتية والمذيبات الطبيعية العميقة المتجانسة | بلازا وآخرون (2020) | |

| تايروسول | بقايا الزيتون |

|

معالجة البكتيناز وترشيح الأغشية | ترويز وآخرون (2014) |

| أوم و |

|

استخراج السائل-السائل ودمج عملية فينتون | مارتينز وآخرون (2021) | |

| أومو |

|

استخراج الميثانول | برونو وآخرون (2021) | |

| حبات الزيتون |

|

استخراج الميثانول: الماء | رايان وآخرون (2003) | |

| كيكة الزيتون من عملية ذات مرحلتين (الأرجنتين) |

|

الاستخراج بمساعدة الموجات فوق الصوتية والمذيبات العميقة الطبيعية | بلازا وآخرون (2020) | |

| أوليوروبين | أومو |

|

استخراج الميثانول | برونو وآخرون (2021) |

| بقايا |

|

استخراج الميثانول | برونو وآخرون (2021) | |

| أوراق الزيتون |

|

استخراج السائل فوق الحرج / استخراج سوكليت | بلازا وآخرون (2020) | |

| بقايا الزيتون |

|

استخراج السائل فوق الحرج / استخراج سوكليت | بلازا وآخرون (2020) | |

| حجر الزيتون |

|

استخراج الصلب-السائل باستخدام الميثانول والإيثانول والأسيتون كمذيب | ناكيلجيوغلو-تاش وأوتليس (2019) | |

| حمض السيرينجيك | حبات الزيتون |

|

استخراج الصلب-السائل باستخدام الميثانول والإيثانول والأسيتون كمذيب | ناكيلجيوغلو-تاش وأوتليس (2019) |

| المركبات | منتج ثانوي منشأ | التركيز النسبي | طريقة الاستخراج | مرجع |

| حمض p-كوماريك | أومو |

|

استخراج السائل-السائل ودمج عملية فينتون | مارتينز وآخرون (2021) |

| أومس |

|

المعالجة الحرارية المسبقة عند درجات حرارة عالية واستعادة الفينول باستخدام نظام كروماتوغرافي صناعي | سيرانو وآخرون (2017) | |

| حمض السيرينجيك | أوم و |

|

استخراج السائل-السائل ودمج عملية فينتون | مارتينز وآخرون (2021) |

| حمض الفانيليك | بقايا |

|

استخراج الميثانول | برونو وآخرون (2021) |

| كتلة حيوية من شجرة الزيتون الناتجة عن التقليم | 2.10 ملغ كغ | استخراج الميثانول | برونو وآخرون (2021) | |

| أوراق الزيتون |

|

استخراج السوائل فوق الحرجة | كاباليرو وآخرون (2020) | |

| فانيلا | أوم و |

|

استخراج الميثانول | برونو وآخرون (2021) |

| بقايا |

|

استخراج الميثانول | برونو وآخرون (2021) | |

| كتلة حيوية من شجرة الزيتون الناتجة عن التقليم |

|

استخراج السوائل فوق الحرجة | كاباليرو وآخرون (2020) | |

| لوتيوين-7-O-غلوكوزيد | أومو |

|

استخراج الميثانول | برونو وآخرون (2021) |

| بقايا |

|

استخراج الميثانول | برونو وآخرون (2021) |

استعادة فقط

تطبيقات أخرى لمياه الزيتون

2021). تم الإبلاغ عن عدة مزايا بعد دمج بقايا الزيتون كمكون في تصنيع السيراميك مقارنة بالمنتجات السيراميكية التقليدية، بما في ذلك كثافة أقل بنسبة 10% وموصلية حرارية أقل بنسبة 18%، بالإضافة إلى توفير الطاقة بسبب محتواها من المواد العضوية (رويذ وآخرون 2017). تم دراسة تطبيقات أخرى لبقايا الزيتون أيضًا. التركيز العالي لبقايا الزيتون في المعادن والأحماض الدهنية والمركبات النشطة بيولوجيًا، التي تتميز بخصائصها المرطبة ومضادة الشيخوخة، يعزز تطبيقها في علاج السبا (رودريغز وآخرون 2017). يمكن أيضًا استخدام بقايا الزيتون كوسيط نمو سائل للميكروبات الليبوليتيك بسبب محتواها من الزيت المتبقي الذي يختلف حسب عملية استخراج زيت الزيتون (أسس وآخرون 2009). صناعة الأصباغ هي مجال آخر لتطبيق بقايا الزيتون. يمكن أن تكون بقايا الزيتون، التي تتميز بلونها النموذجي، مصدرًا قيمًا للأصباغ الطبيعية، والتي يمكن أن تكون بديلاً للأصباغ الاصطناعية. تم إجراء بعض الدراسات البحثية لتحديد الظروف المثلى لاستخراج الأصباغ من بقايا الزيتون مع نتائج واعدة، بينما درست دراسات أخرى قابلية استخدام الأصباغ المشتقة من بقايا الزيتون في صناعة النسيج (مكسي وآخرون 2012).

المشاكل المتعلقة بإدارة بقايا الزيتون والحواجز أمام إمكانية تنفيذ الحل المقترح

القطاع الزراعي، كمادة ماصة لمعالجة مياه الصرف، أو كمصدر جذاب للمركبات النشطة بيولوجيًا.

أكثر جاذبية. بينما يعتبر إضافة بقايا الزيتون إلى بقايا الزيتون غير منتجة من وجهة نظر تحويل الطاقة للعمليات الحرارية الجافة، فإنها مفيدة لعمليات HTC. عند مقارنة توفير الطاقة لعمليات HTC والانحلال الحراري خلال المعالجة الحرارية لبقايا الزيتون ذات محتوى رطوبة أعلى، يبدو أن HTC يمكن أن تكون طريقة واعدة لتحويل بقايا الزيتون إلى وقود حيوي، مع توفير طاقة يبلغ حوالي

- تصنيف صناعات استخراج زيت الزيتون وفقًا لحجمها وقدرتها على إنتاج النفايات من أجل تنفيذ تدابير محددة لإدارة

| طريقة التثمين | المزايا | القيود | |||||||||||

| توليد الطاقة |

|

|

|||||||||||

| تطبيقات الزراعة |

|

|

|||||||||||

| استخراج المركبات الحيوية النشطة |

|

|

|||||||||||

| تطبيقات البناء |

|

-متطلبات التكلفة لجمع ونقل مياه الزيتون من المعاصر أو المزارع نحو مرافق الاستخدام |

- إجراء مقابلات مع مختلف أصحاب المصلحة وزيارات ميدانية من أجل تحليل جميع العوامل السياسية والقانونية والاقتصادية والاجتماعية والجغرافية والتقنية وإنشاء قاعدة بيانات تصف الحاجة المحددة لكل منطقة.

- دعم البحث العلمي والتطوير، الذي يمكن أن يوفر الأسس الأساسية للابتكار التكنولوجي في مجال تثمين مياه الزيتون مما يسمح بتحقيق نتائج مرضية.

- تطوير شبكة بين العلماء لتسهيل التواصل وتعزيز التعاون بينهم، مما قد يتجنب إهدار الوقت والموارد والخبرات.

- إنشاء سياسات محددة لمساعدة منتجي زيت الزيتون والتعاونيات على اعتماد ممارسات إدارة النفايات المستدامة؛ على سبيل المثال، تعزيز الحوار مع العلماء، سيسمح ذلك بربط العديد من أصحاب المصلحة بمشاريع البحث والمشاريع الريادية المخصصة لتثمين مياه الزيتون.

- الدعم الحكومي لاستراتيجية تحويل النفايات إلى موارد في قطاع الزيتون من خلال حوافز الاستثمار والشراكات المستدامة بين القطاعين العام والخاص.

الخاتمة وآفاق المستقبل

القطاع الصناعي، بما في ذلك وحدات استخراج زيت الزيتون الصغيرة، وصانعي السياسات، ووحدات البحث العلمي، وزيادة وعي المستهلكين بمفهوم تحويل النفايات إلى موارد وفوائدها البيئية والاجتماعية والاقتصادية، وتعزيز دعم الدولة من خلال حوافز الاستثمار والشراكات المستدامة بين القطاعين العام والخاص.

