DOI: https://doi.org/10.1007/s40789-025-00775-4

تاريخ النشر: 2025-04-19

نحو الحياد الكربوني: دراسة شاملة حول استخدام واستعادة الموارد من النفايات الصلبة المعتمدة على الفحم

© المؤلفون 2025

الملخص

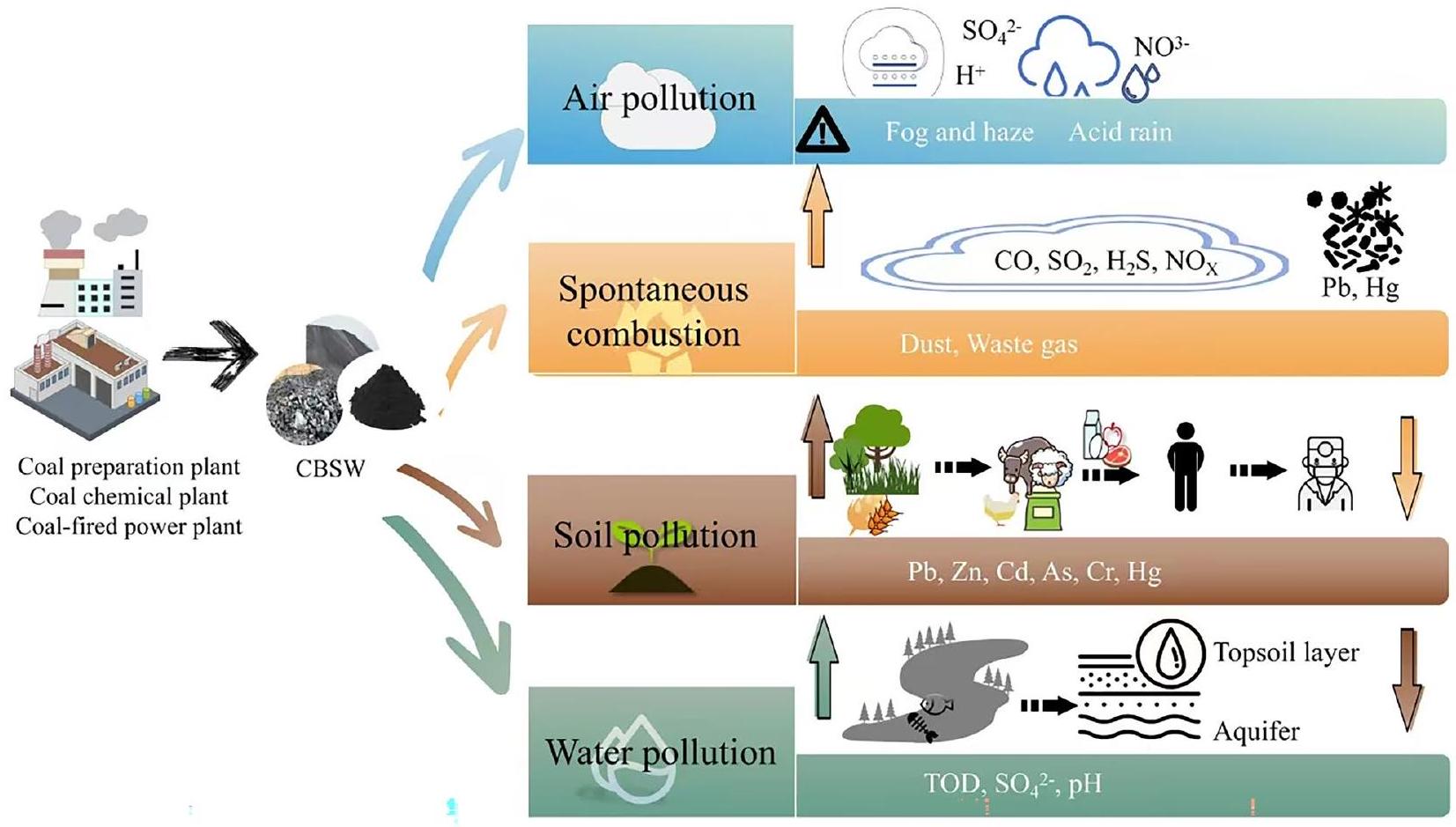

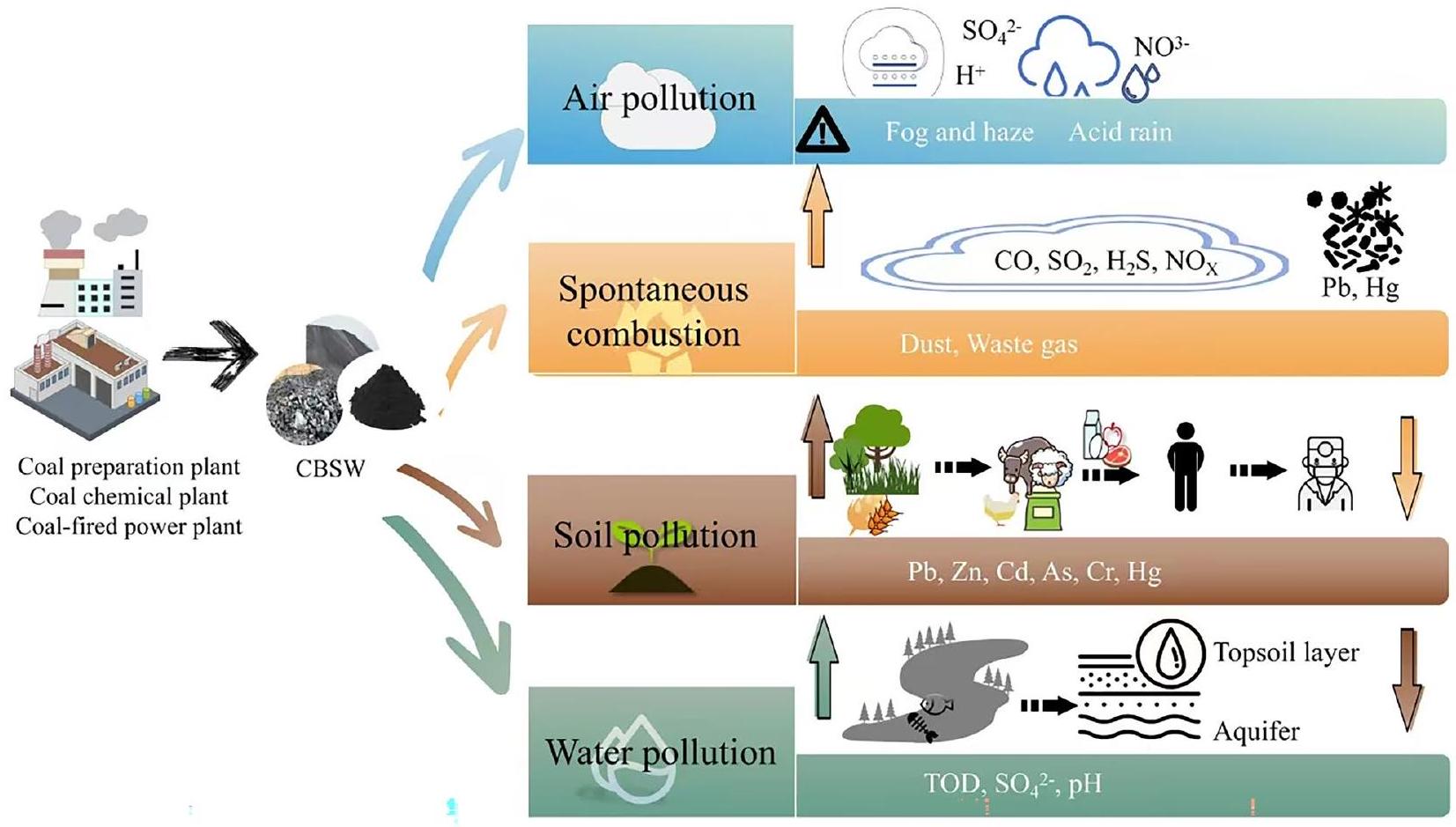

النفايات الصلبة المعتمدة على الفحم (CBSWs) هي منتجات ثانوية صناعية يمكن أن تكون ضارة بالبيئة. إن استغلال واستخدام CBSWs يوفر مزايا اجتماعية مثل الحفاظ على الموارد، وتقليل التلوث، وإنتاج بتكلفة فعالة. ومع ذلك، لا يزال الإدارة المستدامة بيئيًا تمثل تحديًا عالميًا بسبب حجم الإنتاج الكبير وسعة التخلص المحدودة من CBSWs. يتم تلخيص الخصائص الفيزيائية والكيميائية واستخدام CBSWs، بما في ذلك الرماد المتطاير، ونفايات الفحم، وخبث الغازification الفحم. كما يقدم الحالة الحالية للتطبيقات العالمية لموارد CBSWs ويفحص العرض والطلب في السوق. بعد ذلك، يقدم البحث نظرة عامة على الدراسات حول طرق استخدام CBSWs، مع تسليط الضوء على الطرق الرئيسية لاستغلال موارد CBSWs التي تأتي أساسًا من مجالات المواد الكيميائية، والمعادن، والزراعة. علاوة على ذلك، يتم إجراء تقييم مقارن لطرق استعادة موارد CBSWs المختلفة، موضحًا مزاياها وعيوبها. كما يتم مناقشة التطور المستقبلي لعمليات إعادة تدوير CBSWs. يستنتج المراجعة أنه بينما هناك حاجة متزايدة للاهتمام في إعادة تدوير CBSWs، فإن استخدامها سيتطلب مزيجًا من عمليات المعالجة الكبيرة والنقية. يهدف البحث إلى تقديم مراجع ورؤى للاستخدام الفعال وحماية البيئة لـ CBSWs. ستركز الاتجاهات المستقبلية على الاستخدام التعاوني لـ CBSWs، مع التأكيد على الجمع بين الاستخدام الكبير والقيمة العالية. بالإضافة إلى ذلك، هناك حاجة لإنشاء قاعدة بيانات شاملة تعتمد على ممارسات الإنتاج في الموقع، واستكشاف الحلول في الموقع لتقليل تكاليف النقل، وتحسين الخصائص الفيزيائية والكيميائية خلال عملية الإنتاج.

1 المقدمة

2 خصائص النفايات الصلبة المعتمدة على الفحم

2.1 نفايات الفحم

تمثل

2.2 الرماد المتطاير

تختلف معدلات الاستخدام بشكل كبير بين الدول، حيث تتراوح من 99% في اليابان إلى 11% فقط في إفريقيا والشرق الأوسط (Jin et al. 2021; Xu and Zuo 2018). في عام 2021، بلغ إنتاج FA في الصين 7.9 مليار طن (Chen et al. 2024)، مع زيادة متوقعة إلى 9.25 مليار طن بحلول عام 2024 (Zhang

| طريقة الاستخدام | معدل استخدام FA (%) | |||

| الصين | أمريكا | اليابان | الاتحاد الأوروبي | |

| مواد البناء | 64 | 33.05 | 67.12 | 90.8 |

| ملء المناجم | 20 | 28.92 | 10.31 | |

| معالجة مياه الصرف | 9 | 23.77 | 22.88 | 9.2 |

| تعديل التربة | 7 | 14.26 | ||

2.3 خبث غاز الفحم

تُلقى الغالبية العظمى من CGS ببساطة أو تُدفن في المدافن. في عام 2019، تجاوزت انبعاثات CGS في الصين 35 مليون طن، مع معدل استخدام شامل يبلغ فقط

| مكون/ محتوى | سي جي | فا | CGS |

|

|

٤٤.٧٨~٦١.٧٠ | ٣٣.٩٠~٥٩.٧٠ | 14.86~53.36 |

|

|

15.53~39.05 | 16.50~35.40 | 7.72~16.81 |

|

|

|

1.50 ~ 15.40 | 7.37~41.19 |

| أكسيد الكالسيوم | 0.33~4.14 |

|

6.79~19.04 |

| أكسيد المغنيسيوم |

|

|

0.86~2.40 |

|

|

|

|

– |

|

|

– |

|

1.55~3.22 |

|

|

– |

|

– |

| يضحك بصوت عالٍ | 13.99~16.30 | 1.20~23.50 | 1.19~52.91 |

| نوع | التكوين الرئيسي | التكوين الثانوي | أنماط الاستخدام | ||||

| سي جي |

|

|

تعديلات التربة، المواد الكيميائية الخام القائمة على الألمنيوم، المنتجات الكيميائية القائمة على السيليكون والمواد الخام الخزفية، المواد الماصة، الأسمنت، الطوب والمواد الجدارية الجديدة | ||||

| فا |

|

|

الأسمنت، الخرسانة، تصنيع الجدران والطلاءات الوظيفية، تصنيع الأسمدة الزراعية، المواد الماصة، سيليكات الماء، إنشاء الطرق وملء مناطق هبوط تعدين الفحم | ||||

| CGS | الطور غير المتبلور | الطور البلوري |

|

||||

| الألومينوسيليكات غير المتبلور، الكربونية | الكوارز، الموليت، الجالينايت والكلسيت | مادة هلامية |

3 تطبيقات CBSWs في مجال المواد الكيميائية

3.1 مواد البناء

3.1.1 الأسمنت

3.1.2 الخرسانة

المحتوى. في دراسة أخرى، قام شيانغ وآخرون (2022) بالتحقيق في استخدام الرماد المتطاير كإضافة معدنية وCGS لاستبدال الرمل الطبيعي في تحضير خرسانة الرماد المتطاير. أظهرت نتائج هذه الدراسة زيادة في درجة كثافة الخرسانة مع إضافة

3.1.3 مواد الجدران

معدل مادة التعبئة السائلة يتغير مع محتوى CGS. مع زيادة محتوى CGA، انخفض معدل إزالة الماء من CGS.