الإعلانات

موافقة الأخلاقيات غير قابلة للتطبيق.

موافقة النشر غير قابلة للتطبيق.

الوصول المفتوح هذه المقالة مرخصة بموجب رخصة المشاع الإبداعي للاستخدام والمشاركة والتكيف والتوزيع وإعادة الإنتاج في أي وسيلة أو شكل، طالما أنك تعطي الائتمان المناسب للمؤلفين الأصليين والمصدر، وتوفر رابطًا لرخصة المشاع الإبداعي، وتوضح ما إذا كانت هناك تغييرات قد أُجريت. الصور أو المواد الأخرى من طرف ثالث في هذه المقالة مشمولة في رخصة المشاع الإبداعي للمقالة، ما لم يُذكر خلاف ذلك في سطر ائتمان للمادة. إذا لم تكن المادة مشمولة في رخصة المشاع الإبداعي للمقالة واستخدامك المقصود غير مسموح به بموجب اللوائح القانونية أو يتجاوز الاستخدام المسموح به، ستحتاج إلى الحصول على إذن مباشرة من صاحب حقوق الطبع والنشر. لعرض نسخة من هذه الرخصة، قم بزيارةhttp://creativecommons.org/licenses/by/4.0/.

References

Abdelhadi S, Dosoretz C, Rytwo G, Gerchman Y, Azaizeh H (2017) Production of biochar from olive mill solid waste for heavy metal removal. Bioresour Technol 244:759-767

Abid N, Masmoudi M, Megdiche M, Barakat A, Ellouze M, Chamkha M, Ksibi M, Sayadi S (2022) Biochar from olive mill solid waste as an eco-friendly adsorbent for the removal of polyphenols from olive mill wastewater. Chem Eng Res Des 181:384-398

Afsari M, Mohebbifar A, Torki M (2014) Effects of dietary inclusion of olive pulp supplemented with probiotics on productive performance, egg quality and blood parameters of laying hens. Annu Res Rev Biol 4:198-211

Aguilar-Reynosa A, Romaní A, Rodríguez-Jasso R, Aguilar C, Garrote G, Ruiz H (2017) Microwave heating processing as alternative of pretreatment in second-generation biorefinery: an overview. Energ Convers Manag 136:50-65

Akar T, Tosun I, Kaynak Z, Ozkara E, Yeni O, Sahin EN, Akar ST (2009) An attractive agro-industrial by-product in environmental cleanup: dye biosorption potential of untreated olive pomace. J Hazard Mater 166:1217-1225

Albadarin A, Mangwandi C (2015) Mechanisms of alizarin red s and methylene blue biosorption onto olive stone by-product: isotherm study in single and binary systems. J Environ Manag 164:86-93

Alburquerque J, Gonzálvez J, García D, Cegarra J (2006) Composting of a solid olive mill by-product and the potential of the resulting compost for cultivating pepper under commercial conditions. Waste Manag 6:620-626

Alburquerque J, Calero J, Barrón V, Torrent J, del Campillo M, Gallardo A, Villar R (2014) Effects of biochars produced from different feedstocks on soil properties and sunflower growth. J Plant Nutr Soil Sci 177:16-25

Aliotta G, Fiorentino A, Oliva A, Temussi F (2002) Olive oil mill wastewater: isolation of polyphenols and their phytotoxicity in vitro. Allelopath J 9:9-17

Allaoui S, Bennani M, Ziyat H, Qabaqous O, Tijani N, Ittobane N, Hodaifa G (2021) Valorization of crude olive stone in the

removing of polyphenols from crude olive mill wastewater: kinetic, isotherm and mechanism study. Heliyon 7:e075252

Al-Mallahi J, Furuichi T, Ishii K (2016) Appropriate conditions for applying NaOH -pretreated two-phase olive milling waste for codigestion with food waste to enhance biogas production. Waste Manag 48:430-439

Anastopoulos I, Massas I, Ehaliotis C (2015) Use of residues and byproducts of the olive oil production chain for the removal of pollutants from environmental media: a review of batch biosorption approaches. J Environ Sci Health, Part A 50:677-718

Annab H, Fiol N, Villaescusa I, Essamri A (2019) A proposal for the sustainable treatment and valorisation of olive mill wastes. J Environ Chem Eng 7:102803

Armesto L, Bahillo A, Cabanillas A, Veijonen K, Otero J, Plumed A, Salvador L (2003) Co-combustion of coal and olive industry residues in fluidized bed. Fuel 82:993-1000

Asses N, Ayed L, Bouallagui H, Ben Rejeb I, Gargouri M, Hamdi M (2009) Use of Geotrichum candidum for olive mill wastewater treatment in submerged and static culture. Bioresour Technol 100:2182-2188

Atimtay A, Topal H (2004) Co-combustion of olive cake with lignite coal in a circulating fluidized bed. Fuel 83:859-867

Azbar N, Keskin T, Yuruyen A (2008) Enhancement of biogas production from olive mill effluent (OME) by co-digestion. Biomass Bioenergy 32:1195-1201

Azzaz A, Jeguirim M, Kinigopoulou V, Doulgeris C, Goddard ML, Jellali S, Ghimbeu CM (2020) Olive mill wastewater: from a pollutant to green fuels, agricultural and water source and bio-fertilizer-hydrothermal carbonization. Sci Total Environ 733:139314

Baccar R, Bouzid J, Feki M, Montiel A (2009) Preparation of activated carbon from Tunisian olive-waste cakes and its application for adsorption of heavy metal ions. J Hazard Mater 162:1522-1529

Banat F, Al-Asheh S, Al-Ahmad R, Bni-Khalid F (2007) Bench-scale and packed bed sorption of methylene blue using treated olive pomace and charcoal. Biores Technol 98:3017-3025

Barba F, Brianceau S, Turk M, Boussetta N, Vorobiev E (2015) Effect of alternative physical treatments (ultrasounds, pulsed electric fields, and high-voltage electrical discharges) on selective recovery of bio-compounds from fermented grape pomace. Food Bioproc Tech 8:1139-1148

Battista F, Mancini G, Ruggeri B, Fino D (2016) Selection of the best pretreatment for hydrogen and bioethanol production from olive oil waste products. Renew Energy 88:401-407

Benavente V, Fullana A (2015) Torrefaction of olive mill waste. Biomass Bioenerg 73:186-194

Benavente V, Fullana A, Berge N (2017) Life cycle analysis of hydrothermal carbonization of olive mill waste: comparison with current management approaches. J Clean Prod 142:2637-2648

Benincasa C, Torre CL, Plastina P, Fazio A, Perri E, Caroleo MC, Gallelli L, Cannataro R, Cione E (2019) Hydroxytyrosyl oleate: improved extraction procedure from olive oil and by-products, and in vitro antioxidant and skin regenerative properties. Antioxidants 233:8

Berbel J, Posadillo A (2018) Review and analysis of alternatives for the valorisation of agro-industrial olive oil by-products. Sustainability 10:237

Berrios M, Angeles M, Martın M (2012) Treatment of pollutants in wastewater: adsorption of methylene blue onto olive-based activated carbon. J Ind Eng Chem 18:780-784

Biederman L, Harpole W (2012) Biochar and its effects on plant productivity and nutrient cycling: a meta-analysis. GCB Bioenergy 5:202-214

Bonari E, Giannini C, Ceccarini L, Silvestri N, Tonini M, Sabbatini T (2001) Spargimento delle acque di vegetazione dei frantoi oleari sul terreno agrario. Inf Agrar 57:8-12

Bouaziz M, Feki I, Ayadi M, Jemai H, Sayadi S (2010) Stability of refined olive oil and olive-pomace oil added by phenolic compounds from olive leaves. Eur J Lipid Sci Technol 112:894-905

Boubaker F, Ridha BC (2007) Anaerobic co-digestion of olive mill wastewater with olive mill solid waste in a tubular digester at mesophilic temperature. Bioresour Technol 98:769-774

Boz O, Dogan M, Albay F (2003) Olive processing wastes for weed control. Weed Res 43:439-443

Boz O, Ogüt D, Kır K, Doğan M (2009) Olive processing waste as a method of weed control for okra, faba bean, and onion. Weed Technol 23:569-573

Brunetti G, Plaza C, Senesi N (2005) Olive pomace amendment in mediterranean conditions: effect on soil and humic acid properties and wheat (Triticum turgidum L.). J Agric Food Chem 53:6730-6737

Bruno AD, Romeo R, Piscopo A, Poiana M (2021) Antioxidant quantification in different portions obtained during olive oil extraction process in an olive oil press mill. J Sci Food Agric 101:1119-1126

Caballero AS, Romero-García JM, Castro E, Cardona CA (2020) Supercritical fluid extraction for enhancing polyphenolic compounds production from olive waste extracts. J Chem Technol Biotechnol 95:356-362

Cayuela M, Bernal M, Roig A (2004) Composting olive mill waste and sheep manure for orchard use. Compost Sci Util 12:130-136

Cayuela M, Millner P, Meyer S, Roig A (2008) Potential of olive mill waste and compost as biobased pesticides against weeds, fungi, and nematodes. Sci Total Environ 399:11-18

Chouchene A, Jeguirim M, Trouvé G (2014) Biosorption performance, combustion behavior, and leaching characteristics of olive solid waste during the removal of copper and nickel from aqueous solutions. Clean Techn Environ Policy 16:979-986

Christoforou E, Fokaides PA (2016) A review of olive mill solid wastes to energy utilization techniques. Waste Manag 49:346-363

da Rosa G, Martiny TR, Dotto GL, Vanga SK, Parrine D, Gariepy Y, Lefsrud M, Raghavan V (2021) Eco-friendly extraction for the recovery of bioactive compounds from Brazilian olive leaves. Sustain Mater Technol 28:e00276

De la Casa J, Lorite M, Jiménez J, Castro E (2009) Valorisation of wastewater from two-phase olive oil extraction in fired clay brick production. J Hazard Mater 169:271-278

De Leonardis A, Macciola V, Lembo G, Aretini A, Nag A (2007) Studies on oxidative stabilisation of lard by natural antioxidants recovered from olive-oil mill wastewater. Food Chem 100:998-1004

De Moraes Crizel T, de Oliveira Rios A, Alves DV, Bandarra N, Moldão-Martins M, Hickmann Flôres S (2018) Active food packaging prepared with chitosan and olive pomace. Food HydroColloids 74:139-150

Delgado-Moreno L, Bazhari S, Gasco G, Méndez A, Azzouzi ME, Romero E (2021) New insights into the efficient removal of emerging contaminants by biochars and hydrochars derived from olive oil wastes. Sci Total Environ 752:141838

Di Giacomo G, Romano P (2022) Evolution of the olive oil industry along the entire production chain and related waste management. Energies 15:465

Di Giovacchino L, Seghetti L (1990) Lo smaltimento delle acque di vegetazione delle olive su terreno agrario destinato alla coltivazione di grano e mais. L’informatore Agrario 4:58-62

Donner M, Radic I (2021) Innovative circular business models in the olive oil sector for sustainable mediterranean agrifood systems. Sustainability 13:2588

Doula MK, Tinivella F, Moreno Ortego LL, Kavvadias VA, Sarris A, Theocharopoulos S, Sanchez-Monedero MA, Elaiopoulos K (2012) Good practices for the agronomic use of olive mill wastes: application guide. PROSODOL Project (IFE07 ENV/ GR/000280). Available online: http://www.prosodol.gr/sites/ prosodol.gr/files/DGr_7.pdf. Accessed on 3 March 2019

Ducom G, Gautier M, Pietraccini M, Tagutchou JP, Lebouil D, Gourdon R (2020) Comparative analyses of three olive mill solid residues from different countries and processes for energy recovery by gasification. Renew Energy 145:180-189

Dutournié P, Jeguirim M, Khiari B, Goddard ML, Jellali S (2019) Olive mill wastewater: from a pollutant to green fuels, agricultural water source, and bio-fertilizer. Part 2: Water recovery. Water 11:768

El-Abbassi A, Saadaoui N, Kiai H, Raiti J, Hafidi A (2017) Potential applications of olive mill wastewater as biopesticide for crops protection. Sci Total Environ 576:10-21

Enaime G, Ennaciri K, Ounas A, Baçaoui A, Seffen M, Selmi T, Yaacoubi A (2017) Preparation and characterization of activated carbons from olive wastes by physical and chemical activation: application to indigo carmine adsorption. J Mater Environ Sci 8:4125-4137

Enaime G, Baçaoui A, Yaacoubi A, Wichern M, Lübken M (2019) Olive mill wastewater pretreatment by combination of filtration on olive stone filters and coagulation-flocculation. Environ Technol 40:2135-2146

Enaime G, Baçaoui A, Yaacoubi A, Belaqziz M, Wichern M, Lübken M (2020a) Phytotoxicity assessment of olive mill wastewater treated by different technologies: effect on seed germination of maize and tomato. Environ Sci Pollut Res 27:8034-8045

Enaime G, Baçaoui A, Yaacoubi A, Lübken M (2020b) Biochar for wastewater treatment-conversion technologies and applications. Appl Sci 10:3492

Enaime G, Baçaoui A, Yaacoubi A, Wichern M, Lübken M (2022) Hydrothermal carbonization of the filter bed remained after filtration of olive mill wastewater on olive stones for biofuel application. Biomass Convers Biorefin 12:1237-1247

Enaime G, Wichern M, Lübken M (2023) Contribution of biochar application to the promotion of circular economy in agriculture. Front Agron 5:1214012

Eroğlu E, Eroğlu İ, Gündüz U, Türker L, Yücel M (2006) Biological hydrogen production from olive mill wastewater with two-stage processes. Int J Hydrog 31:1527-1535

Esteves BM, Morales-Torres S, Madeira LM, Maldonado-Hódar FJ (2022) Specific adsorbents for the treatment of OMW phenolic compounds by activation of bio-residues from the olive oil industry. J Environ Manag 306:114490

Feki M, Allouche N, Bouaziz M, Gargoubi A, Sayadi S (2006) Effect of storage of olive mill wastewaters on hydroxytyrosol concentration. Eur J Lipid Sci Technol 108:1021-1027

Fernandes M, Torrado I, Carvalheiro F, Dores V, Guerra V, Lourenço P, Duarte L (2016) Bioethanol production from extracted olive pomace: dilute acid hydrolysis. Bioethanol 2:103-111

Fernandez-Gutierrez A, Segura-Carretero A, Lozano-Sanchez J (2013) Procedimiento para filtrar aceite usando tortas filtrantes de almidon nativo. Spain Patent ES 2374247:B1

Fernández-Rodríguez M, Rincon B, Fermoso F, Jimenez A, Borja R (2014) Assessment of two-phase olive mill solid waste and microalgae co-digestion to improve methane production and process kinetics. Bioresour Technol 157:263-269

Fernández-Rodríguez MJ, Mancilla-Leytón J, Jiménez-Rodríguez A, Borjaa R, Rincón B (2021) Reuse of the digestate obtained from the biomethanization of olive mill solid waste (OMSW) as soil

amendment or fertilizer for the cultivation of forage grass (lolium rigidum var. wimmera). Sci Total Environ 792:148465

Fokaides P, Polycarpou P (2013) Exploitation of olive solid waste for energy purposes. In: Poullikkas A (ed) Renewable energy, economies, emerging technologies and global practices. Nova Science Publishers Inc., New York, pp 163-178

Fornes F, Belda RM, Lidon A (2015) Analysis of two biochars and one hydrochar from different feedstock: focus set on environmental, nutritional and horticultural considerations. J Clean Prod 86:40-48

Galanakis C (2012) Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci Technol 26:68-87

Galanakis C (2021) Functionality of food components and emerging technologies. Foods 10:1-26

Galanakis C, Tsatalas P, Galanakis I (2018) Phenols from olive mill wastewater and other natural antioxidants as UV filters in sunscreens. Environ Technol Innov 9:160-168