3.1.4 المواد الخزفية

3.1.5 الزجاجيات السيراميكية

مُتبلور عند

3.1.6 الجيوبوليمر

3.1.7 مواد الموليت

| مواد الموليت | التطبيقات |

| المواد المقاومة للحرارة | مواد البناء، المعادن، النفط، الصناعة الكيميائية، الآلات، السيراميك، الطاقة الكهربائية، الطيران، إلخ |

| مواد الطلاء | المعادن، السيراميك، الفضاء، المعادن، التحفيز، إلخ |

| مواد التعزيز | صناعة كيميائية، طاقة كهربائية، تعدين، آلات، إلخ |

| مواد مقاومة للاحتكاك | مواد البناء، المواد الكيميائية، الآلات، إلخ |

| مواد الفلترة | معالجة المياه، الطاقة الكهربائية، الصناعة الكيميائية، الآلات، إلخ |

3.2 المواد الوظيفية

3.2.1 مواد الامتزاز

3.2.2 مواد امتصاص الموجات الكهرومغناطيسية

موصلية كهربائية ممتازة. الكربون المتبقي الموجود في CBSWs ليس فقط مسامي وجزئيًا متحجر، ولكنه يمتلك بنية مسامية تسمح بانعكاس وامتصاص متعدد للموجات الكهرومغناطيسية. تبرز هذه المزايا إمكانيته كمواد خام لمواد امتصاص الموجات (Li et al. 2023c). أعد Lin et al. (2023) مواد امتصاص الموجات من رغوة الكربون البيروليتي باستخدام طريقة الجسم المُصنّع مسبقًا مع عملية التحلل الحراري. وجدت الدراسة أن مواد رغوة الكربون البيروليتي مناسبة كمواد لامتصاص الموجات ضمن نطاق درجات الحرارة

3.2.3 غربال جزيئي من الزيوليت

طريقة الهيدروحرارية التقليدية. بالإضافة إلى ذلك، يمكن أن يقلل استخدام الميكروويف من وقت التفاعل ودرجة الحرارة، مما يعزز بلورة المنتجات. استخدم جيانغ وآخرون (جيانغ 2022ب) معالجة ذوبان القلويات الساخنة – استخراج الحمض لتخليق غربال جزيئي ZSM-5، مع الظروف المثلى كما يلي: درجة حرارة التحميص

3.2.4 المحفزات وحوامل المحفزات

عبر الطريقة الهيدروحرارية وأظهرت النتائج أن أداء التحفيز الضوئي للحمولة

3.2.5 المركبات

3.2.6 السيليكا

| مسار الاستخدام | المنتجات | المزايا | العيوب | المراجع |

| مواد البناء | أسمنت | يساهم في تفاعل ترطيب الأسمنت، ويقلل من زمن التصلب، ويحسن من قوة الضغط ومقاومة التشقق. | يتطلب معالجة بالتكلس، ومتطلبات صارمة على كمية الفقد عند الاحتراق، وظروف تفاعل قاسية | وانغ (2022ج)، قوه وآخرون (2022ب)، هي وآخرون (2022ب) |

| خرسانة | يعزز قوة الضغط ومقاومة التشقق بالإضافة إلى مقاومة الصقيع | يتطلب معالجة مثل السحق، والفرز، والمعالجة الحرارية | وانغ (2022د)، لي (2022)، ما (2022) | |

| مواد الجدران | العزل الحراري، توفير الطاقة وتقليل النفايات، زيادة الكثافة والمتانة | عملية معقدة، استثمار عالي، تكلفة عالية، وفي مرحلة البحث التجريبي | هوانغ (2022) | |

| المواد الخزفية | الاستفادة من المحتوى المعدني غير العضوي الغني في نفايات الفحم | عملية معقدة، تكلفة عالية | يان وآخرون (2023ب)، تشين (2015)، تشين (2012)، وي ووانغ (2010) | |

| السيراميك الزجاجي | تكلفة منخفضة واستخدام عالي | تتطلب درجات حرارة أعلى والعائد غير مستقر | ماو وآخرون (2022)، زينغ وسون (2022)، لو وآخرون (2022)، سون وآخرون (2016)، دانغ وهي (2020) | |

| جيوبوليمر | عملية بسيطة، استخدام عالي | الجيوبوليمرات الاصطناعية أقل استقرارًا وأكثر تكلفة | وانغ وآخرون (2023ج)، وانغ وآخرون (2022ب)، تشاو وآخرون (2022أ)، لي وآخرون (2021ب)، تشانغ وآخرون (2020)، رشاد وآخرون (2023)، ليكشمي وسودهاكومار (2022) | |

| مواد الموليت | سهولة الحصول على المواد الخام، تعالج مشكلة الموليت الطبيعي المحدود، قوة انحناء عالية، مقاومة جيدة للتآكل | يتطلب معالجة مسبقة لتقليل المرحلة الزجاجية ولإذابة الشوائب | ليو وآخرون (2021ب)؛ وانغ وآخرون (2021) | |

| المواد الوظيفية | مواد الامتزاز | مساحة سطح محددة كبيرة وبنية مسامية غنية | يتطلب عملية الكلسنة | ليو وآخرون (2017)، كمان وآخرون (2023)، عبد السلام وآخرون (2020) |

| مواد امتصاص الموجات الكهرومغناطيسية | رخيص، كثافة منخفضة | يتطلب الأمر التوظيف أو التمعدن؛ لا تزال هناك نطاقات امتصاص ضيقة نسبيًا، وكفاءة امتصاص منخفضة، وتوافق كهرومغناطيسي ضعيف. | تشانغ وآخرون (2019) | |

| منخل جزيئي زيولايت | طريقة بسيطة للإنتاج الضخم | يجب التحكم بدقة في ظروف التفاعل، والجودة المطلوبة للـ CBSWs عالية. | تشو وآخرون (2022)، فان وآخرون (2021) | |

| المحفزات وحوامل المحفزات | متناثر ومسامي، جيد لتحضير المحفزات، حامل جيد | نقص النضج التكنولوجي | لو وآخرون (2020)، دو وآخرون (2022)، دو وآخرون (2021) | |

| المركبات | الاستجابة لارتفاع تكاليف المواد | علاج معقد ومكلف للمتبقيات والسوائل النفايات | بيتايافيني وآخرون (2023) | |

| سيليكا | الحفاظ على المواد الخام الكيميائية، تقليل التكاليف، تخفيف الضغط الناتج عن النفايات الصلبة للفحم على البيئة، زيادة القيمة المضافة للمنتجات، وتمديد سلسلة صناعة الفحم | يتطلب التحكم في خصائص المعادن وتفعيلها. شروط لمخلفات أنظمة الفحم المختلفة، والعملية معقدة وتستهلك الطاقة. | كون وآخرون (2013) |

4 تطبيق CBSWs في علم المعادن

4.1 استخراج الألمنيوم

نسبة السائل إلى الصلب

4.2 استخراج الغاليوم

| طرق | عمليات محددة | المزايا | العيوب |

| طريقة القلوي | تحميص القلويات قبل إزالة الرطوبة | معدل استخراج الألمنيوم العالي | استهلاك عالي للطاقة، كمية كبيرة من المخلفات، استهلاك عالي للقواعد |

| طريقة الحمض | تفعيل – حامض – استخراج – تكليس | استهلاك منخفض للطاقة، كمية منخفضة من بقايا النفايات | تآكل خطير في المعدات وعملية إزالة التلوث المعقدة |

| الطريقة الهيدروكيميائية | عملية كيمياء التحميص بالماء NaOH | معدل استخراج الألمنيوم العالي، استهلاك الطاقة المنخفض، بقايا السيليكا؛ سهل التحلل | تركيز عالٍ من القلويات، ضعف تدفق الملاط، وزيادة استهلاك المواد |

| طريقة تقليل الضغط | عملية الاختزال الحراري في الفراغ | تقريبًا لا توجد ملوثات ثانوية، حماية بيئية خضراء | لا يزال في مرحلة البحث في المختبر |

| كلورنة حرارية بالكربون | عملية الكلورنة الحرارية للكربون | تقريبًا لا توجد ملوثات ثانوية، تتيح العملية استخدام غاز الكلور كمواد أولية في الدورة والاستخراج المتزامن للسيليكون والكالسيوم والتيتانيوم. | لا يزال في مرحلة البحث في المختبر |

| طرق | نظرية | المزايا | العيوب | المراجع |

| الامتزاز | تقوم المجموعات الوظيفية على هيكل الممتز بامتصاص أيونات الغاليوم في المحلول، مما يفصل أيونات الغاليوم عن الشوائب أو أيونات الشوائب الموجودة في المحلول. | استرداد عالي للغاليوم، عملية بسيطة، لا متطلبات خاصة للإنتاج الصناعي | المواد الممتصة مكلفة وصعبة الإنتاج. | لي (2013) |

| ترسيب | يستفيد من الكثافات المختلفة والترسب تحت تأثير الجاذبية | بسيط ومريح، منخفض التكلفة، تقنية ناضجة | تتطلب العملية عدة ترسبات، مما يستغرق وقتًا طويلاً، ويتأثر بسهولة بأيونات الشوائب الأخرى، ونقاء الغاليوم المستخرج منخفض. | دوان وآخرون (2016) |

| استخراج | يمكن استغلال الفرق في الذوبانية أو معامل التقسيم للعنصر المستهدف في مذيبين غير قابلين للامتزاج لنقل العنصر المستهدف أو الشوائب بشكل انتقائي. | عملية بسيطة، تستخدم بشكل رئيسي لاستخراج الغاليوم في محلول الحامض. | فقدان المذيب وتلوث السائل المستخرج | هان وآخرون (2022أ)، لياو وآخرون (2017) |

| طريقة تبادل الأيونات | يتم استخراج أو إزالة بعض الأيونات من محلول عن طريق تبادل الأيونات في مبادل أيوني صلب مع أيونات محددة في محلول مخفف. | عملية بسيطة، استثمار صغير في المعدات | سعر الصرف منخفض، ودورة الإنتاج طويلة، ويتم إنتاج كمية كبيرة من سائل نفايات التجديد. | وانغ وزانغ (2019) |

| التحليل الكهربائي غونزي | يتم استخراج الغاليوم عن طريق التحليل الكهربائي من المواد التي تحتوي على الغاليوم.

|

يمكن استخراج الغاليوم مباشرة ويمكن الحصول على نقاء عالٍ من الغاليوم المعدني. | استهلاك الزئبق العالي، تلوث الزئبق في بيئة العمل، التأثيرات السلبية على صحة الإنسان، قد يكون الاستخدام العملي محدودًا | لو وآخرون (2008) |

| طريقة فيلم المستحلب | من خلال التفاعل بين واجهتين لمحلولين أو أكثر من تركيبات مختلفة تكون قابلة للذوبان في بعضها البعض | فعال وسريع وموفر للطاقة، خاصة في فصل المكونات ذات التركيز المنخفض | لا يزال تطبيق استخراج الغاليوم من مياه الصرف الصناعي في مرحلة البحث. | هوانغ وآخرون (2017) |

4.3 استخراج الليثيوم

4.4 استخراج التيتانيوم

| الجدول 8 خصائص عمليات استخراج الليثيوم المختلفة | ||||

| طرق | العملية التكنولوجية | المزايا | العيوب | تأثير على استخراج الرشح |

| طريقة التحميض | عملية استخراج الحمض المباشر؛ عملية التلبيد – عملية استخراج الحمض | عملية بسيطة، استهلاك منخفض للطاقة والتكلفة | من الصعب الحصول على معدلات تسرب عالية لرماد الفحم المسحوق ذو النشاط المنخفض لليثيوم، وهو قابل للتطبيق فقط على رماد السرير المميع، الذي يتطلب تدفق عملية طويل، واستهلاك طاقة مرتفع وتكلفة عالية. | تركيب معقد لمحلول التسرب الحمضي، استخراج الليثيوم صعب |

| طريقة القلوي | عملية ما قبل إزالة الرطوبة – التلبيد – التصفية | مماثل لطريقة باير التقليدية وهذه العملية ناضجة نسبيًا | تركيب معقد لمحلول التسرب الحمضي، استخراج الليثيوم صعب | محلول إزالة السيليكا، والشوائب في محلول التصفية بسيطة، واستخراج الليثيوم سهل نسبيًا |

| طرق أخرى | عملية الحمض-القاعدة المدمجة؛ عملية استخراج القلويات المستمرة متعددة الخطوات بالتدفق المعاكس | معدل استخراج أعلى واستهلاك طاقة أقل | لا تزال في مرحلة الدراسات التجريبية الصغيرة على نطاق المختبر | المياه الناتجة تحتوي على عناصر شوائب أقل، ومن الأسهل استخراج الليثيوم. |

4.5 استخراج عناصر الأرض النادرة

5 تطبيقات CBSWs في الزراعة

5.1 تعديل التربة

| تقنيات | نظرية | المزايا | العيوب |

| ترسيب كيميائي | فصل العناصر الأرضية النادرة وفقًا لذوبانها في المذيبات | معدات بسيطة وسهلة التشغيل | تكلفة عالية، معدل فصل منخفض، تلوث بيئي عالي |

| طرق تبادل الأيونات والامتزاز | يمكن فصل العناصر الأرضية النادرة عن طريق الامتزاز على الراتنج والتفاعل مع المستخلص في الراتنج. | كفاءة فصل جيدة، نقاء عالٍ، تلوث منخفض | وقت دورة طويل، سعة علاج منخفضة، تكلفة عالية |

| كروماتوغرافيا الاستخراج | فصل العناصر الأرضية النادرة بسبب اختلاف معاملات التقسيم في الطور الصلب-السائل | معدات بسيطة، انتقائية جيدة وكفاءة عالية | استهلاك عالي للأحماض، المستخرج يمكن إزالته بسهولة |

| استخراج بالمذيب | فصل العناصر الأرضية النادرة في الطورين المائي والعضوي من خلال تأثير المستخلصات ذات القابلية المختلفة للذوبان أو معاملات التقسيم | انتقائية جيدة، سعة معالجة كبيرة، نقاء عالٍ، عملية مستمرة | تكلفة عالية، استهلاك طاقة مرتفع، سمية عالية لبعض المذيبات |

| فصل الغشاء السائل | الاستخراج والعكس عبر الأغشية القابلة للاختراق الانتقائي | كفاءة عالية، طريقة بسيطة، توفير الطاقة | الغشاء ينتفخ ويتسرب بسهولة |

| تقنيات | نظرية | المزايا | العيوب |

| طريقة نقل بخار المواد الكيميائية | اختلافات في السلوك الديناميكي الحراري للمركبات الغازية لعناصر الأرض النادرة، فصل العناصر النادرة عن طريق نقل الغاز الحامل | عملية بسيطة، تلوث منخفض | مستهلك للوقت |

| طريقة الأكسدة والاختزال | تتغير حالة التكافؤ لعناصر الأرض النادرة بواسطة الكيمياء الكهربائية، ثم يتم فصلها بناءً على اختلاف الخصائص. | عملية بسيطة، معدل فصل مرتفع | عناصر الأرض النادرة المتغيرة فقط |

| الاستخراج والترسيب | الاستخراج الكمي للأيونات الأرضية النادرة باستخدام الراسب لاستخراج الراسبات | جزيئات هطول كبيرة، معدلات تحميل وتفاعل عالية، معدلات استخراج عالية | صعوبة في تخليق عوامل الاستخراج والترسيب |

| الطريقة الميكروبيولوجية | فصل العناصر الأرضية النادرة عن طريق التبادل، الأكسدة، الاختزال أو تعقيد الكائنات الدقيقة مع أيونات العناصر الأرضية النادرة | امتصاص سريع، انتقائية عالية، لا تلوث | معدل التسرب المنخفض، تطبيق عملي أقل، الكائنات الحية الدقيقة تعتمد على البيئة |

| طريقة استخراج المذيب غير المتوازن | فصل العناصر الأرضية النادرة بسبب معدلات الاستخراج المختلفة | استهلاك منخفض للطاقة، تشغيل بسيط، تأثير فصل جيد | وقت دورة أطول |