Galanakis CM, Kotsiou K (2017) Recovery of bioactive compounds from olive mill waste. In: Galanakis CM (ed) Olive mill waste: recent advances for the sustainable management. Elsevier-Academic Press, London, pp 205-229

Galliou F, Markaki N, Fountoulakis MS, Nikolaidis N, Manios T (2018) Production of organic fertilizer from olive mill wastewater by combining solar greenhouse drying and composting. Waste Manag 75:305-311

Garcia-Gomez A, Bernal M, Roig A (2002) Growth of ornamental plants in two composts prepared from agroindustrial wastes. Bioresour Technol 83:81-87

Gascó G, Paz-Ferreiro J, Álvarez M, Saa A, Méndez A (2018) Biochars and hydrochars prepared by pyrolysis and hydrothermal carbonisation of pig manure. Waste Manag 79:395-403

Gerasopoulos K, Petrotos K (2022) Utilization of olive mill waste waters to produce bioactive animal feed. In: Membrane engineering in the circular economy: renewable sources valorization in energy and downstream processing in agro-food industry. Amsterdam: Elsevier, pp 393-412

Gerasopoulos K, Stagos D, Petrotos K, Kokkas S, Kantas D, Goulas P, Kouretas D (2015) Feed supplemented with polyphenolic byproduct from olive mill wastewater processing improves the redox status in blood and tissues of piglets. Food Chem Toxicol 86:319-327

Gigliotti G, Proietti P, Said-Pullicino D, Nasini L, Pezzolla D, Rosati L, Porceddu PR (2012) Co- composting of olive husks with high moisture contents: organic matter dynamics and compost quality. Int Biodeterior Biodegradation 67:8-14

Gioffré D, Cannavò S, Smorto D (2004) Risultati sugli effetti delle acque reflue olearie somministrate con diverse modalità su terreno ulivetato in pieno campo e su piante di olivo allevate in mastello. In: Valorizzazione di acque reflue e sottoprodotti dell’industria agrumaria e olearia, Laruffa, pp 81-98

Gómez-Cruz I, del Mar Contreras M, Romero I, Castro E (2021) Recovery of antioxidant compounds from exhausted olive pomace through microwave-assisted extraction. Biol Life Sci Forum 6:62

González-González A, Cuadros F (2014) Effect of aerobic pretreatment on anaerobic digestion of olive mill wastewater (OMWW): an ecoefficient treatment. Food Bioprod Process 95:339-345

Greco G, Colarieti M, Toscano G, Iamarino G, Rao M, Gianfreda L (2006) Mitigation of olive mill wastewater toxicity. J Agric Food Chem 54:6776-6782

Guinda A, Castellano JM, Santos-Lozano JM, Delgado-Hervas T, Gutierrez-Adanez P, Rada M (2015) Determination of major bioactive compounds from olive leaf. LWT – Food Sci Technol 64:431-438

Haddad K, Jeguirim M, Jerbi B, Chouchene A, Dutournié P, Thevenin N, Ruidavets L, Jellali S, Limousy L (2017) Olive mill wastewater: from a pollutant to green fuels, agricultural water source and biofertilizer. ACS Sustain Chem Eng 5:8988-8996

Haddar W, Elksibi I, Meksi N, Mhenni MF (2014) Valorization of the leaves of fennel (Foeniculum vulgare) as natural dyes fixed on modified cotton: a dyeing process optimization based on a response surface methodology. Ind Crops Prod 52:588-596

Hadrich F, Geißen SU, Chamkha M, Sayadi S (2022) Optimizing the extraction conditions of hydroxytyrosol from olive leaves using a modified spherical activated carbon: a new experimental design. Biomed Res Int 17:6199627

Hanandeh AE, Albalasmeh A, Gharaibeh M, Alajlouni M (2021) Modification of biochar prepared from olive oil processing waste to enhance phenol removal from synthetic and olive mill wastewater. Sep Sci Technol 56:1659-1671

Hannachi H, Elfalleh W, Laajel M, Ennajeh I, Mechlouch R, Nagaz K (2020) Chemical profiles and antioxidant activities of leaf, pulp, and stone of cultivated and wild olive trees (Olea europaea L.). Int J Fruit Sci 20:350-370

Hazzaa R, Hussein M (2015) Adsorption of cationic dye from aqueous solution onto activated carbon prepared from olive stones. Environ Technol Innov 4:36-51

He J, Alister-Briggs M, de Lyster T, Jones G (2012) Stability and antioxidant potential of purified olive mill wastewater extracts. Food Chem 131(131):1312-1321

Hmid A, Mondelli D, Fiore S, Fanizzi FP, Chami ZA, Dumontet S (2014) Production and characterization of biochar from threephase olive mill waste through slow pyrolysis. Biomass Bioenergy 71:330-339

Hodaifa G, Ochando-Pulido J, Ben Driss Alami S, Rodriguez-Vives S, Martinez-Ferez A (2013a) Kinetic and thermodynamic parameters of iron adsorption onto olive stones. Ind Crop Prod 49:526-534

Hodaifa G, Sánchez S, Martínez ME, Órpez R (2013b) Biomass production of Scenedesmus obliquus from mixtures of urban and olive-oil mill wastewaters used as culture medium. Appl Energy 104:345-352

Hytiris N, Kapellakis I, De R, Tsagarakis K (2004) The potential use of olive mill sludge in solidification process. Resour Conserv Recycl 40:129-139

Innangi M, Niro E, D’Ascoli R, Danise T, Proietti P, Nasini L, Regni L, Castaldi S, Fioretto A (2017) Effects of olive pomace amendment on soil enzyme activities. Appl Soil Ecol 119:242-249

IOOC (2004) Recycling of vegetable water & olive pomace on agricultural land (

Isidori M, Lavorgna M, Nardelli A, Parrella A (2005) Model study on the effect of 15 phenolic olive mill wastewater constituents on seed germination and vibrio fischeri metabolism. J Agric Food Chem 53:8414-8417

Izghri Z, Enaime G, Louarrat M, Gaini LE, Baçaoui A, Yaacoubi A (2020) Novel catalyst from two-phase olive mill wastes using hydrothermal carbonisation for the removal of methylene blue by heterogeneous Fenton-like oxidation. Int J Environ Anal Chem 100:854-872

Jeguirim M, Chouchène A, Réguillon AF, Trouvé G, Buzit GL (2012) A new valorisation strategy of olive mill wastewater: impregnation on sawdust and combustion. Resour Conserv Recycl 59:4-8

Kambo H, Dutta A (2015) A comparative review of biochar and hydrochar in terms of production, physico- chemical properties and applications. Renew Sustain Energy Rev 45:359-378

Kavdir Y, Killi D (2007) Influence of olive oil solid waste applications on soil pH , electrical conductivity, soil nitrogen transformations, carbon content and aggregate stability. Bioresour Technol 99:2326-2332

Khosravi A, Zheng H, Liu Q, Hashemi M, Tang Y, Xing B (2022) Production and characterization of hydrochars and their application in soil improvement and environmental remediation. Chem Eng J 430:133142

Lafka TI, Lazou A, Sinanoglou V, Lazos E (2011) Phenolic and antioxidant potential of olive oil mill wastes. Food Chem 125:92-98

Lama-Muñoz A, Romero-García J, Cara C, Moya M, Castro E (2014) Low energy-demanding recovery of antioxidants and sugars from olive stones as preliminary steps in the biorefinery context. Ind Crops Prod 60:30-38

Larif M, Zarrouk A, Soulaymani A, Elmidaoui A (2013) New innovation in order to recover the polyphenols of olive mill wastewater extracts for use as a biopesticide against the Euphyllura olivina and Aphis citricola. Res Chem Intermed 39:4303-4313

Lodhi A (1976) Role of allelopathy as expressed by dominating trees in a lowland forest in controlling the productivity and patterns of herbaceous growth. Am J Bot 63:1-8

López F, Pinzi S, Ruiz J, López A, Dorado M (2010) Economic viability of the use of olive tree pruning as fuel for heating systems in public institutions in south Spain. Fuel 89:1386-1391

López-Piñeiro A, Fernández J, Nunes R, Manuel J, García Navarro A (2006) Response of soil and wheat crop to the application of two-phase olive mill waste to Mediterranean agricultural soils. Soil Sci 171:728-736

López-Piñeiro A, Murillo S, Barreto C, Muñoz A, Rato J, Albarrán A, García A (2007) Changes in organic matter and residual effect of amendment with two-phase olive mill waste on degraded agricultural soils. Sci Total Environ 378:84-89

Lykas C, Vagelas I, Gougoulias N (2014) Effect of olive mill wastewater on growth and bulb production of tulip plants infected by bulb diseases. Span J Agric Res 12:233

Majbar Z, Lahlou K, Abbou MB, Ammar E, Triki A, Abid W, Nawdali M, Bouka H, Taleb M, Haji ME, Rais Z (2018) Co-composting of olive mill waste and wine-processing waste: an application of compost as soil amendment. J Chem 2018:7918583

Makri S, Kafantaris I, Savva S, Ntanou P, Stagos D, Argyroulis I, Kotsampasi B, Christodoulou V, Gerasopoulos K, Petrotos K, Komiotis D, Kouretas D (2018) Novel feed including olive oil mill wastewater bioactive compounds enhanced the redox status of lambs. In Vivo 32:291-302

Maragkaki A, Vasileiadis I, Fountoulakis M, Kyriakou A, Lasaridi K, Manios T (2018) Improving biogas production from anaerobic co-digestion of sewage sludge with a thermal dried mixture of food waste, cheese whey and olive mill wastewater. Waste Manag 71:644-651

Markou G, Georgakakis D (2010) Balanced waste management of 2and 3-phase olive oil mills in relation to the seed oil extraction plant. Terr Aquat Environ Toxicol 4:109-112

Marks E, Mattana S, Alcañiz J, Pérez-Herrero E, Domene X (2016) Gasifier biochar effects on nutrient availability, organic matter mineralization, and soil fauna activity in a multi-year mediterranean trial. Agric Ecosyst Environ 215:30-39

Marks E, Kinigopoulou V, Akrout H, Azzaz A, Doulgeris C, Jellali S, Rad C, Sánchez Zulueta P, Tziritis E, El-Bassi L, Matei Ghimbeu C, Jeguirim M (2020) Potential for production of biochar-based

fertilizers from olive mill waste in mediterranean basin countries: an initial assessment for Spain, Tunisia, and Greece. Sustainabilit 12:6081

Martins D, Martins RC, Braga MEM (2021) Biocompounds recovery from olive mill wastewater by liquid-liquid extraction and integration with Fenton’s process for water reuse. Environ Sci Pollut Res 28:29521-29534

Massadeh MI, Modallal N (2008) Ethanol production from olive mill wastewater (OMW) pretreated with Pleurotus sajor-caju. Energy Fuels 22:150-154

Mata-Alvarez J, Dosta J, Romero-Güiza M, Fonoll X, Peces M, Astals S (2014) A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew Sust Energ Rev 36:412-427

Mechri B, Echbili A, Issaoui M, Braham M, Elhadj S, Hammami M (2007) Short-term effects in soil microbial community following agronomic application of olive mill wastewaters in a field of olive trees. Appl Soil Ecol 36:216-223

Medina E, Brenes M, Romero C, Garcia A, de Castro A (2007) Main antimicrobial compounds in table olives. J Agric Food Chem 55:9817-9823

Mekki A, Dhouib A, Sayadi S (2006a) Changes in microbial and soil properties following amendment with treated and untreated olive mill wastewater. Microbiol Res 161:93-101

Mekki H, Anderson M, Amar E, Skerratt G, BenZina M (2006b) Olive oil mill waste water as a replacement for fresh water in the manufacture of fired clay bricks. J Chem Technol Biotechnol 81:1419-1425

Meksi N, Haddar W, Hammami S, Mhenni M (2012) Olive mill wastewater: a potential source of natural dyes for textile dyeing. Ind Crops Prod 40:103-109

Messineo A, Maniscalco MP, Volpe R (2020) Biomethane recovery from olive mill residues through anaerobic digestion: a review of the state of the art technology. Sci Total Environ 703:135508

Michailides M, Christou G, Akratos CS, Tekerlekopoulou AG, Vayenas DV (2011) Composting of olive leaves and pomace from a three-phase olive mill plant. Int Biodeterior Biodegradation 65:560-564

Mikdame H, Kharmach E, Mtarfi N, Alaoui K, Ben Abbou M, Rokni Y, Majbar Z, Taleb M, Rais Z (2020) By-products of olive oil in the service of the deficiency of food antioxidants: the case of butter. J Food Qual 2020:1-10

Molina-Alcaide E, Yáñez-Ruiz D (2008) Potential use of olive byproducts in ruminant feeding: a review. Anim Feed Sci Technol 147:247-264

Molina-Alcaide E, Morales-García E, Martín-García A, Ben Salem H, Nefzaoui A, Sanz-Sampelayo M (2010) Effects of partial replacement of concentrate with feed blocks on nutrient utilization, microbial N flow, and milk yield and composition in goats. J Dairy Sci 93:2076-2087

Morillo JA, del Aguila VG, Aguilera M, Ramos-Cormenzana A, Monteoliva-Sanchez M (2007) Production and characterization of the exopolysaccharide produced by Paenibacillus jamilae grown on olive mill-waste waters. World J Microbiol Biotechnol 23:1705-1710

Murray A, Skene K, Haynes K (2015) The circular economy: An interdisciplinary exploration of the concept and application in a global context. J Bus Ethics 140:369-380

Naghmouchi I, Mutjé P, Boufi S (2015) Olive stones flour as reinforcement in polypropylene composites: a step forward in the valorization of the solid waste from the olive oil industry. Ind Crops Prod 72:183-191

Naisse C, Alexis M, Plante A, Wiedner K, Glaser B, Pozzi A, Carcaillet C, Criscuoli I, Rumpel C (2013) Can biochar and hydrochar stability be assessed with chemical methods? Org Geochem 60:40-44

Nakilcioğlu-Taş E, Otleş S (2019) The optimization of solid-liquid extraction of polyphenols from olive stone by response surface methodology. J Food Meas Charact 13:1497-1507

Nasini L, Gigliotti G, Balduccini M, Federici E, Cenci G, Proietti P (2013) Effect of solid olive-mill waste amendment on soil fertility and olive (Olea europaea 1.) tree activity. Agric Ecosyst Environ 164:292-297

Nasopoulou C, Zabetakis I (2013) Agricultural and aquacultural potential of olive pomace a review. J Agric Sci 5:116-127

Neshat S, Mohammadi M, Najafpour G, Lahijani P (2017) Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew Sust Energ Rev 79:308-322

Niaounakis M, Halvadakis C (2006) Olive processing waste management: literature review and patent survey. Typothito Publ., Athens, p 48

Nieto LM, Alami SBD, Hodaifa G, Faur C, Rodríguez S, Giménez JA, Ochando J (2010) Adsorption of iron on crude olive stones. Ind Crops Prod 32:467-471

Niknam SM, Kashaninejad M, Escudero I, Sanz MT, Beltrán S, Benito JM (2021) Valorization of olive mill solid residue through ultra-sound-assisted extraction and phenolics recovery by adsorption process. J Clean Prod 316:128340

Nikolaou A, Kourkoutas Y (2018) Exploitation of olive oil mill wastewaters and molasses for ethanol production using immobilized cells of Saccharomyces cerevisiae. Environ Sci Pollut Res 25:7401-7408

Ntaikou I, Kourmentza C, Koutrouli E, Stamatelatou K, Zampraka A, Kornaros M, Lyberatos G (2009) Exploitation of olive oil mill wastewater for combined biohydrogen and biopolymers production. Bioresour Technol 100:3724-3730

Ntougias S, Bourtzis K, Tsiamis G (2013) The microbiology of olive mill wastes. BioMed Res Int 2013(784591):16

Nunes L, Loureiro L, Sá L, Silva H (2020) Thermochemical conversion of olive oil industry waste: circular economy through energy recovery. Recycling 5:12