يمكن أن يحسن إنتاجية الأرض بطريقة فعالة من حيث التكلفة وصديقة للبيئة. طبق أموه-أنتوي وآخرون (أموه-أنتوي وآخرون 2021) البيوكربون ونفايات الفحم البني (BCW) في أنظمة التربة، مما يدل على أن BCW مع معالجة رقائق الخشب الحيوية زاد من غلة المحاصيل بنسبة لا تقل عن

يجب عدم إضافة CBSWs وغيرها من النفايات الصلبة ذات المخاطر البيئية مباشرة إلى التربة دون معالجة مسبقة. يُوصى بإجراء معالجة أولية للملوثات السامة والضارة في CBSWs لمنع التلوث المحتمل بالمعادن الثقيلة الناتج عن إضافة CBSWs متعددة المصادر إلى التربة.

5.2 إنتاج الأسمدة

قد تم استخدامه على نطاق واسع في الزراعة لتحسين الخصائص الميكانيكية للمحاصيل وزيادة العائد.

5.3 تكوين المبيدات

6 الاستنتاجات

مشهد إمدادات الطاقة ومتوافق مع استراتيجية “الكربون المزدوج”. تقدم هذه الورقة نظرة عامة على الاستخدام الشامل لمياه الصرف الصحي المعالجة، مع التركيز على الحاجة إلى تعزيز البحث بينما يتم تعزيز تكنولوجيا استغلال الموارد من النفايات الصلبة. بالإضافة إلى ذلك، يتم تسليط الضوء على تطبيق وتعزيز هذه التكنولوجيا، فضلاً عن الوسائل لتحسين كفاءة وفعالية معالجة النفايات الصلبة، وزيادة جهود معالجة النفايات الصلبة والدخل الاقتصادي. لمعالجة هيكل الطاقة في الصين، والذي يُشار إليه غالبًا بتبادل “الاثنين

(1) يتم استخدام CBSWs على نطاق واسع في صناعة مواد البناء، وتحسين التربة الزراعية ومجالات أخرى. ومع ذلك، فإن معدل استخدامها في اتجاهات ذات قيمة عالية أخرى مثل استخراج المعادن، والمواد الجديدة، والتحفيز منخفض. تتضمن عملية استخدام نفايات الفحم الصلبة تكاليف عالية وتتطلب دعمًا تقنيًا أكثر كفاءة. لذلك، هناك حاجة ملحة لتكثيف البحث في تطبيق هذه التكنولوجيا. يجب بذل الجهود لتبسيط إعداد مواد CBSWs الوظيفية. الاعتماد فقط على طريقة استخدام واحدة لن يكون كافيًا لاستيعاب كميات كبيرة من CBSWs عبر المنطقة في فترة زمنية قصيرة. لذلك، من الضروري استكشاف وإقامة نموذج ربط متعدد الصناعات واستخدام تعاوني لـ CBSWs يتناسب مع الظروف المحلية. إن توضيح الآليات التآزرية بين النفايات الصلبة المتعددة وتحديد النسب المثلى لمختلف التطبيقات أمر أساسي لتحقيق استخدام عالي الحجم ومزايا أداء تكاملية.

(2) تختلف خصائص CBSWs بشكل كبير من منطقة إلى أخرى، لذا يمكن بناء قاعدة بيانات وفقًا لذلك. في الوقت نفسه، يمكن تطوير منصة لإدارة البيانات الضخمة وتطبيقها للاستفادة من CBSWs. استنادًا إلى التوزيع الجغرافي لـ CBSWs، يجب تنسيق علاقة التنمية بين الأماكن المختلفة، وتوجيه التكنولوجيا ورأس المال إلى منطقة الإنتاج، وتقليل تكاليف النقل، ودفع التنمية الاقتصادية الإقليمية. بالإضافة إلى ذلك، استكشاف طريقة الاستخدام المشترك لـ CBSWs وغيرها من النفايات المحلية، واستغلال التأثير التآزري لأنواع النفايات المختلفة، وتحقيق الاستخدام الشامل لمختلف النفايات.

(3) وضع معايير ومواصفات للعملية بأكملها، بدءًا من اختيار المواد الخام للنفايات الصلبة، والإنتاج، والتصنيف، والتخزين، وصولًا إلى التطبيق. إنها فكرة تقليل توليد النفايات الصلبة القابلة لإعادة التدوير أو تقليل جزء من استهلاك الطاقة من المصدر، وإعادة تدويرها قدر الإمكان، وتطوير مواد ذات خصائص عالية القيمة للنفايات الصلبة القابلة لإعادة التدوير. في المستقبل، سيتم دراسة مواد النفايات الصلبة القابلة لإعادة التدوير ذات القيمة المضافة العالية التي تأخذ في الاعتبار التكلفة والأداء بشكل أعمق، ودفعها تدريجيًا إلى الاختبارات الصناعية.

الإعلانات

References

Ai G, Wang JC, Deng ZX, Shang RY, Chen H (2022) Effect of coal gasification residue with flat mushroom bran application on the number of soil microbial taxa in coal mining areas. Hubei Agric Sci 61:14-18. https://doi.org/10.14088/j.cnki.issn0439-8114. 2022.22.002

and agricultural applications. Water Air Soil Pollut 232:106. https://doi.org/10.1007/s11270-021-05044-z

Bi S (2023) Development and analysis on 2022 titanium dioxide industry in China. Iron Steel Vanadium Titanium 44:1-3. https:// doi.org/10.7513/j.issn.1004-7638.2023.01.001

Bu XN, Ilhwan P, Ugur U (2023) Editorial: advanced green and sustainable chemical and physical technologies for resources recycling of solid wastes. Front Chem 11:1146404. https://doi. org/10.3389/FCHEM.2023.1146404

Chai L, Yue T, Yan ZH, Liu Q, Xiong YS (2023) Research progress on resource utilization of fly ash. China Resour Compr Util 41:93-98. https://doi.org/10.3969/j.issn.1008-9500.2023.02.024

Chang JW, Du GJ, Du JL, Shi XI (2022) Current situation of the comprehensive utilization of coal gangue in china and the related problems and recommendations. China Environ Prot Ind 08:13-17

Chen Q (2012) Preparation of ceramic glazed tiles with cinder. South China University of Technology, Guangzhou

Chen Q (2015) Microstructural analysis of cinder based ceramics. Sci Technol Visio. https://doi.org/10.19694/j.cnki.issn2095-2457. 2015.27.212

Chen Y (2023) Radioactive risk monitoring and analysis of fly ash for wall materials in Guizhou province. China High-Tech 2:8182+88. https://doi.org/10.13535/j.cnki.10-1507/n.2023.12.30

Chen DH, Li C, Zhang ZG (2022) Study on performance optimization of gasification slag based paste filling materials in Ningdong mining area. Coal Geol Explor 50:41-50. https://doi.org/10. 12363/issn.1001-1986.22.05.0385

Chen Z, Zhang ZM, Gui LZ, Sun K, Duan HB, Hu JP, Liang S, Yang JK (2024) Optimization of the the synthesis conditions of zeolite adsorbents derived from fly ash and study on their adsorption performance on benzene. Energy Environ Prot. https://doi.org/ 10.20078/j.eep. 20240701

Cheng JW, Ren WG, Wang JC, Han LN, Chang LP, Bao WR (2019) Extraction of lithium from coal gangue by manganese ion sieve adsorption. Chem Ind Eng Prog 38:3589-3595. https://doi.org/ 10.16085/j.issn.1000-6613.2019-0155

Cheng G, Li YL, Cao YJ, Zhang ZG (2023a) A novel method for the desulfurization of medium-high sulfur coking coal. Fuel 335:126988. https://doi.org/10.1016/j.fuel.2022.126988

Cheng G, Li YL, Zhang MN, Lau EV (2023b) Improving micro-fine mineral flotation via micro/nano technologies. Sep Sci Technol 58:520-537. https://doi.org/10.1080/01496395.2022.2140293

Cheng Y, Zhu HJ, Zhang SJ, Wu HY, Cong JJ, Luo YQ (2023c) Experimental study on preparation of dry-mixed mortar from coal gangue. Coatings 13:518. https://doi.org/10.3390/coatings13 030518

Cheng G, Zhang MN, Lu Y, Zhang HJ, Lau EV (2024) New insights for improving low-rank coal flotation performance via emulsified waste fried oil collector. Fuel 357:129925. https://doi.org/10. 1016/j.fuel.2023.129925

Chi S, Shang BY, Zhang YH, Zhao XS (2023) Preparation of poly aluminum ferric silicate flocculant flocculant from coal gangue for treatment of fluorine chemical wastewaterr. Environm Prot Chem Ind. https://kns.cnki.net/kcms/detail/11.2215.X.20230516. 1843.006.html

Daniyar S, Seon SC, Saken S, Islam O, Zhang D, Ryeol KJ (2022) Preliminary investigation of geopolymer mixture using GGBFS and off-ASTM class F fly ash. Mater Sci Forum 1053:309-314. https://doi.org/10.4028/p-mx9n06

Dhadse S (2024) Utilization of fly ash in agriculture: perspectives and challenges. J Mater Environ Sci 15(7):1038-1050

Dong LP, Xue ZH, Gao F, Yang CY, Li HP, Bao WR, Wang JC, Fan PP (2024) Research on extraction of carbon from coal gasification fine slag using hydrophobic-hydrophilic separation: efficient separation, molecular dynamics simulation, and model optimization. Fuel 365(131180):0016-2361. https://doi.org/10. 1016/j.fuel.2024.131180

Dou ZS, Wei L, Wang M, Wang C, Xl J, Men GY, Li RJ (2024) Feasibility study on using coal gasification slag as substitute for blast furnace slag to prepare super sulphated cement. Bull Chin Ceram Soc 43(08):2952-2960. https://doi.org/10.16552/j.cnki. issn1001-1625.2024.08.009

Du SL, Dong YC, Guo FQ, Tian BL, Mao ST, Qian L, Xin CY (2021) Preparation of high-activity coal char-based catalysts from high metals containing coal gangue and lignite for catalytic decomposition of biomass tar. Int J Hydrogen Energy 46:1413814147. https://doi.org/10.1016/j.ijhydene.2021.01.179

Du YZ, Liu YL, Shen W, Bai Y, Ma H, Tang S, Yao XY, Hao GP (2023) The basic physcial and chemical properties of coal gangue in some typical areas of Shanxi Province. Coal Process Compr Util 285:80-83. https://doi.org/10.16200/j.cnki.112627/td.2023.04.019

Duan YW, Wang PG, Wang Z, Fang T, Dong AZ, Wang A, Lin W, Shi JL, Huang ZL, Hu XY, Li GX (2016) Present research status on extracting gallium from fly ash. Anhui Chem Ind 42:12-14. https://doi.org/10.3969/j.issn.1008-553X.2016.01. 001

Environment-Environmental Protection (2020) Brawijaya university researchers yield new study findings on environmental protection (the possible use of coal fly ash and phosphate-solubilizing fungi for improving the availability of P and plant growth in acid soil). Ecology Environment & Conservation, 42

Estevam ST, de Aquino TF, da Silva TD, da Cruz R, Bonetti B, Riella HG, Soares C (2021) Synthesis of K-merlinoite zeolite from coal fly ash for fertilizer application. Braz J Chem Eng 39:631-643. https://doi.org/10.1007/s43153-021-00172-9

Fan HG, Sun C, Zhao ZT, Han JH (2021) Adsorption properties of zeolite molecular sieves prepared from fly ash. J Jilin Normal Univ (Natural Science Edition) 42:7-10. https://doi.org/10. 16862/j.cnki.ISSN674-3873.2021.01.002

Fan QY, Zhang CY, Geng YQ, Han XN, Chen L (2022) Effects of fly ash application on the properties of coal gangue matrix and plant growth. Sci Soil Water Conserv 20(5):85-92

Fan XP, Liu J, Kang Z, Dong XG (2023) Strategic thinking of comprehensive utilization of coal gangue and ecological restoration of mines. Environ Sanit Eng 31(01):8-15. https:// doi.org/10.19841/j.cnki.hjwsgc.2023.01.002

Feng PF (2020) Progress and development of high value utilization for coal fly ash from power plant. China Resour Compr Util

Figiela B, Korniejenko K, Bulut A, Şahin B, Azizağaoğlu G, Pławecka K, Kozub B (2023) Influence of the size of milled coal gangue particles on the mechanical properties of geopolymers. Mater Proc 13:4. https://doi.org/10.3390/materproc2023013004

Fu Y, Han JM (2023) Methodological breakthrough in the development of thematic publishing in the new era-academic interpretation based on the spirit of the party’s twenty congresses. Science Technol Publ 46:113-121. https://doi.org/10.16510/j.cnki.kjycb. 20230626.007

Gao X (2022) Research on the preparation of high performance ceramic pellets by self-sintering of coal gasification fine slag. Ningxia Univ. https://doi.org/10.27257/d.cnki.gnxhc.2022.001456

Gao JM, Du ZY, Guo YX, Cheng FQ (2021) Progress and prospect of research on comprehensive utilization of coal fly ash for preparation of mullite-based materials. Clean Coal Technol 27:36-47. https://doi.org/10.13226/j.issn.1006-6772.SW201 22901

Gao M, Li MY, Wang JH, Yang PF, Xu MG (2024) Effect of fly ash on properties and hydration of calcium sulphoaluminate cementbased materials with high water content. Rev Adv Mater Sci 63(1):45. https://doi.org/10.1515/RAMS-2024-0046

Gu JR, Liu XM, Zhang ZQ (2023) Road base materials prepared by multi-industrial solid wastes in China: a review. Constr Build Mater 373:130860. https://doi.org/10.1016/j.conbuildmat.2023. 130860

Guo L, Yang YL, Wang HX, Wang YL, Xu YH (2022a) Preparation of porous material with coal gasification slag and its application in treatment of phenol-containing semi-coke wastewater. Coal Chem Ind 50:56-60. https://doi.org/10.19889/j.cnki. 10059598. 2022.05.014

Guo WC, Zhu XB, Zhang ZG, Li W, Zhang CX (2023) Experimental study on extraction aluminum from coal gangue by roasting activation-acid leaching. Coal Conver. https://kns.cnki.net/kcms/ detail/14.1163.TQ.20230322.1551.002.html

Han HJ, Fu BY, Chen FX, Huang SS, Gao YQ, Huang JB, Li JL (2022a) Research progress on extraction of gallium from fly ash. Guangdong Chem Ind 49:79-81

Han HJ, Huang SS, Fu B, Gao YQ, Chen FX, Li JL (2022) Research progress of lithium extraction from fly ash. Modern Chem Res 16-18

He F, Yin XP, Li YW, Wang SR, Dang ZX (2022a) Research progress in stabilized remediation of contaminated soil by solid waste. Modern Chem Res 24:6-9

He ZQ, Ju F, Ning P, Xiao M, Wang TF, Wang D (2022b) Acoustic emission investigation of coal gangue cementitious composites under effects on fiber type. Case Stud Constr Mater 17:e01567. https://doi.org/10.1016/j.cscm.2022.e01567

He XM, Duan XC, Guo W (2023a) Research status and prospect of preparing building materials from coal gangue. Ceram 448:1518. https://doi.org/10.19397/j.cnki.ceramics.2023.02.044

https://www.energyinst.org/statistical-review

Hu D, Fang M, Zhang Q, Jin WQ, Tian Q, Chang X (2020) The method and research progress on the preparation of silica from solid waste. China Resour Compr Util 38:107-109. https://doi.org/ 10.3969/j.issn.1008-9500.2020.10.028

Huang CM (2023) Experimental study on influence of fly ash recycled concrete on mechanical propertie. Brick-Tile. https://doi.org/10. 16001/j.cnki.1001-6945.2023.03.035

Huang MM, Li HX, Liu ZB (2017) Research progress on gallium extraction from different secondary resources. Nonferrous Met Sci Eng 8:21-28. https://doi.org/10.13264/j.cnki.ysjskx.2017. 01.004

Huang QZ, Shi L, He LQ (2021b) Study and application on efficient resource utilization of coal fly ash in agriculture. Non-Metall Mines 44:12-14+18

Jiang YJ (2022a) Study on preparation and performance of mullite porous ceramics from coal gangue. Anhui Univ Sci Technol. https://doi.org/10.26918/d.cnki.ghngc.2022.000463

Jiang XY (2022b) Preparation of hierarchical molecular sieves based on coal gangue and their ad/desorption performance of VOCs. Guangxi Univ. https://doi.org/10.27034/d.cnki.ggxiu.2022. 002489

Jin SX, Zhao ZH, Jiang SF, Sun J, Pan HB, Jiang L (2021) Comparison and summary of relevant standards for comprehensive utilization of fly ash at home and abroad. IOP Conf Ser Earth Environ Sci 621:012006. https://doi.org/10.1088/1755-1315/621/1/012006

Kaman S, Arun K, Alok SK, Ankita A (2023) Fly ash and TiO

Kong DS, Lu XY, Fan JX, Li L (2013) Research progress on the preparation of silica from coal series solid wastes. Yunnan Chem Technol 40:32-34. https://doi.org/10.3969/j.issn.1004-275X. 2013.03.008

Li CJ (2013) Gallium production status and prospect in China. Light Met. https://doi.org/10.13662/j.cnki.qjs.2013.08.009

Li J (2022) Study on superfine fly ash and Metakaolin permeable concrete. Jiangxi Univ Sci Technol. https://doi.org/10.27176/d. cnki.gnfyc.2022.000203

Li Y, Xia JP, Liu HL, Luo ZQ, Yang J (2017) Extraction of gallium from coal gangue pickle liquor based on response surface methodology. Bull Chin Ceram Soc 36:953-959. https://doi.org/ 10.16552/j.cnki.issn1001-1625.2017.03.034

Li HY, Zhang JQ, Chen JB, Chen WH, Zhao Y, Lin MZ, L1 L, Zhang X, Dai XD (2021a) Global energy transition faces challenges in 2021-based on the bp statistical review of world energy (2022).

Li YJ, Yan RZ, Wang JC, Han DX, Fan PP (2022a) Preparation of cement-based composite materials by using decarbonized coal gasification slag. Clean Coal Technol 28(02):160-168. https:// doi.org/10.13226/j.issn.1006-6772.21080701

Li YL, Cheng G, Zhang MN, Cao YJ, Lau EV (2022b) Advances in depressants used for pyrite flotation separation from coal/ minerals. Int J Coal Sci Technol 9:54. https://doi.org/10.1007/ s40789-022-00526-9

Li GH, Li M, Zhang X, Cao PX, Jiang H, Luo J, Jiang T (2022c) Hydrothermal synthesis of zeolites-calcium silicate hydrate composite from coal fly ash with co-activation of

Li HW, Yan KZ, Wen CL, Liu DD, Guo YX, Zhang YY (2022d) Preparation of activated carbon-mesoporous silica composites from coal gangue and phase transformation during its preparation. Coal Sci Technol 45:789. https://doi.org/10.13199/j. cnki.cst.2022-1211

Li N, Wang JM, Zhang X, OuYang SL (2023a) Research progress on the development of high-value-added using coal gasification slag. Mater Rep 37(23):94-105

Li Q, Dong Y, Jow J, Liang WB, Ji HW (2023b) Fundamental characteristics and application of coal gasification slag. New Build Mater 50:33-36+40. https://doi.org/10.4172/2469-9764. 1000128

Li HW, Chen HY, Wei MW, Wang R, Lei NZ, Wang Q (2023d) Design and preparation of double-layer iron ore tailings cement-based electromagnetic wave absorbing materials containing carbon black and steel fiber. Constr Build Mater 364:129972. https://doi.org/10.1016/j.conbuildmat.2022. 129972

Li PX, Teng Y, Zhang K (2023e) Condition optimization of NaX zeolite synthesized with fly ash. Appl Chem Ind. https://doi.org/ 10.16581/j.cnki.issn1671-3206.20230413.001

Li Y, Wang JM, Zhang X, OuYang SL (2023) Research progress on the development of high-value-added materials by using coal gasification slag. Mater Rep. https://kns.cnki.net/kcms/detail// 50.1078.TB.20230207.1238.007.html

Lin LH, Li CS, Yan YK, Bai WS, Liu LR, Zhang JS (2023) Research on the microwave absorption mechanism of pyrolytic carbon foam materials. Mater Rep. https://kns.cnki.net/kcms/detail/50. 1078.TB.20230407.1842.041.html

Liu LL (2023a) Fossil energy share still up to

Liu S (2023b) Research on the harm of coal mine solid waste and environmental protection treatment technology. Shanxi Chem Ind 43:228-230. https://doi.org/10.16525/j.cnki.cn14-1109/tq. 2023.01.092

Liu JW, Mwamulima T, Wang YM, Fang Y, Song SX, Peng CS (2017) Removal of Pb (II) and Cr (VI) from aqueous solutions using the fly ash-based adsorbent material-supported zero-valent iron. J Mol Liq 243:205-211. https://doi.org/10.1016/j.molliq. 2017. 08.004

Liu MR, Yang YD, Yang SJ, Liu XL, Zhang B, Wang H, Liu XY, Tang G (2021a) Study on status of comprehensive utilization of fly ash. Ind Miner Process 50:45-48. https://doi.org/10.16283/j. cnki.hgkwyjg.2021.04.010

Liu Y, Xiao WH, He TS, Tian CA, Wang C (2021b) Study on the preparation of mullite materials by resourcefulness of acidwashed fly ash. Guangdong Build Mater 37:17-20. https://doi. org/10.3969/j.issn.1009-4806.2021.10.008

Liu YL, Li Q, Chen ZF, Zhao J, Zhao Y, Sun LP (2022) Research progress characteristics analysis and comprehensive utilization of coal gasification slag. Coal Sci Technol 50(11):251-257

Liu DR, Xu LJ, Li SC, Cao K, Tu Y, Li WQ, Liu QL (2023) Research progress of recovery of strategic metal lithium from fly ash. Inorg Chem Ind 55:56-63. https://doi.org/10.19964/j.issn.1006-4990. 2022-0471

Liu XH, Zhang J, Li Q, Liang WD (2024) Preparation of technosol based on coal gangue and its impact on plant growth in coal mining area. J Clean Prod 467:142998-142998. https://doi.org/ 10.1016/J.JCLEPRO.2024. 142998

Lu CY (2019) Effects of coal gasification slag on antibiotic resistance genes during agricultural waste composting. Northwest A&F University, Xianyang

Lu XF, Wang L, Wang XD, Niu XK (2008) Research progress in gallium recovery technology. Nonferrous Met 60:105-108+114

Lu M, Xiong ZH, Fang KJ, Li X, Li JQ, Li T (2020) Steam reforming of toluene over nickel catalysts supported on coal gangue ash. Renew Energy 160:385-395. https://doi.org/10.1016/j.renene. 2020.06.012

Luo J, Liao R (2022) Preparation of zeolite A and silica from fly ash by alkali fusion-desilication. Environ Prot Chem Indus 42:732737. https://doi.org/10.3969/j.issn.1006-1878.2022.06.013

Lyashenko VI, Dyatchin VZ, Lisovoy IA (2018) Increase of environmental safety of mining production on the basis of waste utilization of extraction and processing of ore raw materials. Ecol Ind Russia 22:4-10. https://doi.org/10.18412/ 1816-0395-2018-4-4-10

Ma Y (2022) Study on preparation and properties of cement-based fly ash foam concrete. Ningxia Univ. https://doi.org/10. 27257/d.cnki.gnxhc.2022.001887

Mao HJ, Wang FL, Zhu XL, Chen XY, Li W, Zhang WJ (2022) Design of a

Modi P, Jamal A, Singh N (2022) Coal characterization and occurrence of rare earth elements in coal and coal-ash of Sohagpur coalfield, Madhya Pradesh, India. Int J Coal Prep Util 42:2976-2989. https://doi.org/10.1080/19392699.2021. 1923489

Modi P, Jamal A, Varshney R, Rahi IC (2023) Occurrence, mobility, leaching, and recovery of rare earth elements and trace elements in Sohagpur coalfield, Madhya Pradesh, India. Int J Coal Prep Util 43:103-118. https://doi.org/10.1080/19392 699.2021.2014823

Nan YC, Yang YG, Wang ZQ, Zhou Y, Su QM (2023) Effects of coal gangue on soil property and plant growth in mining area. Chin J Appl Ecol 34:1253-1262. https://doi.org/10.13287/j. 1001-9332.202305.028

Ngo I, Ma LQ, Zhai JT, Wang YY (2023) Enhancing fly ash utilization in backfill materials treated with

Pan JH (2021) Study on the enrichment, extraction, and mechanism of occurrence of rare earth elements in coal fly ash. China Univ Min Technol. https://doi.org/10.27623/d.cnki.gzkyu.2021.000060

Peng CH, Lu JS (2012) Preparation and properties of calcium aluminosilicate glass-ceramics from waste glass and fly ash. Trans Mater Heat Treat 33:32-36. https://doi.org/10.13289/j. issn.1009-6264.2012.10.004

Pittayavinai P, Tangchirapat W, Johns J, Nakaramontri Y (2023) Flexible canvas produced from uncured-natural rubber composites filled with high calcium oxide fly ash/cement hybrid filler. Constr Build Mater 368:130438. https://doi.org/10.1016/j. conbuildmat.2023.130438

Qi S, Huang Z, Zhang FM, Didar Y, Liang Q, Liu KF, Lü ZG, Wang SL, Shi SW (2023) Research of peat and fly into substrates and its effects on seedling effects. J Beijing Univ Agric 38:11-17. https://doi.org/10.13473/j.cnki.issn.1002-3186.2023.0203

Qin ZH, Yuan Y, Chen ZS, Li Y, Xia YQ (2024) Combined preparation and application of geopolymer pavement materials from coal slurry-slag powder-fly ash mining solid waste: A case study. Constr Build Mater 441:137510. https://doi.org/10.1016/J. CONBUILDMAT.2024.137510

Rashad AM, Ezzat M, ElNagar AM, El-Nashar MH (2023) Valorization of limestone powder as an additive for fly ash geopolymer cement under the effect of the simulated tidal zone and seawater attack. Constr Build Mater 369:130616. https://doi.org/10.1016/j.conbu ildmat.2023.130616

Rushwaya MJ, Ndlovu S (2017) Purification of coal fly ash leach liquor by solvent extraction: Identification of influential factors using design of experiments. Int J Miner Process 164:11-20. https:// doi.org/10.1016/j.minpro.2017.05.004

Su HF, Lin JF, Chen H, Wang QY (2021) Production of a novel slowrelease coal fly ash microbial fertilizer for restoration of mine vegetation. Waste Manag 124:185-194. https://doi.org/10.1016/j. wasman.2021.02.007

Su SF, Tahir MH, Cheng XX, Zhang JS (2024) Modification and resource utilization of coal gasification slag-based material: a review. J Environ Chem Eng 12(2):112112. https://doi.org/10. 1016/j.jece.2024.112112