Nunzioa MD, Picone G, Pasini F, Cabonia MF, Gianotti A, Bordoni A, Capozzi F (2018) Olive oil industry by-products. Effects of a polyphenol-rich extract on the metabolome and response to inflammation in cultured intestinal cell. Food Res Int 113:392-400

Obied H, Allen M, Bedgood D, Prenzler P, Robards K, Stockmann R (2005) Bioactivity and analysis of biophenols recovered from olive mill waste. J Agric Food Chem 53:823-837

Oka Y, Yermiyahu U (2002) Suppressive effects of composts against the root-knot nematode Meloidogyne javanica on tomato. Nematology 4:891-898

Olmo M, Alburquerque J, Barrón V, del Campillo M, Gallardo A, Fuentes M, Villar R (2014) Wheat growth and yield responses to biochar addition under mediterranean climate conditions. Biol Fert Soils 50:1177-1187

Otero P, Garcia-Oliveira P, Carpena M, Barral-Martinez M, Chamorro F, Echave J, Garcia-Perez P, Cao H, Xiao J, Simal-Gandara J, Prieto M (2021) Applications of by-products from the olive oil processing: revalorization strategies based on target molecules and green extraction technologies. Trends Food Sci Technol 116:1084-1104

Ouzounidou G, Asfi M, Sotirakis N, Papadopoulou P, Gaitis F (2008) Olive mill waste-water triggered changes in physiology and nutritional quality of tomato (Lycopersicon esculentum Mill.) depending on growth substrate. J Hazard Mater 158:523-530

Padovani G, Pintucci C, Carlozzi P (2013) Dephenolization of stored olive-mill wastewater, using four different adsorbing matrices

to attain a low-cost feedstock for hydrogen photo-production. Bioresour Technol 138:172-179

Pardo T, Bernal P, Clemente R (2017) The use of olive mill waste to promote phytoremediation. In: Galanakis CM (ed) Olive mill waste: recent advances for the sustainable management. ElsevierAcademic Press, London, pp 183-204

Parkinson L, Cicerale S (2016) The health benefiting mechanisms of virgin olive oil phenolic compounds. Molecules 21:1-12

Pattara C, Cappelletti G, Cichelli A (2010) Recovery and use of olive stones. Commodity, environmental and economic assessment. Renew Sustain Energy Rev 14:1484-1489

Peña D, Fernández D, Albarrán A, Gómez S, Martín C, Sánchez-Terrón J, Vicente L, López-Piñeiro A (2022) Using olive mill waste compost with sprinkler irrigation as a strategy to achieve sustainable rice cropping under mediterranean conditions. Agron Sustain Dev 42:36

Peretz R, Mamane H, Wissotzky E, Sterenzon E, Gerchman Y (2021) Making cardboard and paper recycling more sustainable – recycled paper sludge for energy production and water-treatment applications. Waste Biomass Valori 12:1599-1608

Petrella A, Spasiano D, Acquafredda P, De Vietro N, Ranieri E, Cosma P, Rizzi V, Petruzzelli V, Petruzzelli D (2018) Heavy metals retention ( Pb (II), Cd (II), Ni (II)) from single and multimetal solutions by natural biosorbents from the olive oil milling operations. Process Saf Environ Protect 114:79-90

Plaza A, Tapia X, Yañez C, Vilches F, Candia O, Cabezas R, Romero J (2020) Obtaining hydroxytyrosol from olive mill waste using deep eutectic solvents and then supercritical

Poerschmann J, Baskyr I, Weiner B, Koehler R, Wedwitschka H, Kopinke FD (2013) Hydrothermal carbonization of olive mill wastewater. Bioresour Technol 133:581-588

Proietti P, Federici E, Fidati L, Scargetta S, Massaccesi L, Nasini L, Regni L, Ricci A, Cenci G, Gigliotti G (2015) Effects of amendment with oil mill waste and its derived-compost on soil chemical and microbiological characteristics and olive (olea europaea 1.) productivity. Agric Ecosyst Environ 207:51-60

Ramos-Cormenzana A, Monteoliva-Sanchez M, Lopez M (1995) Bioremediation of alpechin. Int Biodeterior Biodegrad 35:249-268

Regni L, Gigliotti G, Nasini L, Agrafioti E, Galanakis CM, Proietti P (2017) Reuse of olive mill waste as soil amendment. In: Galanakis CM (ed) Olive mill waste: recent advances for the sustainable management. Elsevier-Academic Press, London, pp 97-117

Rincon B, Borja R, Gonzalez J, Portillo M, Saiz-Jimenez C (2008) Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of onestage anaerobic digestion of two-phase olive mill solid residue. Biochem Eng J 40:253-261

Rodis PS, Karathanos V, Mantzavinou A (2002) Partitioning of olive oil antioxidants between oil and water phases. J Agric Food Chem 50:596-601

Rodrigues F, da Mota Nunes MA, Pinto Oliveira MBP (2017) Applications of recovered bioactive compounds in cosmetics and health care products. In: Galanakis CM (ed) Olive mill waste: recent advances for the sustainable management. Elsevier-Academic Press, London, pp 255-274

Rodrigues F, Pimentel F, Oliveira M (2015) Olive by-products: challenge application in cosmetic industry. Ind Crops Prod 70:116-124

Romero C, Medina E, Mateo M, Brenes M (2018) New by-products rich in bioactive substances from the olive oil mill processing. J Sci Food Agric 98:225-230

Rosello-Soto E, Koubaa M, Moubarik A, Lopes R, Saraiva J, Boussetta N, Grimi N, Barba F (2015) Emerging opportunities for the effective valorization of wastes and by-products generated during olive oil production process: non-conventional methods for the recovery of high-added value compounds. Trends Food Sci Technol 45:296-310

Rosen Y, Mamne H, Gerchman Y (2019) Short ozonation of lignocellulosic waste as energetically favorable pretreatment. BioEnergy Res 12:292-301

Rubio-Senent F, Rodríguez-Gutíerrez G, Lama-Muñoz A, FernándezBolaños J (2012) New phenolic compounds hydrothermally extracted from the olive oil byproduct alperujo and their antioxidative activities. J Agric Food Chem 60:1175-1186

Ruiz E, Romero-García J, Romero I, Manzanares P, Negro M, Castro E (2017) Olive-derived biomass as a source of energy and chemicals. Biofuels. Bioprod Bioref 11:1077-1094

Ryan D, Prenzler PD, Lavee S, Antolovich M, Robards K (2003) Quantitative changes in phenolic content during physiological development of the olive (Olea europaea) cultivar hardy’s mammoth. J Agric Food Chem 51:2532-2538

Saadi I, Laor Y, Raviv M, Medina S (2007) Land spreading of olive mill wastewater: effects on soil microbial activity and potential phytotoxicity. Chemosphere 66:75-83

Saleem J, Shahid U, Hijab M, Mackey H, McKay G (2019) Production and applications of activated carbons as adsorbents from olive stones. Biomass Convers Biorefin 9:775-802

Sánchez-Gutiérrez M, Bascón-Villegas I, Espinosa E, Carrasco E, Pérez-Rodríguez F, Rodríguez A (2021) Cellulose nanofibers from olive tree pruning as food packaging additive of a biodegradable film. Foods 10:1584

Sannino F, De Martino A, Capasso R, El Hadrami I (2013) Valorisation of organic matter in olive mill wastewaters: recovery of highly pure hydroxytyrosol. J Geochem Explor 129:34-39

Sar T, Akbas MY (2022) Potential use of olive oil mill wastewater for bacterial cellulose production. Bioengineered 13:7659-7669

Sasanelli N, D’Addabbo T, Mancini L (2011) Suppressive effect of composted olive mill wastes soil amendments on the root-knot nematode Meloidogyne incognita. Acta Hortic 914:229-231

Schmidt A, Knobloch M (2000) Olive oil-mill residues: the demonstration of an innovative system to treat wastewater and to make use of generated bioenergy and solid remainder. In: Proceedings of the 1st World Conference on Biomass for Energy and Industry, Seville, pp 452-454