Sun DS, Guan YM, Liu KW, Wang AG, Wang SC (2016) Preparation and properties of glass-ceramics based on coal gangue by sintering. Mater Rep 30:134-137

Sun WB, Guo BB, Luo CL, Wang ZL, Lu Y (2017) Research on experiment of the backfill material with coal gasification wastes used as aggregate. China Min 26:166-168

Tang S, Zhang XQ, Jiang LP, Zhong XJ, Xiao L, Wei YF (2024) Preparation of coal gangue/BiVO4 composite photocatalyst and its degradation of xanthate wastewatere. Acta Mater Compos Sin. https://doi.org/10.13801/j.cnki.fhclxb.20230505.001

Tang FJ, Bi HM, Gao JL, Feng YX (2006) Current research on the resource-oriented utilization of cinder. J Heilongjiang Bayi Agric Univ 76-79

Ukwattage NL, Lakmalie UV, Gamage RP (2021) Soil and plant growth response and trace elements accumulation in sweet corn and snow pea grown under fresh and carbonated coal fly ash amendment. Agron J 113(4):3147-3158. https://doi.org/10.1002/ AGJ2.20711

United Nations Environment Programme (2024) Global waste management outlook 2024: beyond an age of waste, turning rubbish into a resource

Varshney A, Dahiya P, Mohan S (2022) Growth, biochemical, and antioxidant response of pot marigold (Calendula officinalis L .) grown in fly ash amended soil. Int J Phytorem 25:115-124. https://doi.org/10.1080/15226514.2022.2063794

Wang S (2016) Fabrication of coal-based carbon foam composites for microwave absorption. Dalian University of Technology, Dalian

Wang JL (2022a) Preparation, modification of coal gasified ash residue activated carbon. Nanjing Univ Inf Sci Technol. https://doi.org/ 10.27248/d.cnki.gnjqc.2022.001033

Wang WJ (2022d) In situ synthesis of connected porous foam concrete block with fly ash and synergistic removal of heavy metals and sulfate in acid mine wasrewater. Nanchang Univ. https://doi.org/ 10.27232/d.cnki.gnchu.2022.002815

Wang ZH, Ma GX, Lu J, Liao WP, Li DQ (2002) Separation of heavy rare earth elements with extraction resin containing 1-hexyl-4ethyloctyl isopropylphosphonic acid. Hydrometallurgy 66:95-99. https://doi.org/10.1016/S0304-386X(02)00109-3

Wang H, Chen J, Liu YG, Huang ZH, Fang MH (2015) In-situ synthesis of (

Wang R, Wang JS, Song QC (2022b) Optimized preparation of porous coal gangue-based geopolymer and quantitative analysis of pore structure. Buildings 12:2079. https://doi.org/10.3390/buildings1 2122079

Wang H, Chen ZW, Meng Z, Liu LL, Wang XD, Xing Y (2023a) Integrated utilization of coal gangue for synthesis of

Wang Q, Qi Y, Wang K, Yang SQ, Miao Y, Gao F (2023b) Preparation of fly ash-based no-sintered high-strength filter and its removal of

Wang P, Fu ZY, Wang F, Sun JK, Lu YH, Huang ZB, Zhang L, Dong Z, Gao TW (2024) Research progress of the application of coalbased solid waste for soil remediation. Clean Coal Technol 2024:1-16

Wang JZ, Wang MH, Gong ZY, Chen C, Wang YP (2024a) Extraction of iron from coal gangue by preheating, carbon thermal reduction and magnetic separation. Mater Res Appl 45:1-6. https://doi.org/ 10.20038/j.cnki.mra.2024.000013

Wei JX, Wang YS (2010) Use of the CWM prepared with mine slurry as fuel of ceramic kiln. Hydraulic Coal Min Pipeline Transp. https://doi.org/10.14187/j.cnki.cn13-1185/tn.2010.02.002

Wu FL, Li SC (2023) Research progress of aluminum, gallium and lithium recovery technologies for fly ash. China Nonferrous Metall 52:116-125. https://doi.org/10.19612/j.cnki.cn11-5066/ tf.2023.02.015

Wu DX, Luo L, Jia YJ, Cheng W (2019) Synthesis of a-zeolite from coal fly ash by Alkali fusion-hydrothermal process and its adsorption research. Bull Chin Ceram Soc 38(6):1873-1877. https://doi.org/10.16552/j.cnki.issn1001-1625.2019.06.039

Wu CL, Wang WL, Wang XJ, Li JW (2023a) Research status and innovatiove utilization strategy of coal gangue resource in building material field. Energy Environ Prot 37:167-177. https:// doi.org/10.20078/j.eep. 20230112

Wu GL, Wu HJ, Jia ZR (2023b) Editorial for special issue on electromagnetic wave absorbing materials. Int J Miner Metall Mater 30:401-404. https://doi.org/10.1007/s12613-022-2578-1

Wu H, Chen CW, Song WM, Hou WQ (2024) High-capacity utilization of coal gangue as supplementary cementitious material, geopolymer, and aggregate: a review. Constr Build Mater 435:136857. https://doi.org/10.1016/j.conbuildmat.2024.136857

Xia JY (2014) Study on the treatment of pesticides wastewater by fenton reagent. Nanjing Agricultural University, Nanjing

Xiang J, Li JH, Wang GF, Xue QY, He JQ, Liu SJ, Hu QY (2023) Extraction of silica from fly ash and modification by silane coupling agent. Bull Chin Ceram Soc 42:989-1000. https://doi. org/10.16552/j.cnki.issn1001-1625.2023.03.019

Xie HW, Pan FY, Liu ZQ, Li ZZ, Liu XX (2023) Strengh mechanism of cement cementitious hardening products affected by coal gasification slag or fly. J chang’an Univ (Natural Science Edition) 43:26-34. https://doi.org/10.19721/j.cnki.1671-8879.2023.02. 003

Xing JK, Qi DE, Qin SJ, Kang S, Wang Q, Li SY (2023) Research progress on high-value utilization of valuable elements in fly ash. Modern Chem Ind 43:39-43+49. https://doi.org/10.16606/j.cnki. issn0253-4320.2023.07.008

Xu RB (2023) Long-term risk assessment of fly ash-filled materials. Inner Mongolia Univ Sci Technol. https://doi.org/10.27724/d. cnki.gnmgk.2023.000906

Xu P, Zuo TL (2018) Comprehensive utilization of high alumina coal fly ash under the recyclable economy model. Ind Chem 4:1000128. https://doi.org/10.4172/2469-9764.1000128

Xu GL, Sun CM, Sun Y, Liao H (2013) A new comprehensive utilization method for coal gangue: preparing alitesulphoaluminate cement. Adv Mater Res 652-654:1527-1532. https://doi.org/10.4028/www.scientific.net/AMR.652-654.1527

Xu LJ, Liu DP, Zhang YF, Chi JZ, Chen D (2022) Research progress of lithium extraction technology from fly ash. Rare Met Cem Carbides 50:12-16. https://doi.org/10.19990/j.issn.1004-0536. 2022.04.012.05

Yan PX, Zou HH, Ke SJ, Cheng L (2023b) Study on foaming process of sepiolite and cinder synergistically filling ceramics. China Ceram 59:56-59. https://doi.org/10.16521/j.cnki.issn.1001-9642.2023. 05.009

Yin DY, Xue XR (2023) Research progress on resource reuse of environmental protection building materials prepared from coal gangue. Guangzhou Chem Ind 51:46-48

Yu XT, Tian Y, Liu CT, Zhou SX, Chen Q, Wang Q, Pang SF, Su Q, Wang YB (2023) Carbon catalysts and their applications polysaccharide. Anhui Chem Ind 49:8-12+15. https://doi.org/ 10.3969/j.issn.1008-553X.2023.02.002

Zang JK (2022) Experimental study on the leaching of lithium from fly ash of a power plant in Guizhou. Guizhou Univ. https://doi. org/10.27047/d.cnki.ggudu.2022.000820

Zeng L, Sun HJ (2022) Preparation of porous glass ceramics by direct sintering of coal fly ash. J Chengdu Univ (Natural Science Edition) 41:408-413

Zhang YN (2022) Experimental study on the effect of fly ash on the mechanical and durability properties of recycled concrete. Inner Mongolia Univ Sci Technol. https://doi.org/10.27724/d.cnki. gnmgk.2022.000852

Zhang MM, Chen X, Fu XL (2019) A review on the utilization progress of fly ash in the functional materials. Ordnance Mater Sci Eng 42:124-128. https://doi.org/10.14024/j.cnki.1004-244x. 20190 816.002

Zhang DS, Wang YF, Ma MX, Guo XJ, Zhao SQ, Zhang SX, Yang QN (2022) Effect of equal volume replacement of fine aggregate with fly ash on carbonation resistance of concrete. Materials 15:1550. https://doi.org/10.3390/ma15041550

Zhang MN, Cheng G, Lu Y, Cao YJ, Lau EV (2023a) Preparation of long-flame coal flotation collector from waste cooking. Miner Eng 202:108296. https://doi.org/10.1016/j.mineng. 2023.108296

Zhang LH, Jin YR, Cheng FQ (2023b) Resource utilization of coal gasification slag. Chem Ind Eng Prog. https://doi.org/10.16085/j. issn.1000-6613.2022-1845

Zhang CM, Zhang R, Cao Y (2023c) The extraction of valuable rare earth elements from gasification solid residues. Appl Chem Ind 52:63-67. https://doi.org/10.16581/j.cnki.issn1671-3206.20221 123.006

Zhao D, Song SJ, Wu HX (2017) Study on best separation methods of oxide titanium from fly ash in Liupanshui area. Guangzhou Chem Ind 45:80-82

Zhao ZS, Cui L, Guo YX, Cheng FQ (2021) Research progress on extraction and recovery of strategic metal gallium from coal fly ash. CIESC J 72:3239-3251. https://doi.org/10.11949/04381157.20201400

Zhao Y, Li X, Li YY, Bao HY, Xing J, Zhu YZ, Nan J, Xu GR (2022b) Biochar acts as an emerging soil amendment and its potential ecological risks: a review. Energies 16:410. https://doi.org/10. 3390/en16010410

Zhao BH, Zhu YH, Wang C (2023a) Degradation of humic acid via peroxymonosulfate activation by

Zhao GW, Wu T, Ren GZ, Zhu Z, Gao Y, Shi M, Ding SJ, Fan HH (2023b) Reusing waste coal gangue to improve the dispersivity and mechanical properties of dispersive soil. J Clean Prod 404:136993. https://doi.org/10.1016/j.jclepro.2023.136993

Zhu FX, Wang Y (2022) Study on extraction of alumina from high alumina coal ash by one-step acid solution. Adhesion 49:116120. ISSN: 12.3969/j.issn.1001-5922.2022.12.026

Zhu DD, Xue B, Jiang YS, Wei CD (2019) Using chemical experiments and plant uptake to prove the feasibility and stability of coal gasification fine slag as silicon fertilizer. Environ Sci Pollut Res Int 26(6):5925-5933. https://doi.org/10.1007/s11356-018-4013-8

Zhu JF, Li J, Yan L, Shang JF, Wang YQ, Li Q, Wang JY (2021a) Research progress and application prospect of coal gasification slag resource utilization. Clean Coal Technol 27:11-21. https:// doi.org/10.13226/j.issn.1006-6772.21010301

Zhu T, Yuan B, Hao WX, Han YW, Liu S, Liu YT, Song HP (2022) Research progress on

Zong G, Xie YX (2023) Preparation and performance study of fly ash forming adsorbent materials. Appl Chem Ind 52:10151018+1023. https://doi.org/10.16581/j.cnki.issn1671-3206. 20230217.008

utilization and

- Gan Cheng

chenggan464@126.com

College of Chemistry and Chemical Engineering, Henan Polytechnic University, Jiaozuo 454003, China

Institute of Resources and Environmental Engineering, Shanxi University, Taiyuan 030031, China 3 Shanxi Laboratory for Yellow River, Shanxi University, Taiyuan 030031, China4 School of Engineering, Monash University Malaysia, 47500 Subang Jaya, Selangor, Malaysia

DOI: https://doi.org/10.1007/s40789-025-00775-4

Publication Date: 2025-04-19

Towards carbon neutrality: A comprehensive study on the utilization and resource recovery of coal-based solid wastes