Scoma A, Bertin L, Fava F (2013) Effect of hydraulic retention time on biohydrogen and volatile fatty acids production during acidogenic digestion of dephenolized olive mill wastewaters. Biomass Bioenergy 48:51-58

Serrano A, Fermoso FG, Alonso-Fariñas B, Rodríguez-Gutierrez G, Fernandez-Bolaños J, Borja R (2017) Olive mill solid waste biorefinery: high-temperature thermal pre-treatment for phenol recovery and biomethanization. J Clean Prod 148:314-323

Servili M, Esposto S, Veneziani G, Urbani S, Taticchi A, Maio I (2011a) Improvement of bioactive phenol content in virgin olive oil with an olive-vegetation water concentrate produced by membrane treatment. Food Chem 124:1308-1315

Servili M, Rizzello C, Taticchi A, Esposto S, Urbani S, Mazzacane F, Di Maio I, Selvaggini R, Gobbetti M, Di Cagno R (2011b) Functional milk beverage fortified with phenolic compounds extracted from olive vegetation water, and fermented with functional lactic acid bacteria. Int J Food Microbiol 147:45-52

Silvestri L, Forcina A, Di Bona G, C.S., (2021) Circular economy strategy of reusing olive mill wastewater in the ceramic industry: how the plant location can benefit environmental and economic performance. J Clean Prod 326:129388

Simonato B, Trevisan S, Tolve R, Favati F, Pasini G (2019) Pasta fortification with olive pomace: effects on the technological characteristics and nutritional properties. LWT-Food Sci Technol 114:108368

Sklavos S, Gatidou G, Stasinakis A, Haralambopoulos D (2015) Use of solar distillation for olive mill wastewater drying and recovery of polyphenolic compounds. J Environ Manag 162:46-52

Stasinakis A, Anastasios I, Constantinos VP, Halvadakis P (2008) Removal of total phenols from olive-mill wastewater using an agricultural by-product, olive pomace. J Hazard Mater 160:408-413

Tajada M, Gonzalez J (2004) Effects of application of a by-product of the two-step olive oil mill process on maize yield. Agron 96:692-699

Tarf OJ, Akça MO, Donar YO, Bilge S, Turgay OC, Sınağ A (2022) The short-term effects of pyro-and hydrochars derived from different organic wastes on some soil properties. Biomass Convers Biorefin 12:129-139

Tayeh HA, Azaizeh H, Gerchman Y (2020) Circular economy in olive oil production – olive mill solid waste to ethanol and heavy metal sorbent using microwave pretreatment. Waste Manag 113:321-328

Topal H, Atimtay A, Durmaz A (2003) Olive cake combustion in a circulating fluidized bed. Fuel 82:1049-1056

Toscano P, Montemurro F (2012) Olive mill by-products management. In: Olive germplasm-the olive cultivation, table olive and olive oil industry in Italy. InTech Open Access Publisher, pp 1-384

Troise A, Fiore A, Colantuono A, Kokkinidou S, Peterson D, Fogliano V (2014) Effect of olive mill wastewater phenol compounds on reactive carbonyl species and Maillard reaction end-products in ultrahigh-temperature-treated milk. J Agric Food Chem 62:10092-10100

Tzamaloukas O, Neofytou M, Simitzis P (2021) Application of olive by-products in livestock with emphasis on small ruminants: implications on rumen function, growth performance, milk and meat quality. Animals 11:531

Uddin MA, Siddiki SYA, Ahmed SF, Rony ZI, Chowdhury MAK, Mofijur M (2021) Estimation of sustainable bioenergy production from olive mill solid waste. Energies 14:7654

Veraa D, de Mena B, Jurado F, Schories G (2013) Study of a downdraft gasifier and gas engine fueled with olive oil industry wastes. Appl Therm Eng 51:119-129

Volpe M, Fiori L (2017) From olive waste to solid biofuel through hydrothermal carbonisation: the role of temperature and solid load on secondary char formation and hydrochar energy properties. J Anal Appl Pyrolysis 124:63-72

Volpe M, Wüst D, Merzari F, Lucian M, Andreottola G, Kruse A, Fiori L (2018) One stage olive mill waste streams valorisation via hydrothermal carbonisation. Waste Manag 80:224-234

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2011) Deactivation of cellulases by phenols. Enzyme Microb Technol 48:54-60

Yangui A, Abderrabba M (2018) Towards a high yield recovery of polyphenols from olive mill wastewater on activated carbon coated with milk proteins: experimental design and antioxidant activity. Food Chem 262:102-109

Yangui T, Dhouib A, Rhouma A, Sayadi S (2009) Potential of hydrox-ytyrosol-rich composition from olive mill wastewater as a natural disinfectant and its effect on seeds vigour response. Food Chem 117:1-8

Zahran H, El-Kalyoubi M, Khallaf M, Abdel-Razek A (2015) Improving oils stability during deep-fat frying using natural antioxidants extracted from olive leaves using different methods. Middle East J Appl Sci 5:26-38

Zheng Z, Liu J, Yuan X, Wang X, Zhu W, Yang F, Cui Z (2015) Effect of dairy manure to switchgrass co-digestion ratio on methane

production and the bacterial community in batch anaerobic digestion. Appl Energy 151:249-257

- Responsible Editor: Guilherme Luiz Dotto

Ghizlane Enaime

ghizlane.enaime@ruhr-uni-bochum.de

Institute of Urban Water Management and Environmental Engineering, Ruhr-Universität Bochum, Universitätsstraße 150, 44780 Bochum, Germany

DOI: https://doi.org/10.1007/s11356-024-32468-x

PMID: https://pubmed.ncbi.nlm.nih.gov/38407704

Publication Date: 2024-02-26

Olive mill wastes: from wastes to resources

© The Author(s) 2024

Abstract

Olive oil extraction has recently experienced a continuous increase due to its related beneficial properties. Consequently, large amounts of olive mill wastes (OMWs) derived from the trituration process are annually produced, causing serious environmental problems. The limited financial capabilities of olive mills make them usually unable to bear the high costs required for the disposal of their wastes. Alternatively, the valorization of OMWs within the framework of the so-called waste-to-resource concept and their recycling can represent a successful strategy for the implementation of circular economy model in the olive industry, which could have significant socioeconomic impacts on low-income Mediterranean countries. There is, however, no unique solution for OMWs valorization, due to the wide variety of the wastes’ composition and their seasonal production. In this review, the potential of OMWs for being reused and the recent technological advances in the field of OMWs valorization are assessed. Special focus is given to the analysis of the advantages and limitations of each technology and to reporting the most significant issues that still limiting its industrial scale-up. The information collected in this review shows that OMW could be effectively exploited in several sectors, including energy production and agriculture. OMWs potential seems, however, undervalued, and the implementation of sustainable valorization strategies in large-scale remains challenging. More efforts and policy actions, through collective actions, encouraging subsidies, and establishing public-private collaborations, are still needed to reconcile research progress with industrial practices and encourage the large-scale implementation of the waste-to-resource concept in the olive sector.

Introduction

biofertilizer and soil amendments (Messineo et al. 2020; Uddin et al. 2021). OMWs can also be reused as growth medium for algae (Hodaifa et al. 2013b), as additive incorporated into construction materials (Hytiris et al. 2004), and to produce biopolymeric substance (Ntaikou et al. 2009). Despite the promising results obtained regarding the valorization of OMWs and their conversion into valuable resources, the large-scale application of the suggested methods is still limited for many technical and economic considerations. This contribution summarizes the key research investigations reporting on the valorization of OWMs and their use as resources instead of their treatment as wastes. Specific questions were as follows: What are the drivers and characteristics of the potential implementation of the new concept of wastes to resources in olive sector? What is the current knowledge related to this issue? What are the main limitations hindering the large adoption of this promising strategy and what are the future prospects?