© The Author(s) 2025

Abstract

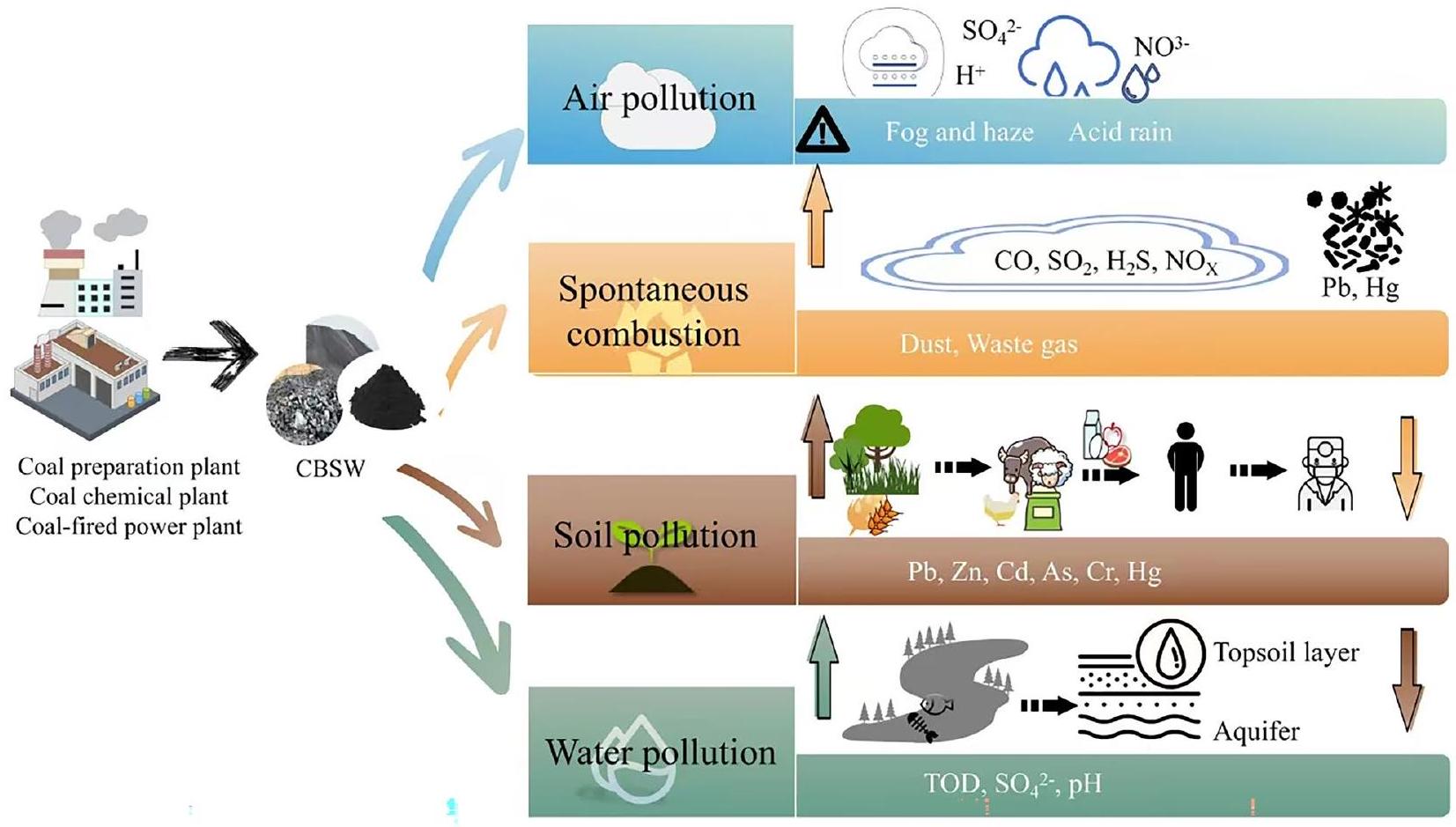

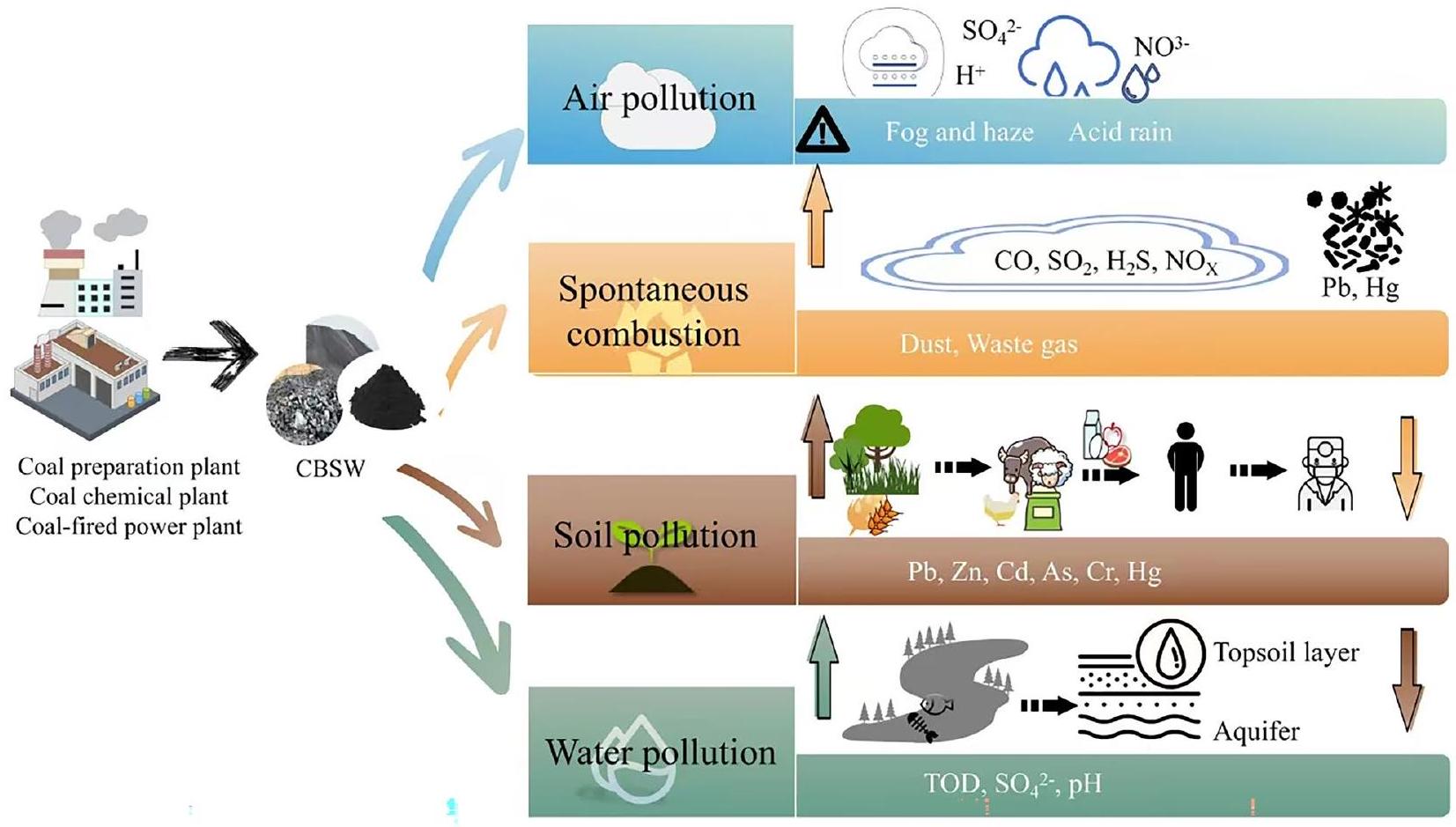

Coal-based soild wastes (CBSWs) are industrial byproducts that can be harmful to the environment. The exploitation and utilization of CBSWs offer societal advantages such as resource conservation, pollution reduction, and cost-effective production. However, environmentally sustainable management remains a worldwide challenge due to the substantial production volume and limited disposal capacity of CBSWs. The physicochemical properties and utilization of CBSWs are summarized, including fly ash, coal gangue and coal gasification slag. It also presents the current global applications status of CBSWs resources and examines market supply and demand. Subsequently, the paper provides an overview of studies on ways to utilise CBSWs, highlighting the primary avenues of CBSWs resource utilization which are mainly from the fields of chemical materials, metallurgy and agriculture. Furthermore, a comparative evaluation of the various methods for CBSWs resource recovery is conducted, outlining their respective advantages and disadvantages. The future development of CBSWs recycling processes is also discussed. The review concludes that while there is a growing need for attention in CBSWs recycling, its utilization will involve a combination of both large-scale treatment and refinement processes. The paper aims to offer references and insights for the effective utilization and environmental protection of CBSWs. Future direction will focus on the collaborative utilization of CBSWs, emphasizing on the combination of large-scale and high-value utilization. In addition, there is a need to establish a comprehensive database based on on-site production practices, explore on-site solutions to reduce transportation costs, and improve physicochemical properties during the production process.

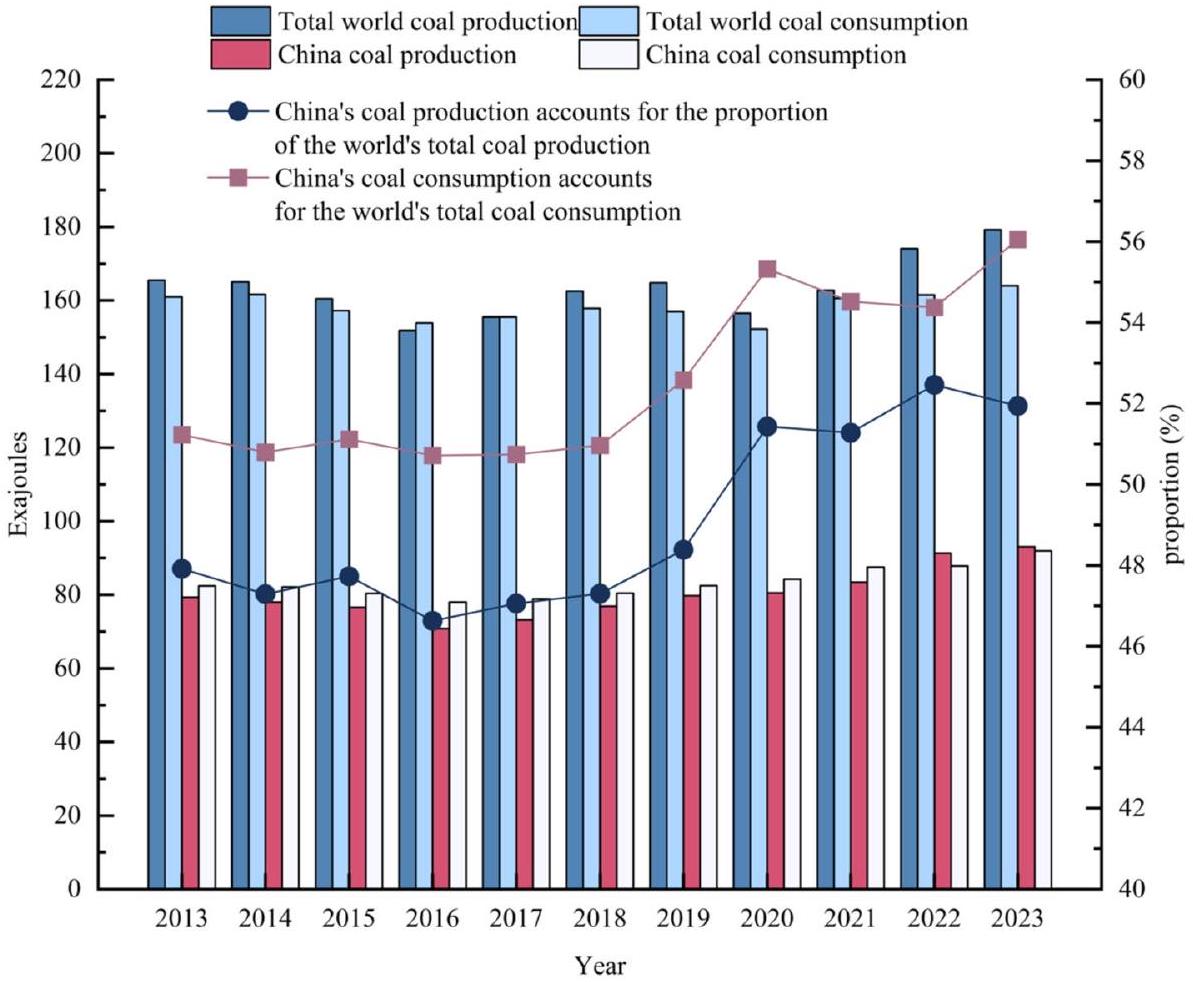

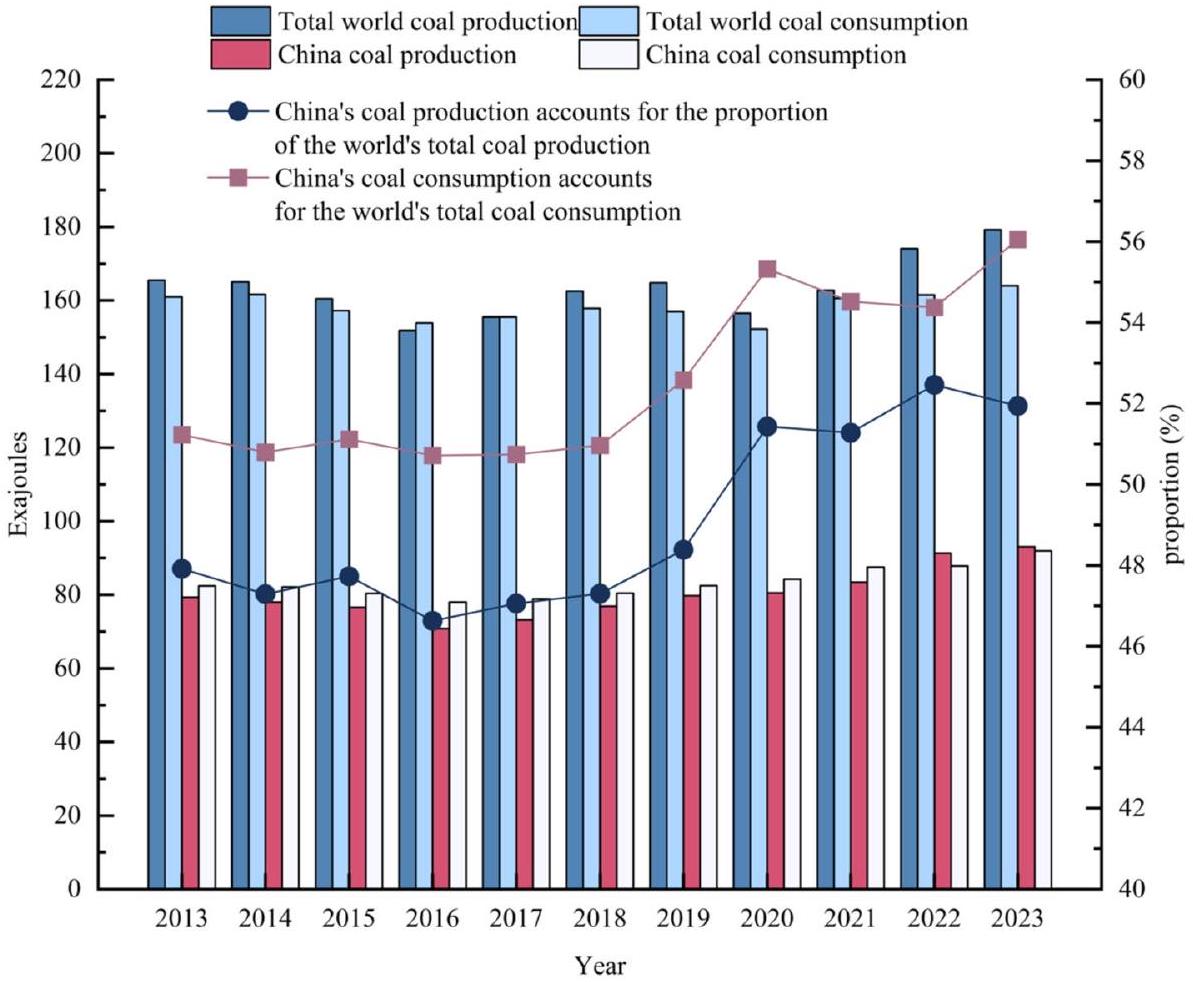

1 Introduction

2 Characteristics of coal-based solid waste

2.1 Coal gangue

accounting for

2.2 Fly ash

utilization rates vary largely among countries, ranging from 99% in Japan to only 11% in Africa and the Middle East (Jin et al. 2021; Xu and Zuo 2018). In 2021, China’s FA production reached 7.9 billion tons (Chen et al. 2024), with an expected increase to 9.25 billion tons by 2024 (Zhang

| Utilization way | Utilization rate of FA (%) | |||

| China | America | Japan | European Union | |

| Building material | 64 | 33.05 | 67.12 | 90.8 |

| Mine filling | 20 | 28.92 | 10.31 | |

| Wastewater treatment | 9 | 23.77 | 22.88 | 9.2 |

| Soil modification | 7 | 14.26 | ||

2.3 Coal gasification slag

majority of CGS is simply dumped or landfilled. In 2019, CGS emissions in China exceeded 35 million tons, with a comprehensive utilization rate of only

| Component/ Content | CG | FA | CGS |

|

|

44.78~61.70 | 33.90~59.70 | 14.86~53.36 |

|

|

15.53~39.05 | 16.50~35.40 | 7.72~16.81 |

|

|

|

1.50 ~ 15.40 | 7.37~41.19 |

| CaO | 0.33~4.14 |

|

6.79~19.04 |

| MgO |

|

|

0.86~2.40 |

|

|

|

|

– |

|

|

– |

|

1.55~3.22 |

|

|

– |

|

– |

| LOL | 13.99~16.30 | 1.20~23.50 | 1.19~52.91 |

| Type | Main composition | Secondary composition | Utilization modes | ||||

| CG |

|

|

Soil amendments, aluminum-based chemical raw materials, silicon-based chemical products and ceramic raw materials, adsorbents, cement, bricks and new wall materials | ||||

| FA |

|

|

Cement, concrete, wall fabrication and functional coatings, soil fertilizer manufacturing, adsorbents, water silicate, road construction and backfilling of coal mining subsidence areas | ||||

| CGS | Amorphous phase | Crystalline phase |

|

||||

| Amorphous aluminosilicate, carbonaceous | Quartz, mullite, galenite and calcite | Gel material |

3 Application of CBSWs in the field of chemical materials

3.1 Building materials

3.1.1 Cement

3.1.2 Concrete

content. In another study, Xiang et al. (2022) investigated the use of FA as a mineral admixture and CGS to replace natural sand in the preparation of FA concrete. Results of this study showed an increase in the degree of concrete compactness with the addition of

3.1.3 Wall materials

rate of the filling material slurry varying with CGS content. As CGA content increased, the dewatering rate of CGS decreased.

3.1.4 Ceramic materials

3.1.5 Glass-ceramics

crystallized at

3.1.6 Geopolymer

3.1.7 Mullite materials

| Mullite materials | Applications |

| Refractory materials | Building materials, metallurgy, petroleum, chemical industry, machinery, ceramics, electric power, aviation, etc |

| Coating materials | Metallurgy, ceramics, aerospace, metallurgy, catalysis, etc |

| Reinforcing materials | Chemical industry, electric power, metallurgy, machinery, etc |

| Abrasion resistant materials | Building materials, chemicals, machinery, etc |

| Filter materials | Water treatment, electric power, chemical industry, machinery, etc |

3.2 Functional materials

3.2.1 Adsorption materials

3.2.2 Electromagnetic wave-absorbing materials

excellent electrical conductivity. The residual carbon contained in CBSWs is not only porous and partially lithified, but possesses a pore structure which allows for multiple reflection and absorption of electromagnetic waves. These advantages highlight its potential as a raw material for wave-absorbing materials (Li et al. 2023c). Lin et al. (2023) prepared pyrolytic carbon foam wave-absorbing materials using a prefabricated body method combined with a pyrolysis process. The study found that pyrolytic carbon foam materials are suitable as wave-absorbing materials within the temperature range of

3.2.3 Zeolite molecular sieves

traditional hydrothermal method. In addition, the use of microwave can also reduce reaction time and temperature, thereby enhancing the crystallisation of the products. Jiang et al. (Jiang 2022b) used alkali hot melt-acid leaching treatment to synthesize ZSM-5 molecular sieves, with optimal conditions as follows: roasting temperature of

3.2.4 Catalysts and catalyst carriers

via the hydrothermal method and results showed that the photocatalytic performance of the loaded

3.2.5 Composites

3.2.6 Silica

| Route of utilisation | Products | Advantages | Disadvantages | References |

| Building materials | Cement | Conducive to the hydration reaction of cement, shortened setting time, improves the compressive and anti-cracking strength | Requires calcination treatment, strict requirements on the amount of loss on burning, harsh reaction conditions | Wang (2022c), Guo et al. (2022b), He et al. (2022b) |

| Concrete | Enhances compressive and cracking strength as well as frost resistance | Requires processing such as crushing, screening and heat treatment | Wang (2022d), Li (2022), Ma (2022) | |

| Wall materials | Thermal insulation, energy saving and waste reduction, increased density and durability | Complex process, high investment, high cost, and in the experimental research stage | Huang (2022) | |

| Ceramic materials | Capitalising on the rich inorganic mineral content of coal waste | Complex process, high cost | Yan et al. (2023b), Chen (2015), Chen (2012), Wei and Wang (2010) | |

| Glass-ceramics | Lower cost and high utilisation | Higher temperatures are required and yield is not stable | Mao et al. (2022), Zeng and Sun (2022), Luo et al. (2022), Sun et al. (2016), Dang and He (2020) | |

| Geopolymer | Simple process, high utilisation | Synthetic geopolymers are less stable and more costly | Wang et al. (2023c), Wang et al. (2022b), Zhao et al. (2022a), Li et al. (2021b), Zhang et al. (2020), Rashad et al. (2023), Lekshmi and Sudhakumar (2022) | |

| Mullite materials | Easy to obtain raw materials, addresses the problem of limited natural mullite, high flexural strength, good corrosion resistance | Requires pre-processing to reduce the glassy phase and to dissolve impurities | Liu et al. (2021b); Wang et al. (2021) | |

| Functional materials | Adsorption materials | Large specific surface area and rich pore structure | Requires calcination process | Liu et al. (2017), Kaman et al. (2023), Abdulsalam et al. (2020) |

| Electromagnetic waveabsorbing materials | Inexpensive, low density | Functionalisation or metallisation is required; there are still relatively narrow absorption bands, low absorption efficiency and poor electromagnetic matching | Zhang et al. (2019) | |

| Zeolite molecular sieves | Simple method for mass production | Reaction conditions need to be strictly controlled and the quality of CBSWs required is high | Zhu et al. (2022), Fan et al. (2021) | |

| Catalysts and catalyst carriers | Sparse and porous, good for preparation of catalysts, good carrier | Technological immaturity | Lu et al. (2020), Du et al. (2022), Du et al. (2021) | |

| Composites | Responding to high material costs | Complex and costly treatment of residues and waste liquids | Pittayavinai et al. (2023) | |

| Silica | Conserve chemical raw materials, reduce costs, alleviate the pressure of coal solid waste on the environment, increase the added value of products, and extend the coal industry chain | Requires the control of mineral properties and activation. conditions for different coal system wastes, and the process is complex and energy-consuming | Kong et al. (2013) |

4 Application of CBSWs in metallurgy

4.1 Aluminium extraction

liquid-solid ratio of

4.2 Gallium extraction

| Methods | Specific processes | Advantages | Disadvantages |

| Alkali method | Pre-desilication-alkali sinteringcalcination | High aluminium extraction rate | High energy consumption, large amount of waste residue, high alkali consumption |

| Acid method | Activation-acid leachingcalcination | Low energy consumption, low amount of waste residue | Serious corrosion of equipment and complicated decontamination process |

| Hydrochemical method | NaOH roasting-water chemistry process | High aluminium extraction rate, low energy consumption, silica residue; easy to decompose | High alkali concentration, poor slurry flowability, and Higher material consumption |

| Vacuum reduction method | Vacuum thermal reduction process | Almost no secondary pollutants, green environmental protection | Still at the laboratory research stage |

| Carbon thermal chlorination | Carbon thermal chlorination process | Almost no secondary pollutants, the process allows the use of chlorine gas as a feedstock in the cycle and the simultaneous extraction of silicon, calcium and titanium | Still at the laboratory research stage |

| Methods | Theory | Advantages | Disadvantages | References |

| Adsorption | Functional groups on the structure of the adsorbent adsorb gallium ions in solution, separating gallium ions from impurities or impurity ions present in solution | High gallium recovery, simple process, no special requirements for industrial production | Adsorbent materials are expensive and costly to produce | Li (2013) |

| Sedimentation | Leverages on the different densities and precipitate under gravity | Simple and convenient, low cost, mature technology | Multiple precipitations are required, which is time-consuming, easily affected by other impurity ions, and the purity of the extracted gallium is low | Duan et al. (2016) |

| Extraction | The difference in solubility or partition coefficient of the target element in two immiscible solvents can be exploited to selectively transfer the target element or impurities | Simple operation, mainly used for the extraction of gallium in acid leach solution | Loss of extractant and contamination of the extracted liquid | Han et al. (2022a), Liao et al. (2017) |

| Ion exchange method | The extraction or removal of certain ions from a solution is accomplished by exchanging ions in a solid ion exchanger with specific ions in a diluted solution | Simple operation, small investment in equipment | The exchange rate is low, the production cycle is long, and a large amount of regeneration waste liquid is generated | Wang and Zhang (2019) |

| Gonzie electrolysis | Gallium is extracted by electrolysis from gallium-containing

|

Gallium can be extracted directly and high purity of metallic gallium can be obtained | High mercury consumption, mercury contamination of the work environment, negative impacts on human health, practical use may be limited | Lu et al. (2008) |

| Emulsion film method | By interfacial reaction between two or more solutions of different compositions that are mutually soluble | Efficient, fast and energy-saving, particularly in the separation of low concentration components | The application of gallium extraction from CBSWs is still in the research stage | Huang et al. (2017) |

4.3 Lithium extraction

4.4 Titanium extraction

| Table 8 Characteristics of various lithium leaching processes | ||||

| Methods | Technological process | Advantages | Disadvantages | Effect on the extraction of the leachate |

| Acidfication method | Direct acid leaching process; Sintering process-acid leaching process | Simple process, low energy consumption and cost | Difficult to obtain high leaching rates for coal pulverised FA with low lithium activity, and only applicable to fluidised bed FA, which requires a long process flow, high energy consumption and cost | Complex composition of acid leach solution, lithium extraction is difficult |

| Alkali method | Pre-desilication-sintering -leaching process | Similar to the traditional Bayer method and this process is relatively mature | Complex composition of acid leach solution, lithium extraction is difficult | Desilication solution, leaching solution impurities are simple, lithium extraction is relatively easy |

| Other methods | Combined acid-base process; Multistep countercurrent continuous cycle alkaline leaching process | Higher leaching rate and lower energy consumption | Still at the stage of small laboratoryscaled pilot studies | The leachate has fewer impurity elements and lithium is easier to extract |

4.5 Rare earth elements extraction

5 Application of CBSWs in agriculture

5.1 Soil amendment

| Techniques | Theory | Advantages | Disadvantages |

| Chemical precipitation | Separation of rare earths according to their solubility in solvents | Simple and easy to operate equipment | High cost, low separation rate, high environmental pollution |

| Ion exchange and adsorption methods | Rare earth elements can be separated by adsorption on the resin and reaction with the extractant in the resin | Good separation efficiency, high purity, low contamination | Long cycle time, low treatment capacity, high cost |

| Extraction chromatography | Separation of rare earth elements due to different partition coefficients in the solid-liquid phase | Simple equipment, good selectivity and high efficiency | High acid consumption, extractant easily dislodged |

| Solvent extraction | Separation of rare earths in the aqueous and organic phases by the action of extractant with different solubility or partition coefficients | Good selectivity, large treatment capacity, high purity, continuous process | High cost, high energy consumption, high toxicity of certain solvents |

| Liquid membrane separation | Extraction and counter-extraction via selectively permeable membranes | High efficiency, simple method, energy saving | Membrane swells and leaks easily |

| Techniques | Theory | Advantages | Disadvantages |

| Chemical vapour phase transport method | Differences in the thermodynamic behaviour of gaseous complexes of rare earth elements, Separation of rare earths by carrier gas transport | Simple process, low pollution | Time-consuming |

| Redox method | The valence state of rare earth elements is changed by electrochemistry, and then separated by the difference in properties | Simple process, high separation rate | Variable rare earth elements only |

| Extraction and precipitation | Extraction-precipitant quantitative extraction of rare earth ions to produce extractant precipitates | Large precipitation particles, high loading and reaction rates, high extraction rates | Difficulty in synthesising extraction-precipitation agents |

| Microbiological method | Separation of rare earths by exchange, oxidation, reduction or complexation of microorganisms with rare earth ions | Fast adsorption, high selectivity, no pollution | Lower leaching rate, less practical application, microorganisms are environmental dependent |

| Non-equilibrium extraction solvent method | Separation of rare earths due to different extraction rates | Low energy consumption, simple operation, good separation effect | Longer cycle time |

could improve land productivity in a cost-effective and environmentally friendly manner. Amoah-Antwi et al. (Amoah-Antwi et al. 2021) applied biochar and brown coal waste (BCW) in soil systems, demonstrating that BCW with wood chip biotreatment increased crop yields by at least

safety, CBSWs and other solid wastes with environmental safety risks should not be directly added to the soil without pre-treatment. It is recommended to conduct preliminary treatment of toxic and harmful pollutants in CBSWs to prevent potential heavy metal pollution caused by the addition of multi-source CBSWs to soil.

5.2 Fertiliser production

fertilizer has been widely used in agriculture to improve the mechanical properties of crops and increase yield.