Olive mill wastes utilization techniques

OMWs as source of energy

Thermochemical methods

also observed due to the high content of OMSW in volatile matter. Topal et al. (2003) compared the combustion efficiency of olive cake and lignite coal treated separately and their co-combustion in a circulating fluidized bed. The results showed that CO and

| By-product | Valorization method | Produced resource | Application | Main findings | Reference | ||||

| Olive pomace | Solvent extraction | Pomace oil | Food industry | Allow cooking at high temperatures | Donner et al. (2022) | ||||

| Olive pomace | – | Flour and microparticles of olive pomace | Addition to chitosan-based films |

|

De Moraes Crizel et al. (2018) | ||||

| Olive pomace | – | – | Fortification of pasta with olive pomace |

|

Simonato et al. (2019) | ||||

| Olive pomace | – | – | Adsorption of textile dye from aqueous solution | More than 80% of textile dye was removed | Akar et al. (2009) | ||||

| OMSW | Anaerobic co-digestion of OMSW with microalgae (D. Salina) | – | Biogas production | Maximum methane ( 330 mL

|

Fernández-Rodríguez et al. ( 2014, 2021) | ||||

| TPOMW | Co-digestion of NaOH -pretreated TPOMW with food waste | – | Biogas production | The

|

Al-Mallahi et al. (2016) | ||||

| Olive stones | Drying grinding | Olive stones flour | Reinforcement filler of plastic materials | Enhancement in flexural strength and water barrier properties | Naghmouchi et al. (2015) | ||||

| Olive leaves | Liquid-liquid extraction | Natural antioxidants extracts | Addition to sunflower oil, soybean oil, and their blend | Increase in the stability of the studied oils | Zahran et al. (2015) | ||||

| Olive pomace and OMWW | Methanol extraction | Phenolic compounds | Enrichment of butter | High resistance against oxidative stress during storage | Mikdame et al. (2020) |

| By-product | Valorization method | Produced resource | Application | Main findings | Reference | ||||

| OMWW and OMWWimpregnated biomass (sawdust and wood chips) | Convective drying and condensation | Recovered-condensed water | – |

|

Dutournié et al. (2019) | ||||

| Olive Tree Pruning | Solvent casting method | Biodegradable packaging film | Food packaging biopolymer |

|

Sánchez-Gutiérrez et al. (2021) | ||||

| Pruning biomass | Valorization in two processing plants: antioxidant plant (liquid-liquid extraction) and bioethanol plant (saccharification and fermentation) | Natural antioxidants and ethanol | Production of energy and high added value products | Ethanol (

|

Romero-García et al. (2016) | ||||

| OMWW and exhausted OMSW | Impregnation of exhausted OMSW with OMWW | Solid biofuel | Combustion | Increase in energy content and reactivity of exhausted OMSW following OMWW addition | Jeguirim et al. (2012) | ||||

| OMWW | – | – | Alternative wetting agent | No significant difference observed for substrate containing 25% OMWW compared to control group | Kalmis et al. (2008) | ||||

| OMWW | Combination of solar drying and composting | Organic fertilizer (57% organic carbon,

|

Use as organic fertilizer for cultivation of pepper plants | Fertility similar to commercial NPK fertilizers | Galliou et al. (2018) |

| Table 1 (continued) | ||||||||

| By-product | Valorization method | Produced resource | Application | Main findings | Reference | |||

| OMWW | – | – | Feed additive to a silage formulation for lambs |

|

Makri et al. (2018) | |||

| OMWW | – | Phenolic compounds | UV filters in sunscreens | Olive phenols are more active UV filters in a broader region of UVB and UVA | Galanakis et al. (2018) | |||

| OMWW | Ceramic membrane microfiltration | Polyphenols | Feed supplement for piglets |

|

Gerasopoulos et al. (2015) | |||

| OMWW mixed with molasses | Fermentation | – | Ethanol production | Ethanol concentration and daily productivity values recorded at temperatures

|

Nikolaou and Kourkoutas (2018) | |||

| OMWW | Fermentation of OMWW by P. jamilae (a Gram-positive bacteria isolated from OMWW based compost) | Exopolysaccharide (polymer) | Biotechnological interest due to its possible application as heavy metal biosorbent | Appreciable amount of extracellular polysaccharide (

|

Morillo et al. (2007) | |||

| OMWW | Yeast fermentation | – | Ethanol production | Maximum ethanol production (

|

Massadeh and Modallal (2008) | |||

| OMWW | Bacterial strain cultivation in OMWW | Bacterial cellulose | – | Enrichment of OMWW medium (%100) with yeast extract (

|

Sar and Akbas (2022) | |||

| Table 1 (continued) | |||||

| By-product | Valorization method | Produced resource | Application | Main findings | Reference |

| OMWW | – | Natural dyes for textile industry | Dye bath for dyeing wool | Considerable color fastness properties for acrylic fiber | Haddar et al. (2014) |

| Olive vegetation water | – | Phenolic compounds | Fortification of milk beverages (similar to yogurt) | – | Servili et al. (2011b) |

| VS volatile solids | |||||

Biochemical methods

(2019), which consisted of the filtration of OMWW on olive stones followed by coagulation-flocculation as a second pretreatment step. This combined pretreatment process resulted in a total suspended solid and fatty matter depletion of about

was achieved when mixed with cheese whey. Interestingly is the co-digestion of OMWW with OMSW as both streams are a problematic issue for olive mill operators and OMSW is a substrate rich in nitrogen (

accessibility as compared to the alkaline post-treatment. In a study performed by Najafi et al. (2021), an integrated process regrouping fermentation, anaerobic digestion of fermentation residues, and lignin production was performed. In the same, study three different pretreatments have been tested, namely liquid hot water, organosolv, and acid-catalyzed organosolv. By using this combined process, authors reported a production of 295.5 L bioethanol,

highly concentrated OMWW. The simultaneous production of bioethanol and biohydrogen from OMWW-olive pomace mixture using Saccharomyces cerevisiae anaerobic fermentation was also investigated by Battista et al. (2016). Authors studied several pretreatments (ultrasonic pretreatment, basic pretreatment, and calcium carbonate addition) to improve glucose release and then enhance bioethanol and biohydrogen production and simultaneously reduce the inhibiting effect of polyphenols on the fermentation process. The results showed that all the pretreatment methods improved bioethanol and biohydrogen production yields, with basic and ultrasonic pretreatments resulted in the highest bioethanol and biohydrogen concentration, due to their contribution in improving the hydrolysis of lignin and cellulose and in increasing the soluble sugars (in particular glucose) content in the reaction mixture.

Application of OMWs in agriculture

Direct spreading of OMWs in soil

was reported significantly reduced after few months, due to the production of ammonia resulting from the bacterial breakdown of OMWW organic matter and the buffering capacity of soil (Regni et al. 2017). The effect of OMWW spreading on soil microbiology is due not only to the variation in the soil pH , but also to the contribution of OMWW organic matter, which induces an increase in the soil microflora. Mekki et al. (2006a) reported a significant increase in soil actinomycetes, spore-forming bacteria and soil fungi and a significant reduction in the number of soil nitrifying bacteria. Similarly, Mechri et al. (2007) observed an increase in soil fungi, Gram-negative bacteria and actinomycetes after the addition of more than

can be used for agronomic purposes (Toscano and Montemurro 2012). Other than being economical and easily practicable management method for olive mill operator, it has been reported conferring considerable benefits for soil characteristics and crops productivity. Kavdir and Killi (2007) demonstrated that soil amendment with pomace improves its water holding capacity, structure, and stability, making it less susceptible to erosion. The incorporation of olive pomace in soil increases its organic matter and enhanced its biological activity, without detectable negative effects on pH value and salinity (Regni et al. 2017; Innangi et al. 2017). The effect of pomace application on soil organic matter is strongly depending on the application method. Nasini et al. (2013) proceeded to the spreading of large amounts of pomace (

on the oil content. The positive effect of OMWs spreading on soil and crops is conditioned by the respect of the maximum spreading load and the correct spreading technique and time. López-Piñeiro et al. (2007) reported that the optimal spreading period is corresponding to the period before the resumption of vegetative growth. The spreading load could be higher when OMWs are applied on tree crops such as olive tree. Additionally, the nature of OMWs is also an important factor in determining the spreading load. In Italy, the agronomic use of OMWW derived from traditional extraction systems is allowed up to

OMWs composting

Application of OMWs-derived biochar/hydrochar as soil amendment