5.3 Configuring pesticides

6 Conclusions

energy supply landscape and aligned with the “double carbon” strategy. This paper provides an overview of the comprehensive utilization of CBSWs, emphasizing on the need to strengthen research while promote solid waste resource utilization technology. Additionally, the application and promotion to strengthen this technology, as well as means to improve the efficiency and effectiveness of solid waste treatment, increase solid waste treatment efforts and economic income are also highlighted. To address China’s energy structure, often referred to the exchange of the “two

(1) CBSWs is widely used in the building materials industry, agricultural soil improvement and other areas. However, their utilization rate in other highvalue direction such as the extraction of minerals, new materials and catalysis is low. The utilisation process of coal solid waste involves high costs and demands more efficient technical support. Therefore, there is a pressing need to intensify research on the application of this technology. Efforts should be made to simplify the preparation of CBSWs functional materials. Relying solely on a single utilization method will not be sufficient to absorb the vast amounts of CBSWs across the region in a short period. Therefore, it is necessary to explore and establish a multi-industry linkage and collaborative utilization model for CBSWs tailored to local conditions. Elucidating synergistic mechanisms among multiple solid wastes and determining optimal proportions for various applications are essential for achieving high-volume utilization and complementary performance advantages.

(2) The attributes of CBSWs vary greatly from region to region, so a database can be built accordingly. At the same time, a big data management and application platform can be developed to leverage CBSWs. Based on the geographical distribution of CBSWs, coordinate the development relationship of various places, tilt technology and capital to the production area, reduce transportation cost, and drive regional economic development. In addition, explore the joint utilization method of CBSWs and other local wastes, give full play to the synergistic effect of different types of wastes, and realize the comprehensive utilization of various wastes.

(3) Establishing standards and specifications for the entire process, from solid waste raw material selection, production, grading, and storage to application. It is the idea of reducing the generation of CBSWs or reducing part of the energy consumption from the source, and recycling it as much as possible, and the development of high-value characteristic materials for CBSWs. In the future, high value-added CBSWs characteristic materials that take into account cost and performance will be further studied in depth and gradually pushed to industrial testing.

Declarations

References

Ai G, Wang JC, Deng ZX, Shang RY, Chen H (2022) Effect of coal gasification residue with flat mushroom bran application on the number of soil microbial taxa in coal mining areas. Hubei Agric Sci 61:14-18. https://doi.org/10.14088/j.cnki.issn0439-8114. 2022.22.002

and agricultural applications. Water Air Soil Pollut 232:106. https://doi.org/10.1007/s11270-021-05044-z

Bi S (2023) Development and analysis on 2022 titanium dioxide industry in China. Iron Steel Vanadium Titanium 44:1-3. https:// doi.org/10.7513/j.issn.1004-7638.2023.01.001

Bu XN, Ilhwan P, Ugur U (2023) Editorial: advanced green and sustainable chemical and physical technologies for resources recycling of solid wastes. Front Chem 11:1146404. https://doi. org/10.3389/FCHEM.2023.1146404

Chai L, Yue T, Yan ZH, Liu Q, Xiong YS (2023) Research progress on resource utilization of fly ash. China Resour Compr Util 41:93-98. https://doi.org/10.3969/j.issn.1008-9500.2023.02.024

Chang JW, Du GJ, Du JL, Shi XI (2022) Current situation of the comprehensive utilization of coal gangue in china and the related problems and recommendations. China Environ Prot Ind 08:13-17

Chen Q (2012) Preparation of ceramic glazed tiles with cinder. South China University of Technology, Guangzhou

Chen Q (2015) Microstructural analysis of cinder based ceramics. Sci Technol Visio. https://doi.org/10.19694/j.cnki.issn2095-2457. 2015.27.212

Chen Y (2023) Radioactive risk monitoring and analysis of fly ash for wall materials in Guizhou province. China High-Tech 2:8182+88. https://doi.org/10.13535/j.cnki.10-1507/n.2023.12.30

Chen DH, Li C, Zhang ZG (2022) Study on performance optimization of gasification slag based paste filling materials in Ningdong mining area. Coal Geol Explor 50:41-50. https://doi.org/10. 12363/issn.1001-1986.22.05.0385

Chen Z, Zhang ZM, Gui LZ, Sun K, Duan HB, Hu JP, Liang S, Yang JK (2024) Optimization of the the synthesis conditions of zeolite adsorbents derived from fly ash and study on their adsorption performance on benzene. Energy Environ Prot. https://doi.org/ 10.20078/j.eep. 20240701

Cheng JW, Ren WG, Wang JC, Han LN, Chang LP, Bao WR (2019) Extraction of lithium from coal gangue by manganese ion sieve adsorption. Chem Ind Eng Prog 38:3589-3595. https://doi.org/ 10.16085/j.issn.1000-6613.2019-0155

Cheng G, Li YL, Cao YJ, Zhang ZG (2023a) A novel method for the desulfurization of medium-high sulfur coking coal. Fuel 335:126988. https://doi.org/10.1016/j.fuel.2022.126988

Cheng G, Li YL, Zhang MN, Lau EV (2023b) Improving micro-fine mineral flotation via micro/nano technologies. Sep Sci Technol 58:520-537. https://doi.org/10.1080/01496395.2022.2140293

Cheng Y, Zhu HJ, Zhang SJ, Wu HY, Cong JJ, Luo YQ (2023c) Experimental study on preparation of dry-mixed mortar from coal gangue. Coatings 13:518. https://doi.org/10.3390/coatings13 030518

Cheng G, Zhang MN, Lu Y, Zhang HJ, Lau EV (2024) New insights for improving low-rank coal flotation performance via emulsified waste fried oil collector. Fuel 357:129925. https://doi.org/10. 1016/j.fuel.2023.129925

Chi S, Shang BY, Zhang YH, Zhao XS (2023) Preparation of poly aluminum ferric silicate flocculant flocculant from coal gangue for treatment of fluorine chemical wastewaterr. Environm Prot Chem Ind. https://kns.cnki.net/kcms/detail/11.2215.X.20230516. 1843.006.html

Daniyar S, Seon SC, Saken S, Islam O, Zhang D, Ryeol KJ (2022) Preliminary investigation of geopolymer mixture using GGBFS and off-ASTM class F fly ash. Mater Sci Forum 1053:309-314. https://doi.org/10.4028/p-mx9n06

Dhadse S (2024) Utilization of fly ash in agriculture: perspectives and challenges. J Mater Environ Sci 15(7):1038-1050

Dong LP, Xue ZH, Gao F, Yang CY, Li HP, Bao WR, Wang JC, Fan PP (2024) Research on extraction of carbon from coal gasification fine slag using hydrophobic-hydrophilic separation: efficient separation, molecular dynamics simulation, and model optimization. Fuel 365(131180):0016-2361. https://doi.org/10. 1016/j.fuel.2024.131180

Dou ZS, Wei L, Wang M, Wang C, Xl J, Men GY, Li RJ (2024) Feasibility study on using coal gasification slag as substitute for blast furnace slag to prepare super sulphated cement. Bull Chin Ceram Soc 43(08):2952-2960. https://doi.org/10.16552/j.cnki. issn1001-1625.2024.08.009

Du SL, Dong YC, Guo FQ, Tian BL, Mao ST, Qian L, Xin CY (2021) Preparation of high-activity coal char-based catalysts from high metals containing coal gangue and lignite for catalytic decomposition of biomass tar. Int J Hydrogen Energy 46:1413814147. https://doi.org/10.1016/j.ijhydene.2021.01.179

Du YZ, Liu YL, Shen W, Bai Y, Ma H, Tang S, Yao XY, Hao GP (2023) The basic physcial and chemical properties of coal gangue in some typical areas of Shanxi Province. Coal Process Compr Util 285:80-83. https://doi.org/10.16200/j.cnki.112627/td.2023.04.019

Duan YW, Wang PG, Wang Z, Fang T, Dong AZ, Wang A, Lin W, Shi JL, Huang ZL, Hu XY, Li GX (2016) Present research status on extracting gallium from fly ash. Anhui Chem Ind 42:12-14. https://doi.org/10.3969/j.issn.1008-553X.2016.01. 001

Environment-Environmental Protection (2020) Brawijaya university researchers yield new study findings on environmental protection (the possible use of coal fly ash and phosphate-solubilizing fungi for improving the availability of P and plant growth in acid soil). Ecology Environment & Conservation, 42

Estevam ST, de Aquino TF, da Silva TD, da Cruz R, Bonetti B, Riella HG, Soares C (2021) Synthesis of K-merlinoite zeolite from coal fly ash for fertilizer application. Braz J Chem Eng 39:631-643. https://doi.org/10.1007/s43153-021-00172-9

Fan HG, Sun C, Zhao ZT, Han JH (2021) Adsorption properties of zeolite molecular sieves prepared from fly ash. J Jilin Normal Univ (Natural Science Edition) 42:7-10. https://doi.org/10. 16862/j.cnki.ISSN674-3873.2021.01.002

Fan QY, Zhang CY, Geng YQ, Han XN, Chen L (2022) Effects of fly ash application on the properties of coal gangue matrix and plant growth. Sci Soil Water Conserv 20(5):85-92

Fan XP, Liu J, Kang Z, Dong XG (2023) Strategic thinking of comprehensive utilization of coal gangue and ecological restoration of mines. Environ Sanit Eng 31(01):8-15. https:// doi.org/10.19841/j.cnki.hjwsgc.2023.01.002

Feng PF (2020) Progress and development of high value utilization for coal fly ash from power plant. China Resour Compr Util

Figiela B, Korniejenko K, Bulut A, Şahin B, Azizağaoğlu G, Pławecka K, Kozub B (2023) Influence of the size of milled coal gangue particles on the mechanical properties of geopolymers. Mater Proc 13:4. https://doi.org/10.3390/materproc2023013004

Fu Y, Han JM (2023) Methodological breakthrough in the development of thematic publishing in the new era-academic interpretation based on the spirit of the party’s twenty congresses. Science Technol Publ 46:113-121. https://doi.org/10.16510/j.cnki.kjycb. 20230626.007

Gao X (2022) Research on the preparation of high performance ceramic pellets by self-sintering of coal gasification fine slag. Ningxia Univ. https://doi.org/10.27257/d.cnki.gnxhc.2022.001456

Gao JM, Du ZY, Guo YX, Cheng FQ (2021) Progress and prospect of research on comprehensive utilization of coal fly ash for preparation of mullite-based materials. Clean Coal Technol 27:36-47. https://doi.org/10.13226/j.issn.1006-6772.SW201 22901

Gao M, Li MY, Wang JH, Yang PF, Xu MG (2024) Effect of fly ash on properties and hydration of calcium sulphoaluminate cementbased materials with high water content. Rev Adv Mater Sci 63(1):45. https://doi.org/10.1515/RAMS-2024-0046

Gu JR, Liu XM, Zhang ZQ (2023) Road base materials prepared by multi-industrial solid wastes in China: a review. Constr Build Mater 373:130860. https://doi.org/10.1016/j.conbuildmat.2023. 130860

Guo L, Yang YL, Wang HX, Wang YL, Xu YH (2022a) Preparation of porous material with coal gasification slag and its application in treatment of phenol-containing semi-coke wastewater. Coal Chem Ind 50:56-60. https://doi.org/10.19889/j.cnki. 10059598. 2022.05.014

Guo WC, Zhu XB, Zhang ZG, Li W, Zhang CX (2023) Experimental study on extraction aluminum from coal gangue by roasting activation-acid leaching. Coal Conver. https://kns.cnki.net/kcms/ detail/14.1163.TQ.20230322.1551.002.html

Han HJ, Fu BY, Chen FX, Huang SS, Gao YQ, Huang JB, Li JL (2022a) Research progress on extraction of gallium from fly ash. Guangdong Chem Ind 49:79-81

Han HJ, Huang SS, Fu B, Gao YQ, Chen FX, Li JL (2022) Research progress of lithium extraction from fly ash. Modern Chem Res 16-18

He F, Yin XP, Li YW, Wang SR, Dang ZX (2022a) Research progress in stabilized remediation of contaminated soil by solid waste. Modern Chem Res 24:6-9

He ZQ, Ju F, Ning P, Xiao M, Wang TF, Wang D (2022b) Acoustic emission investigation of coal gangue cementitious composites under effects on fiber type. Case Stud Constr Mater 17:e01567. https://doi.org/10.1016/j.cscm.2022.e01567

He XM, Duan XC, Guo W (2023a) Research status and prospect of preparing building materials from coal gangue. Ceram 448:1518. https://doi.org/10.19397/j.cnki.ceramics.2023.02.044

https://www.energyinst.org/statistical-review

Hu D, Fang M, Zhang Q, Jin WQ, Tian Q, Chang X (2020) The method and research progress on the preparation of silica from solid waste. China Resour Compr Util 38:107-109. https://doi.org/ 10.3969/j.issn.1008-9500.2020.10.028

Huang CM (2023) Experimental study on influence of fly ash recycled concrete on mechanical propertie. Brick-Tile. https://doi.org/10. 16001/j.cnki.1001-6945.2023.03.035

Huang MM, Li HX, Liu ZB (2017) Research progress on gallium extraction from different secondary resources. Nonferrous Met Sci Eng 8:21-28. https://doi.org/10.13264/j.cnki.ysjskx.2017. 01.004

Huang QZ, Shi L, He LQ (2021b) Study and application on efficient resource utilization of coal fly ash in agriculture. Non-Metall Mines 44:12-14+18

Jiang YJ (2022a) Study on preparation and performance of mullite porous ceramics from coal gangue. Anhui Univ Sci Technol. https://doi.org/10.26918/d.cnki.ghngc.2022.000463

Jiang XY (2022b) Preparation of hierarchical molecular sieves based on coal gangue and their ad/desorption performance of VOCs. Guangxi Univ. https://doi.org/10.27034/d.cnki.ggxiu.2022. 002489

Jin SX, Zhao ZH, Jiang SF, Sun J, Pan HB, Jiang L (2021) Comparison and summary of relevant standards for comprehensive utilization of fly ash at home and abroad. IOP Conf Ser Earth Environ Sci 621:012006. https://doi.org/10.1088/1755-1315/621/1/012006

Kaman S, Arun K, Alok SK, Ankita A (2023) Fly ash and TiO